How to Replace Komatsu Excavator Bushings

Replacing bushings in your Komatsu excavator is crucial for maintaining optimal performance and prolonging the machine’s lifespan. This guide provides a step-by-step process to ensure a smooth and effective bushing replacement.

Why Replace Komatsu Excavator Bushings?

Bushings reduce friction between moving parts, support heavy loads, and withstand harsh working conditions. Over time, wear and tear can lead to decreased performance and potential damage to other components. Regularly replacing bushings helps:

Maintain Efficiency: Ensure smooth operation and reduce downtime.

Extend Lifespan: Protect other components from excessive wear.

Safety: Prevent unexpected breakdowns and ensure safe operation.

Signs It’s Time to Replace Bushings

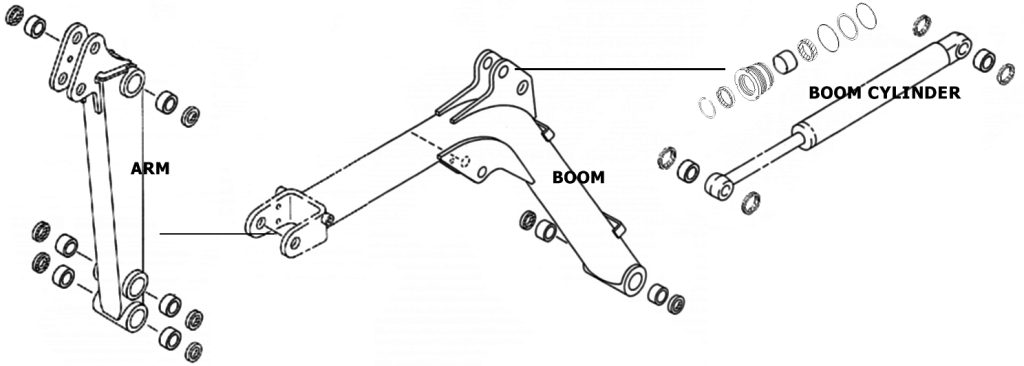

Increased Play: Noticeable looseness in the boom, arm, or bucket.

Unusual Noises: Squeaking or grinding sounds during operation.

Visual Wear: Visible wear or deformation on the bushings.

Performance Issues: Reduced efficiency or increased fuel consumption.

Tools and Materials Needed

New bushings (compatible with your specific Komatsu model)

Hydraulic press or bushing removal tool

Wrenches and socket set

Lubricant

Cleaning supplies

Step-by-Step Replacement Process

Safety First

Park the excavator on a level surface and engage the parking brake.

Turn off the engine and disconnect the battery to avoid accidental startup.

Wear appropriate safety gear, including gloves and safety glasses.

Remove the Old Bushings

Turn off the engine and disconnect the battery to avoid accidental startup.

Remove the Old Bushings

Check the surrounding components for wear or damage. Replace any worn parts as necessary to prevent future issues.

Install the New Bushings

Apply a thin layer of lubricant to the new bushings.

Align the new bushings with the housing and press them into place using a hydraulic press or bushing installation tool.

Ensure the bushings are seated properly and securely.

Reassemble and Test

Reassemble any parts that were removed during the bushing replacement.

Reconnect the battery and start the engine.

Test the excavator to ensure smooth operation and check for any unusual noises or movements.

Maintenance Tips for Longevity

Regular Inspections: Frequently check bushings and other components for signs of wear.

Proper Lubrication: Ensure all moving parts are adequately lubricated to reduce friction and wear.

Timely Replacements: Replace bushings as soon as signs of wear appear to prevent further damage.

Conclusion

Replacing bushings in your Komatsu excavator is a vital maintenance task that ensures optimal performance and extends the machine’s lifespan. By following this comprehensive guide, you can effectively replace worn bushings and keep your excavator running smoothly. Regular inspections and timely maintenance will help you avoid costly repairs and downtime, keeping your operations efficient and safe.