With technology advancing continuously, the use of composite materials is becoming more widespread across various fields. Composite bushings have emerged in mechanical manufacturing and engineering due to their unique performance advantages. This article explores the characteristics, advantages, and applications of composite bushings. Additionally, it highlights how these bushings have the potential to significantly improve equipment performance.

1. Introduction to Composite bushing Materials

Composite bushings, made from combined materials, offer excellent performance. Consequently, they are utilized across mechanical, automotive, and aerospace industries.

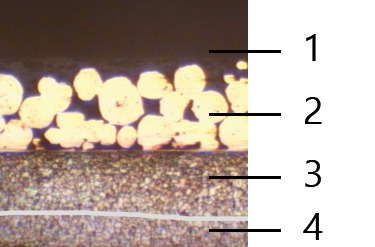

2. Characteristics of composite material bushing

Composite bushings are strong and lightweight, reducing equipment weight and improving efficiency.

Composite materials offer wear and corrosion resistance, extending bushing life and reducing maintenance costs.

Some composite bushing are self-lubricating, reducing lubricant use and improving equipment stability.

Composite materials reduce vibration and noise, enhancing equipment comfort and safety.

3. Advantages of composite bushing materials

Composite bushings can be customized for specific applications; thus, they can meet various environmental and operational requirements.

High reliability: Due to the excellent performance of composite material liners, their service life is longer and their reliability is higher than traditional materials.

Although composite bushings have a high initial cost, their low long-term usage cost reduces equipment downtime and maintenance, offering significant economic benefits.

Environmental friendliness: Composite material liners can reduce environmental pollution during production and use, meeting modern environmental requirements.

4. Application of composite material bushing

Composite bushings enhance performance and reliability in transmission systems, hydraulic systems, and engineering machinery. Consequently, they contribute to the overall efficiency and longevity of these systems.

In automobile manufacturing, composite bushings reduce vehicle weight and improve fuel efficiency. As a result, they enhance performance in engines, transmissions, and suspension systems.

In the aerospace industry, composite liners serve as critical components for aircraft and spacecraft. Consequently, they enhance both safety and durability.

In the chemical, petroleum, metallurgical, and other industrial fields, composite material liners not only maintain stable performance in harsh environments but also extend the service life of equipment.

5. Future Development Trends

With the continuous development of composite material technology, composite material liners are expected to become lighter, stronger, and more intelligent in the future. The application of new materials and manufacturing processes will further enhance the performance of composite bushing materials, bringing more innovative solutions to various industries.

Conclusion

Composite bushing, as a new type of material that combines the advantages of multiple materials, is gradually changing the production and application methods in various fields due to its excellent performance and wide application prospects. By gaining a deeper understanding and application of composite bushing materials, enterprises can improve equipment performance, reduce costs, and achieve sustainable development. I hope this article can provide you with valuable information to assist in your production and application practices.