The Best Ultimate Guide to Bronze Bushings Materials

Bronze bushings are an important component in a variety of industrial applications, providing vital support and reducing friction to machinery and equipment. The materials used in bronze bushings play an important role in determining their performance and longevity. Next, Come with us to learn about the materials used in bronze bushings, their characteristics, applications, and advantages.

Bronze has excellent mechanical properties as well as resistance to wear and corrosion, making it a versatile and widely used material for bushings. The most common types of bronze used for bushings include phosphor bronze, aluminum bronze, and manganese bronze.

Phosphor bronze is a popular choice for bushing materials due to its high strength, wear resistance and excellent spring properties. It is an ideal material for applications requiring high load-bearing capacity and fatigue resistance. Phosphor bronze bushings are commonly used in heavy machinery, automotive components and industrial equipment where reliable performance is critical.

Aluminum bronze is another widely used casing material known for its exceptional strength, corrosion resistance, and thermal conductivity. This type of bronze is ideal for applications in marine environments, chemical processing and high temperature operations. Aluminum bronze bushings provide superior performance in harsh conditions, making them the first choice for demanding industrial applications.

Manganese bronze, on the other hand, is valued for its high impact strength, wear resistance, and excellent machinability. It is commonly used in applications involving heavy loads, abrasive environments and high-speed operation. Manganese bronze bushings are commonly found in mining equipment, construction machinery and agricultural machinery where durability and reliability are critical.

Factors such as load capacity, operating conditions, temperature changes and environmental exposure must be considered when selecting the appropriate bronze bushing material for a specific application. Understanding the characteristics of each bronze material is critical to making an informed decision to ensure optimal performance and service life of the bushing.

In addition to their mechanical properties, bronze bushings offer several advantages that make them the first choice in various industries. Their self-lubricating properties reduce the need for additional lubrication, resulting in lower maintenance requirements and longer service life. Bronze bushings also have low-friction properties that help improve energy efficiency and smooth operation of machinery and equipment.

Bronze bushings have the characteristics of corrosion resistance and chemical erosion, making them very suitable for applications in harsh and corrosive environments. Their ability to withstand high loads and shock loads makes them ideal for heavy-duty applications where reliability and durability are critical.

In summary, bronze bushing material selection is a critical factor in ensuring optimal performance and longevity of your mechanical equipment. By understanding the properties and benefits of different types of bronze materials, manufacturers and engineers can make informed decisions to meet the specific requirements of their applications. Whether phosphor bronze, aluminum bronze or manganese bronze, each type offers unique advantages to meet a wide range of industrial needs. With the right bronze bushing material, companies can increase the efficiency, reliability and durability of their equipment, ultimately contributing to the success of their overall operations.

Zhejiang MYWAY Co., Ltd.

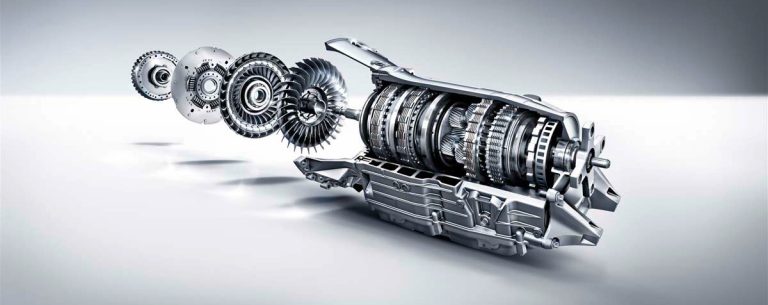

Zhejiang MYWAY Co., Ltd. was established in 2005. It is a professional bushing production company. We have more than 15 years of bushing experience. MYWAY currently has an operation center and three production bases, as well as more than 2,000 bushing molds, the main bushing products include composite bushings, bimetallic bushings, bronze rolled bushings, graphite embedded bushings, special copper bushings, steel bushings, powder metallurgy bushings and other related products. At present, Maiwei has reached in-depth cooperation with leading companies in many industries such as gearbox bushings.

We have to offer:

Stable Quality

Complete range of bushings for transmission/agricultrue machinery/automation etc all kinds of areas

5,000+ pcs of existing molds

Competitive pricing: Raw material producer to better control cost

Profit Concession under currency fluctuations

Other bushing-related content will be updated in the future. You can leave a message if you want to know more.