Do you know about oil free bushings?

一、What is an oil-free bushing

Oil-free bushings are also known as oil-free bearings. This product is a self-lubricating bearing among sliding bearings.

It is a novel lubricating bearing that combines the characteristics of metal bearings and oil-free lubricating bearings. The metal bears the load, and the specially formulated solid lubricating material acts as lubrication, which results in strong load-bearing capacity, high temperature resistance, impact resistance, and self-lubricating capabilities. Strong characteristics.

It is especially suitable for heavy loads, low speeds, reciprocating or swinging situations where it is difficult to lubricate and form an oil film. It is also not afraid of corrosion and erosion by water flushing and other acids.

二、Characteristics of oil-free bushings

01. Low maintenance frequencies can be used for both linear motion and rotational motion

02. Can be used under harsh conditions of high and low temperatures

03. Compared with linear bearings, the bushing is thinner and saves space

04. Compared with ball-type linear bearings, oil-free bushings are suitable for low-speed and heavy-load applications

三、Classification of oil-free bushings

Composite bushing (SF-1/SF-2)

The steel plate layer plays the role of assembly positioning and bearing pressure; the copper powder layer plays the role of connecting plastics and auxiliary friction reduction;

Advantage: it can be self-lubricated even when there is no oil, it has low noise during operation, its thin-wall design structure is small, and its wear resistance can maintain long-term wear-free. It is a new type of bearing that replaces needle roller bearings, oil bearings and copper alloy bearings.

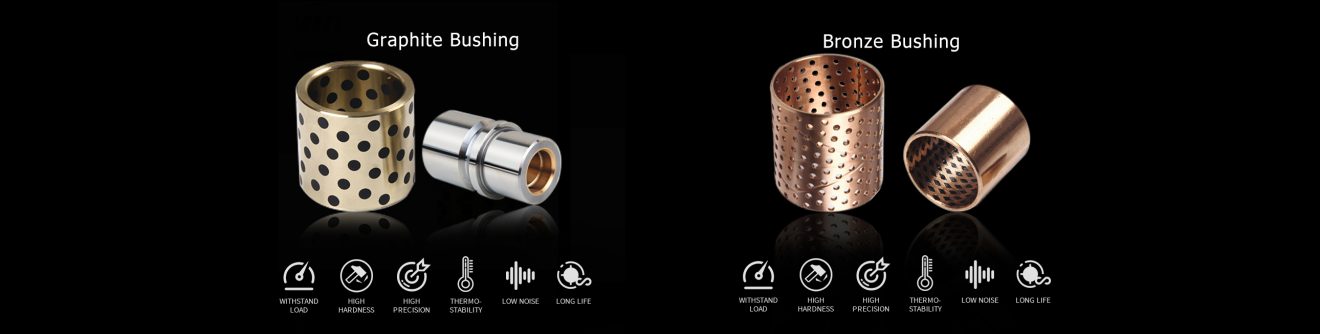

Bronze Bushing

Using a specially formulated high-density copper alloy strip as the base, the surface can be rolled with diamond-shaped or hemispherical oil holes and oil grooves according to user requirements.

Advantage: high density, large load-bearing pressure, good wear resistance, and long service life. It can replace the traditional cast copper sleeve, reduce the size of the machine, and reduce the cost. It can also be made into bearing bushes, flanged bushings, thrust washers and ball bowls.

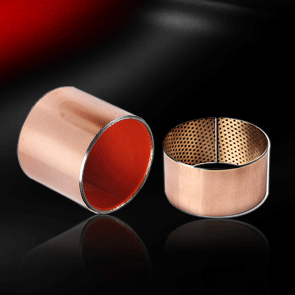

Bimetal Bushing

The outer surface of the bearing is made of steel and the inner surface is sintered bronze alloy. The solid lubricant is evenly distributed in the alloy layer. When used in oily conditions, it can replace copper sleeves, babbitt alloy and roller bearings

Advantage: low cost, thin-walled design, small structure, good wear resistance and good lubricity. Various forms of oil grooves and oil holes are designed according to the lubrication conditions provided by customers, and it can be adapted to mass production.

Graphite Bushing

High-strength metal matrix embedded with solid lubricant. It has obvious advantages when used under high load-bearing and oil-free conditions. It can replace rolling bearings and copper alloy bearings in high-pressure, high-temperature and high-precision situations

Advantage: cost-effective, highly adaptable, wear-resistant, and has excellent axial and radial load capacity. JDB products can be used in environments that general copper sleeves cannot meet to solve special needs.

Solid Special Bronze Bushing

Based on copper alloy

Advantage: It can achieve micro operation and has excellent sintering resistance. It is suitable for low load and high speed operation and has better performance under oil and lubrication conditions

Steel Bushing

It can well avoid the lubrication blind area on the inner surface of the shaft sleeve, the hesitation axis is densely covered, and the oil storage is rich. It can effectively reduce the time between refueling.

Advantage: Has high pressure resistance. Wear-resistant and excellent lubrication properties, able to withstand axial force, corrosion-resistant, high transmission accuracy, more economical and affordable than copper alloy type, mostly used in medium-load and low-speed working conditions

四、Zhejiang MYWAY Co., Ltd.

Zhejiang MYWAY Co., Ltd. was established in 2005. It is a professional bushing production company. We have more than 15 years of bushing experience. MYWAY currently has an operation center and three production bases, as well as more than 2,000 bushing molds, the main bushing products include composite bushings, bimetallic bushings, bronze rolled bushings, graphite embedded bushings, special copper bushings, steel bushings, powder metallurgy bushings and other related products. At present, Maiwei has reached in-depth cooperation with leading companies in many industries such as gearbox bushings.

We have to offer:

Stable Quality

Complete range of bushings for transmission/agricultrue machinery/automation etc all kinds of areas

5,000+ pcs of existing molds

Competitive pricing: Raw material producer to better control cost

Profit Concession under currency fluctuations

Other bushing-related content will be updated in the future. You can leave a message if you want to know more.