Quality Materials Bushings of the Komatsu Excavator

Komatsu excavators are renowned for their durability and efficiency, crucial to which are the bushings used in various parts of the machine. Bushings, or bearings, are integral components that significantly enhance the performance and lifespan of excavators by reducing friction and wear between moving parts.

Materials Used in Komatsu Excavator Bushings

Bronze:

Composition: Copper-tin alloy, sometimes with added elements like phosphorus, lead, or zinc.

Properties: Excellent wear resistance, good strength, and high load-carrying capacity.

Applications: Often used in high-stress areas due to its durability and ability to withstand heavy loads.

Steel:

Composition: Typically hardened steel with a specific heat treatment to enhance its hardness and wear resistance.

Properties: High strength, excellent durability, and resistance to deformation under heavy loads.

Applications: Commonly used in areas that experience significant impact and stress, such as the boom, arm, and bucket pivots.

Composite Materials:

Composition: A combination of metal and non-metal materials, such as PTFE (Polytetrafluoroethylene) or other engineered plastics.

Properties: Low friction, self-lubricating, and high resistance to wear and corrosion.

Applications: Ideal for areas where lubrication is difficult or where the bushing needs to operate in harsh environments.

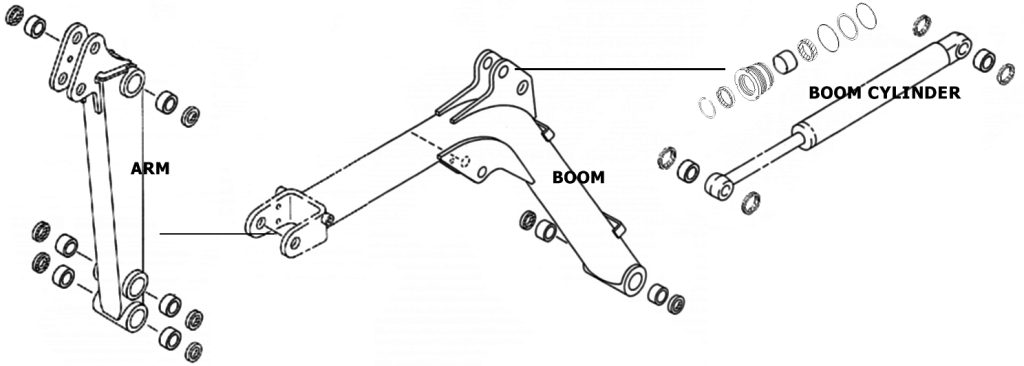

Application Areas in Komatsu Excavators

Boom and Arm Joints:

Bushings here help in smooth articulation and bear the brunt of lifting and digging forces.

Bucket Pins:

These bushings ensure smooth movement and reduce wear between the bucket and the arm, which is crucial for efficient digging operations.

Swing Bearing:

Located in the swing mechanism, these bushings facilitate smooth rotation of the excavator’s upper structure.

Track Rollers and Idlers:

Bushings in these areas help in smooth and efficient movement of the tracks, ensuring stability and mobility.

Core Considerations for Bushings

Durability:

The bushing material must withstand continuous wear and tear, as well as exposure to harsh working conditions.

Load Capacity:

Bushings should be able to bear heavy loads without deforming, which is crucial for the excavator’s operational efficiency.

Maintenance:

Easy maintenance and replacement are important to minimize downtime and extend the machine’s service life.

Lubrication:

Proper lubrication is essential to reduce friction and prevent premature wear. Some bushings are self-lubricating, reducing the need for regular maintenance.

Corrosion Resistance:

Bushings must resist corrosion, especially when used in environments with high moisture or chemicals.

In summary, the selection and application of bushings in Komatsu excavators are critical for maintaining the machinery’s performance and longevity. By choosing the right materials and focusing on key factors like durability, load capacity, and maintenance, operators can ensure their excavators operate smoothly and efficiently under demanding conditions.