The Key to Machine Life: The Importance of Quality Bushing

In the daily operation of mechanical equipment, the lining plays a crucial role as a critical component. Bushing not only reduces friction and protects other components, but also extends the overall service life of the equipment. This article will explore in detail the importance of bushings and their key role in improving equipment life.

What is a bushing?

Bushing is a type of support and anti friction component used in mechanical equipment, usually made of metal or plastic materials. It is designed to be installed inside the hole to protect the contact surface between the hole wall and the shaft, reducing friction and wear. This type of component is widely used in various fields such as engineering machinery, automobiles, and industrial equipment.

The Importance of Bushing

Reduce friction and wear

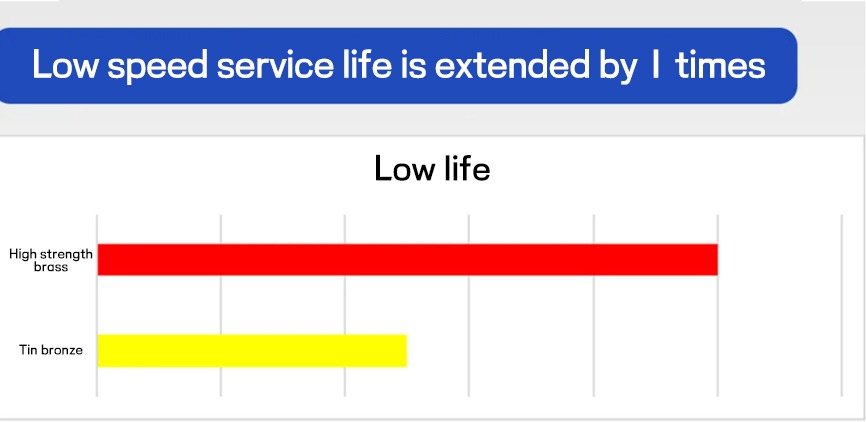

The main function of the bushings is to reduce friction and wear between mechanical components. When the shaft rotates or slides in the hole, the Self lubricating bearing provides a smooth contact surface, making the movement smoother. By reducing friction, the lining can significantly reduce the wear of mechanical parts and extend their service life.

Improve the accuracy of mechanical equipment

Due to its ability to provide stable support, the bushings plays an important role in maintaining the accuracy of mechanical equipment. High precision equipment not only runs more smoothly, but also improves production efficiency and product quality. Therefore, the use of high-quality Self lubricating bearing in high-precision equipment is crucial.

Protecting other components

Bushing can absorb and disperse the load generated during the operation of mechanical equipment, protecting other key components from damage. For example, in construction machinery such as excavators and bulldozers, Self lubricating bearing can protect hinge and joint parts from excessive wear and failure.

Reduce maintenance costs

By using durable and high-quality bushings, the maintenance frequency and cost of mechanical equipment can be significantly reduced. Self lubricating bearing not only prolongs the service life of components, but also reduces the frequency of replacement and maintenance, thereby lowering the total cost of ownership.

How to choose the appropriate lining?

Select materials based on working conditions

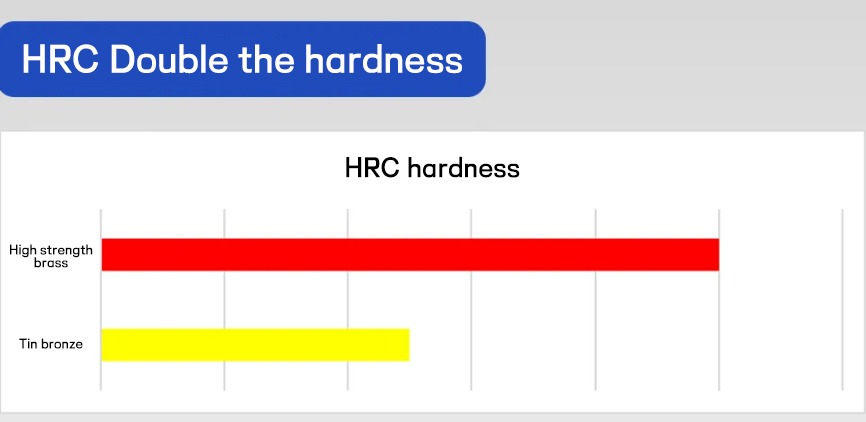

Bushings of different materials are suitable for different working conditions. Metal bushings (such as bronze or steel) are suitable for high load and high temperature environments, while plastic Self lubricating bearing (such as nylon or PTFE) are suitable for environments that require corrosion resistance and self-lubricating properties. Choosing appropriate materials based on specific working conditions can better utilize the function of the lining.

Consider load and speed

When selecting Self lubricating bearing , it is necessary to consider the load and operating speed of the equipment. High load and high-speed applications require the use of wear-resistant and high-strength bushings to ensure long-term stable operation.

Ensure dimensional and tolerance accuracy

The size and tolerance of the lining have a significant impact on the operational performance of the equipment. Choosing bushings with dimensions and tolerances that meet the requirements can ensure the installation and operation accuracy of the equipment, thereby improving the overall performance of the equipment.

Summary

As a key component in mechanical equipment, bushings significantly improve the service life of equipment by reducing friction and wear, improving equipment accuracy, protecting other components, and reducing maintenance costs. When selecting and using Self lubricating bearing, appropriate materials and specifications should be selected based on specific working conditions and needs to fully leverage their advantages.

I hope this article can help you better understand the importance of Self lubricating bearing and make wiser choices in practical applications. If you have any further questions or needs about the lining, please feel free to contact us at any time. We will wholeheartedly provide you with professional