20 important applications of the self-lubricating bearing

Self-lubricating Bearing have emerged as a result. With the continuous progress of science and technology today, mechanical technology is developing towards advanced, cutting-edge, and diversified trends. Especially in research fields such as aerospace, military, and nuclear energy, bearing technology faces many new challenges, such as the use of bearings in extreme environments such as high and low temperatures, vacuum, etc.

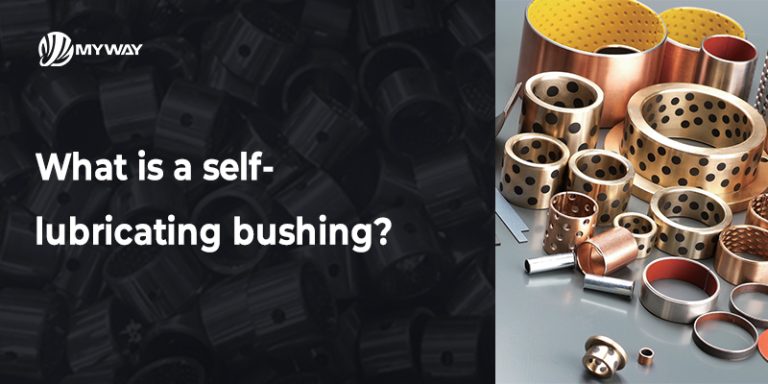

Generally, sliding bearings lubricated with bearing materials, bearing material components, or solid lubricants are called self-lubricating bearings. From the perspective of lubrication mechanism, it can generally be divided into two types: bearings with self-lubricating properties generated by the self-lubricating material itself and bearings with self-lubricating properties generated by the properties of sintered microporous materials.

MYWAY’s metal polymer three-layer self-lubricating bearing series is based on metal materials, with a sintered porous copper powder layer in the middle and a surface covered with PTFE and thermoplastic polymers as the bearing working layer. The use of this material endows bearings with excellent mechanical load-bearing performance, while the copper powder layer can transfer the heat generated during bearing operation and improve the bonding strength between polymers and substrates; The design and application of PTFE can enable bearings to be used in completely dry friction environments, while the use of thermoplastic polymer materials can enable bearings to be used in boundary lubrication operating conditions.

The MYWAY metal polymer 3-layer self-lubricating bearing series is widely used and can be used for:

1. Self-lubricating Bearing for Hydraulic and pneumatic industry

Gear pump shaft sleeve, guide and fulcrum parts for liquid and cylinder.

2. Forging and pressing machine tool industryhanism, etc

3. Lubricating Bearing for Plastic machinery industry

Plastic injection mobile template skateboard sliding, injection seat sliding, and automatic discharge mechanism.

4. Self- lubricating Bronze Bearing for Lifting and handling machinery

Manual hydraulic transport vehicle, hydraulic lifting platform, forklift, pulley elevator, three-dimensional parking garage, stage equipment, etc.

5. Lubricating Bearing for Port machinery

Hoists, winch brake mechanisms, container lifting tools (clamps, cranes, shovels), etc.

6. Lubricating Bearing for Office and fitness machinery

The sliding and rotating parts of combination fitness equipment such as swivel chair adjustment mechanism, treadmill, rowing machine, etc.

7. Lubricating Bearing forTextile machinery

Spinning machines, twisting machines, carding machines, weaving machines, dobby machines, warp knitting machines, punching machines, pasting machines, spinning machines, etc.

8. Self-lubricating Bearing for Food packaging filling machinery

The door hinges and chain joints of baking ovens (ovens) for biscuits, bread, etc., as well as the sealing, cutting, and feeding transmission mechanisms of fully automatic food (fast food) packaging and filling machinery.

9. Lubricating Bearing for Chemical machinery

Chemical raw material conveying pumps (centrifugal pumps, reciprocating pumps, gear pumps, axial flow pumps, pipeline pumps, etc.), as well as the positioning of the stirring mechanism in the reaction kettle.

10. SF-1 Bushing for Printing, packaging and papermaking machinery

Various paper feeding parts of printing machines, including flat press hot stamping, embossing machine hot stamping, paper feeding transmission parts, paper making machinery drying line drum parts, winding machines, paper cutting machines, packaging machines, etc.

11. SF-1 Bushing for Automobile, railway locomotive, shipbuilding industry

Shock absorbers, engine hood, luggage compartment lid hinges, steering mechanism, brake linkage device, suspension arm joint (connecting shock absorbers), parking mechanism, seat adjustment mechanism, railway turbine car balance arm and nose connection mechanism, automatic door switch device, ship steering gear (steering linkage group), hatch cover, machinery, automotive production line, automotive paint baking device, etc.

12. Self-lubricating Bearing for Agricultural machinery

Combine harvesters, transplanters, seeders, cultivators, dryers, tea makers, etc.

13. Self-lubricating Bearing for Construction machinery

Crawler type sports machinery with supporting wheels, cement mixer, concrete conveying pump, winch brake mechanism, etc.

14. Self-lubricating Bearing for Metallurgy and Casting Machinery

Casting mold automatic forming machine and its unit, etc.

15. Self lubricating Bearing for Environmental protection machinery

Garbage collection and processing machinery, etc.

16. Self-lubricating Bearing for for Woodworking Machinery

Plywood press, planer, gluing machine, blooming machine, band saw machine, bending machine, etc.

17. SF-1 Bushing for Household appliances and furniture

Vortex air conditioning compressor, copier paper feeding mechanism, camera, typewriter, vacuum cleaner, electric oven door hinge, dishwasher, etc.

18. Self-lubricating Bearing for Robots

Automated mechanical equipment (stretching, swinging, sliding, bending, rotating, etc.).

19. Self lubricating Bearing for Machine tool

Lathe, grinder, milling machine, grinder, sawing machine, drilling machine, polishing machine, conveyor (automatic feeding mechanism), etc.

20. SF-1 Bushing for General industrial machinery and equipment

Gearboxes, continuously variable transmissions, cable production machinery, weight analysis devices, heat treatment furnaces, drying machinery, medical machinery, valves and their driving mechanisms, pharmaceutical machinery, etc.