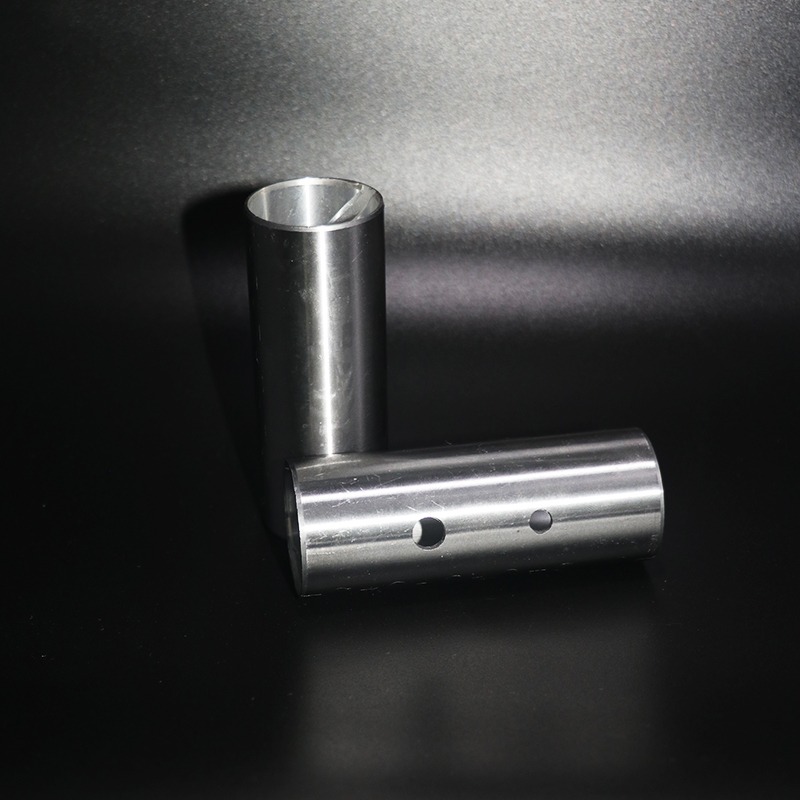

Gearbox bushings play a crucial role in the automotive industry. They are not only key components for smooth operation of the gearbox, but also directly affect the overall performance and driving experience of the vehicle. This article will provide a detailed introduction to the different materials, size choices, and specific usage scenarios of transmission bushings, helping you better understand and choose the appropriate gearbox bushing.

The main materials of the gearbox bushing

The material of the gearbox bushing determines its performance, durability, and applicability. Common gearbox lining materials include the following:

1. Copper alloy bushing

Copper alloy liners are widely used due to their excellent wear resistance and thermal conductivity. Copper alloys have good lubrication properties and can maintain stable performance in high load and high temperature environments. Common types of copper alloys include brass and bronze.

2. Aluminum alloy bushing

Aluminum alloy bushings have the characteristics of light weight and fast heat dissipation, making them suitable for high-performance vehicles that need to reduce vehicle weight. The corrosion resistance of aluminum alloy also makes it perform well in some special environments.

3. Polytetrafluoroethylene (PTFE) bushing

PTFE material has extremely low friction coefficient and excellent chemical corrosion resistance, making it suitable for transmissions in extreme environments. PTFE bushing are typically used in combination with other materials to enhance their mechanical strength.

4. Steel bushing

Steel bushings are widely used in heavy-duty vehicles and industrial equipment due to their high strength and durability. In order to enhance its wear resistance, steel bushing are usually treated with surface treatments such as chrome plating or nitriding.

5. Polymer composite materials bushing

Polymer composite material bushing combine the advantages of multiple materials and have characteristics such as light weight, wear resistance, and chemical corrosion resistance. They are commonly used in high-performance transmissions with strict requirements.

Different sizes of bushings are suitable for different types of transmissions

The size selection of the gearbox bushing needs to be determined based on the specific type and working environment of the gearbox. The following are several common types of transmissions and their applicable bushing sizes:

1. Gearbox Bushing for Manual transmission

The structure of a manual transmission is relatively simple, but it requires frequent shifting, so the lining is required to have high wear resistance and stability. Copper alloy and steel bushings are commonly used in manual transmissions. According to the design of the gearbox, the diameter and length of the lining may vary, usually between 10mm and 50mm.

2. Gearbox Bushing for Automatic transmission

The automatic transmission has a complex structure, including multiple planetary gear sets and a hydraulic torque converter. The lining in an automatic transmission needs to have good heat resistance and corrosion resistance. PTFE and polymer composite material bushing are commonly used in automatic transmissions due to their excellent performance. In terms of size, automatic transmission bushings are usually larger than manual transmissions, with a diameter of up to 100mm or larger.

3. Gearbox Bushing for Continuously variable transmission (CVT)

Continuously variable transmissions require smooth transitions at different speeds, thus requiring extremely high requirements for bushings. Aluminum alloy and polymer composite material bushing have become the preferred choice for CVT transmissions due to their lightweight and high wear resistance. The size of CVT bushings varies depending on design requirements, but the diameter is generally between 20mm and 70mm.

4. Gearbox Bushing for Dual clutch transmission (DCT)

A dual clutch transmission combines the advantages of manual and automatic transmissions, requiring fast and smooth gear shifting. Copper alloy and steel bushings are widely used in DCT transmissions due to their high strength and wear resistance. The size of DCT bushings is usually between manual and automatic transmissions, with a diameter range of 30mm to 80mm.

The performance of bushing in different usage scenarios

Bushings of different materials and sizes perform differently in various usage scenarios:

1. High performance racing cars of gearbox bushing

In high-performance racing, weight and durability are key. Aluminum alloy and polymer composite material bushing have become ideal choices for racing gearboxes due to their lightweight and excellent wear resistance.

2. Commercial vehicles of gearbox bushing

Commercial vehicles such as trucks and buses require bushings to have ultra-high wear resistance and load-bearing capacity. Steel and copper alloy bushings are widely used in the transmissions of these heavy-duty vehicles due to their high strength and stability.

3. Off road vehicles of gearbox bushing

Off road vehicles typically operate in harsh environments, requiring bushings to have good corrosion resistance and wear resistance. PTFE and polymer composite material bushing are suitable for transmissions in off-road vehicles due to their excellent chemical corrosion resistance and wear resistance.

4. Daily family sedan of gearbox bushing

The requirements for lining in daily family cars are relatively balanced, and durability and economy are key. Copper alloy and polymer composite material bushing are widely used in transmissions of household cars due to their excellent comprehensive performance.

conclusion

The material and size selection of the gearbox bushing are key to ensuring smooth operation and long service life of the gearbox. Understanding the characteristics and applicable scenarios of different materials can help you make the best choice when maintaining and replacing transmission bushings. Whether it’s high-performance racing cars, commercial vehicles, off-road vehicles, or family sedans, choosing the right lining can significantly improve the overall performance and driving experience of the vehicle.