Add Your Heading Text Here

We provide high-quality, low-noise, long-life, multi category, and multi-purpose bushings.

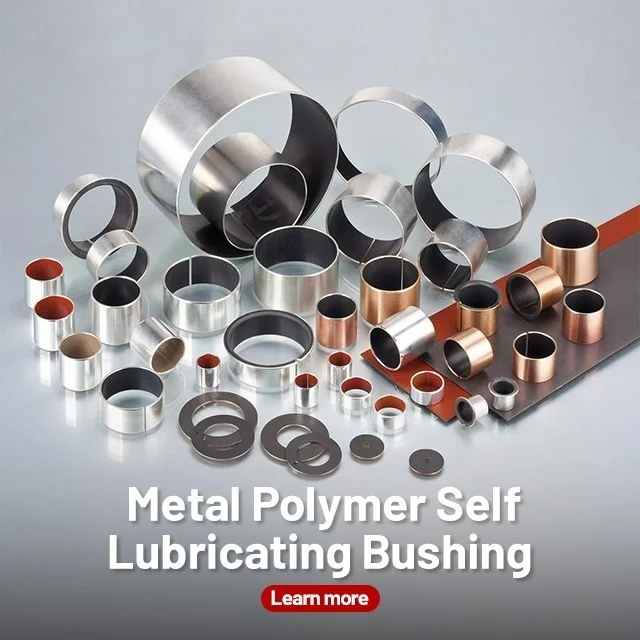

Self-lubricating multilayer composite bushing

Three-layer composite: steel plate layer, copper powder layer, plastic layer. The steel plate layer plays the role of assembly and positioning, bearing pressure; the copper powder layer plays the role of connecting the plastic and auxiliary friction reduction; the plastic layer plays the role of wear-resistant and self-lubricating. Its advantage is that it can be self-lubricating when there is no oil, low noise when working, thin-wall design structure with small volume, and wear-resistant can keep long-term non-wear. It is a new type of bearing to replace needle roller bearings, oil bearing and copper alloy bearings. The advantages of this series of bearings of our company are the use of high-end equipment in the production process, strong automatic production capacity, small wall thickness tolerance, high precision, advanced product formulation technology, and according to the customer’s personalized needs, simulation tests of working conditions. The product quality and development technology are at the international advanced and domestic leading level.

Boundary lubricating bushing

Three-layer composite: steel plate layer, copper powder layer, plastic layer. The steel plate layer plays the role of assembly and positioning, bearing pressure; the copper powder layer plays the role of connecting the plastic and auxiliary friction reduction; the plastic layer plays the role of wear-resistant and self-lubricating. Its advantage is that it can be self-lubricating when there is no oil, low noise when working, thin-wall design structure with small volume, and wear-resistant can keep long-term non-wear.

Bimetal bushing

Solid lubricating bushing

Three-layer composite: steel plate layer, copper powder layer, plastic layer. The steel plate layer plays the role of assembly and positioning, bearing pressure; the copper powder layer plays the role of connecting the plastic and auxiliary friction reduction; the plastic layer plays the role of wear-resistant and self-lubricating. Its advantage is that it can be self-lubricating when there is no oil, low noise when working, thin-wall design structure with small volume, and wear-resistant can keep long-term non-wear. It is a new type of bearing to replace needle roller bearings, oil bearing and copper alloy bearings. The advantages of this series of bearings of our company are the use of high-end equipment in the production process, strong automatic production capacity, small wall thickness tolerance, high precision, advanced product formulation technology, and according to the customer’s personalized needs, simulation tests of working conditions. The product quality and development technology are at the international advanced and domestic leading level.

Wrapped bronze bushing

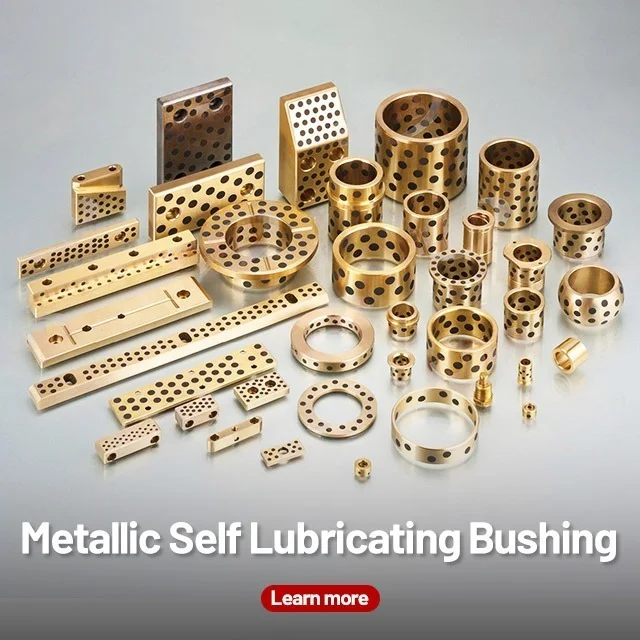

Metallic SelfLubricating Bushing

Steel bushing

Three-layer composite: steel plate layer, copper powder layer, plastic layer. The steel plate layer plays the role of assembly and positioning, bearing pressure; the copper powder layer plays the role of connecting the plastic and auxiliary friction reduction; the plastic layer plays the role of wear-resistant and self-lubricating. Its advantage is that it can be self-lubricating when there is no oil, low noise when working, thin-wall design structure with small volume, and wear-resistant can keep long-term non-wear. It is a new type of bearing to replace needle roller bearings, oil bearing and copper alloy bearings. The advantages of this series of bearings of our company are the use of high-end equipment in the production process, strong automatic production capacity, small wall thickness tolerance, high precision, advanced product formulation technology, and according to the customer’s personalized needs, simulation tests of working conditions. The product quality and development technology are at the international advanced and domestic leading level.

Powder Metallurgy

Three-layer composite: steel plate layer, copper powder layer, plastic layer. The steel plate layer plays the role of assembly and positioning, bearing pressure; the copper powder layer plays the role of connecting the plastic and auxiliary friction reduction; the plastic layer plays the role of wear-resistant and self-lubricating. Its advantage is that it can be self-lubricating when there is no oil, low noise when working, thin-wall design structure with small volume, and wear-resistant can keep long-term non-wear. It is a new type of bearing to replace needle roller bearings, oil bearing and copper alloy bearings. The advantages of this series of bearings of our company are the use of high-end equipment in the production process, strong automatic production capacity, small wall thickness tolerance, high precision, advanced product formulation technology, and according to the customer’s personalized needs, simulation tests of working conditions. The product quality and development technology are at the international advanced and domestic leading level.