About US

Zhejiang Myway Co., Ltd.

Chinese Bushings Manufacturing for Over 20+ Years

Zhejiang Myway Co., Ltd.

We offer recent fast, professional and execeptional services

All types of self-lubricating bushing

Raw material die casting line

Product and material research and development

drawing production Productand brand customization

Automated production line

drawing production Productand brand customization

Our factory

Bushings Manufacturer from raw material casting to finish products

Casting Workshop

Processing Workshop

Inspection Workshop

Finished Goods Warehouse

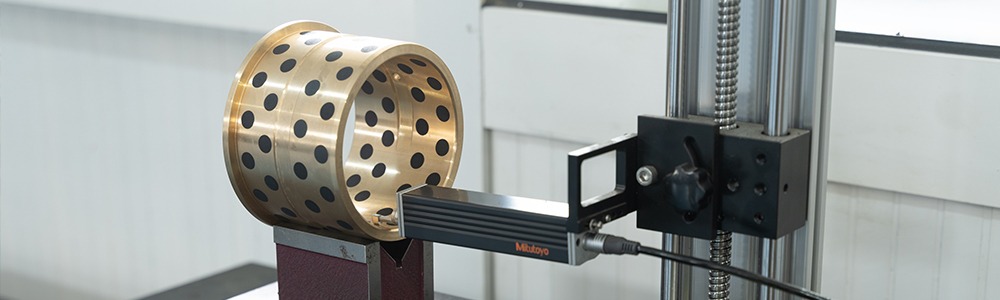

about Our equipment

Perfect quality control means, testing equipment,and multi specification production equipmen

Coordinate Measuring Machine (CMM)

CMM (Coordinate Measuring Machine)is a detector with three directions of movement, can move on three perpendicular rails, the detector transmits signals in contact or non-contact, and the three-axis displacement measurement system (such as an optical ruler) calculates the coordinates of each point of the workpiece (X, Y, Z) and various functions of the instrument measured by the data processor or computer.

The measurement function of the coordinate measuring instrument should include dimensional accuracy measurement, positioning accuracy measurement, geometric accuracy measurement and contour accuracy measurement. Any shape is composed of three-dimensional space points, and all geometric measurements can be reduced to the measurement of three-dimensional spatial points, so accurate acquisition of spatial point coordinates is the basis for evaluating any geometric shape.

Large Copper Bushing Processing Equipment

The maximum processing diameter is 1200-2500mm