Bushing is a mechanical component widely used in various mechanical equipment, especially in the fields of engineering machinery and construction machinery. It is usually used to reduce friction, enhance wear resistance, and improve the service life of mechanical equipment. The following is a detailed introduction to liner products:

What is a bushing?

A bushing is a mechanical component similar to a bearing, usually made of metal or plastic, used to provide support and reduce friction between mechanical parts. It can be an independent part or embedded in other components.

Type of bushing

Metal bushing:

Usually made of bronze, aluminum alloy, or steel, suitable for high loads and high temperature environments.

Plastic bushing:

Usually made of nylon, polytetrafluoroethylene (PTFE) or other engineering plastics, with good corrosion resistance and self-lubricating properties.

Composite bushing:

Composed of multiple materials, combining the advantages of different materials to provide better performance.

Application of Bushing

Bushing is widely used in various mechanical equipment, especially in the following fields:

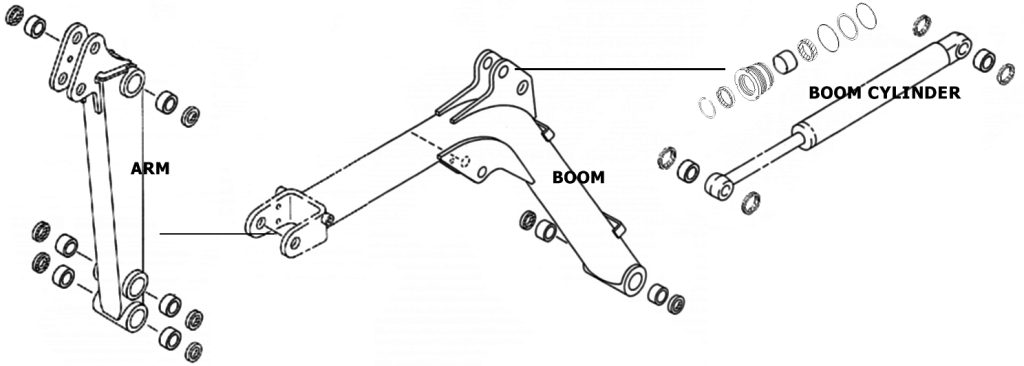

Construction machinery: such as excavators, bulldozers, loaders, etc., with bushings used for joints, hinges, and rotary supports.

Automotive industry: used in engines, transmission systems, and suspension systems to reduce friction and wear.

Industrial equipment, such as pumps, valves, and compressors, are supported by bushings between sliding and rotating components.

Agricultural machinery: such as tractors, harvesters, etc., with bushings used for various rotating and sliding components.

Advantages of Bushing

Reducing friction: Bushing can reduce friction between mechanical parts and extend the service life of equipment.

Improving wear resistance: High quality lining materials can significantly improve the wear resistance of equipment.

Reduce maintenance costs: Using bushings can reduce the frequency and cost of equipment maintenance.

Improving equipment performance: Bushing can improve the smoothness and accuracy of mechanical equipment operation.

Selection of Bushing

When selecting a bushing, the following factors need to be considered:

Working environment: including factors such as temperature, humidity, and corrosiveness.

Load requirements: Consider the load conditions of mechanical equipment, including static and dynamic loads.

Material performance: Select suitable materials to meet the requirements of wear resistance, corrosion resistance, and self-lubricating properties.

Dimensions and tolerances: Ensure that the dimensions and tolerances of the lining comply with the design requirements of the mechanical equipment.

Summary

Bushing, as a key mechanical component, plays an important role in various types of mechanical equipment. Choosing and using bushings correctly can significantly improve the performance and service life of mechanical equipment, and reduce maintenance costs. In practical applications, it is necessary to choose the appropriate type and material of lining according to specific working conditions and requirements.

Do you want to learn more about specific types of bushings or their application scenarios?