bushings or bearings: How to choose which one

In the field of mechanical equipment, bushings and bearings are crucial components. Although they have similarities in functionality, there are significant differences in application scenarios and performance characteristics. This article will delve into the differences between bushings and bearings, helping you better understand their uses and selection guidelines.

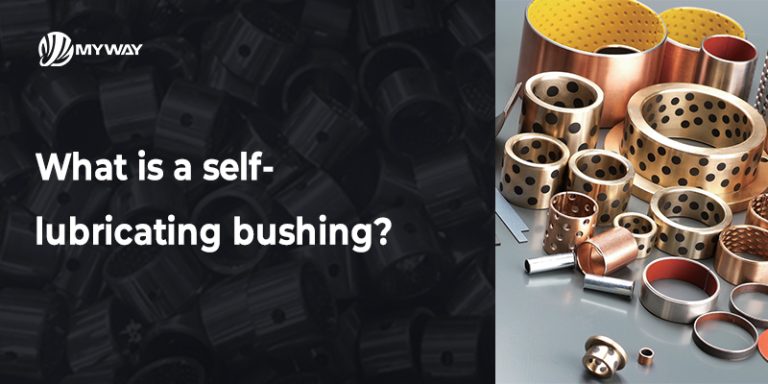

What is a bushing?

Bushing is a type of support and anti friction component used in mechanical equipment, usually made of metal or plastic materials. Its main function is to reduce friction between mechanical components and extend the service life of the equipment. Bushing is commonly used in fields such as construction machinery, automobiles, and industrial equipment.

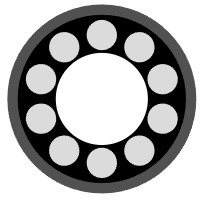

What is a bearing?

Bushing is a type of support and anti friction component used in mechanical equipment, usually made of metal or plastic materials. Its main function is to reduce friction between mechanical components and extend the service life of the equipment. Bushing is commonly used in fields such as construction machinery, automobiles, and industrial equipment.

Structure and Design

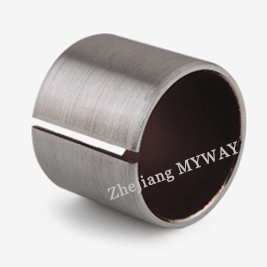

Bushing

Usually a simple cylindrical or other geometric shape, with a relatively simple structure, mainly reducing friction through the characteristics of the material itself.

Bearing

The structure is relatively complex, including multiple components such as the outer ring, inner ring, and rolling element. The design is more precise and can withstand higher loads and speeds.

Working principle

Bushing

Reduces friction through the self-lubricating properties of materials or the addition of lubricants, suitable for low-speed and light load working conditions.

Bearing

Reduce friction through rolling or sliding contact of rolling elements, and can work stably under high load and high-speed conditions.

Maintenance and service life

Bushing

Maintenance is relatively simple, usually only requiring regular inspection and replacement of lubricants, and its service life is greatly affected by materials and working environment.

Bearing

Maintenance is complex and requires regular inspection of the rolling elements and lubrication system. They have a long service life, but once damaged, the cost of replacement is high.

How to choose a suitable bushing or bearing?

1. Working conditions

Select appropriate components based on the working environment, load, and speed of the equipment. For high load and high-speed applications, bearings are preferred; For low-speed, light load, and corrosion-resistant environments, bushings can be selected.

2. Material requirements

Consider the temperature, humidity, and corrosiveness of the usage environment, and select appropriate materials. For example, bronze bushings are suitable for high-temperature environments, while nylon bushings are suitable for humid environments.

3. Cost budget

Taking into account both the initial cost and maintenance cost of the components. Although the initial cost of bearings is relatively high, their service life and performance are usually better; The initial cost of the lining is relatively low, making it suitable for projects with limited budgets.

Summary

As key components in mechanical equipment, bushings and bearings each have their unique advantages and application scenarios. Understanding their differences and characteristics can help make the best choices when designing and maintaining mechanical equipment. Whether it is high load and high-speed application requirements, or low speed and light load working environments, reasonable selection and use of bushings or bearings can significantly improve the performance and service life of equipment.

I hope this article can help you better understand the difference between bushings and bearings, and make wiser choices. If you have any further questions about bushings or bearings, please feel free to contact us at any time.