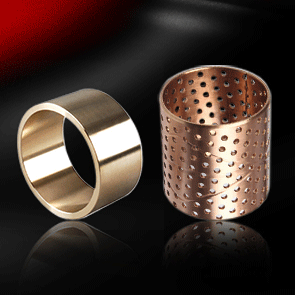

Bronze Bushing Materials: Choosing the Best Type for Your Equipment

In mechanical equipment, the bushing is a crucial component that not only carries the weight of the equipment, but also ensures the normal operation of the equipment in various harsh working environments. Bronze bushings have become the preferred choice in many industries due to their excellent wear resistance and thermal conductivity. However, there are differences in performance among different types of bronze materials. This article will delve into several common materials for bronze bushings to help you choose the most suitable material for your equipment.

Tin Bronze

Tin bronze is one of the most commonly used bronze materials, mainly composed of copper and tin. Due to the addition of tin, tin bronze has good wear resistance, corrosion resistance, and high strength, making it particularly suitable for use in high load and high temperature environments. It is commonly used in the manufacture of bearings, gears, and other high-strength components.

Keywords: tin bronze bush, wear-resistant bronze, corrosion-resistant bush

advantage:

Strong wear resistance: suitable for long-term high load use

Good corrosion resistance: able to withstand most acidic and alkaline environments

High strength: suitable for heavy machinery and high-pressure applications

Lead Bronze

Lead bronze is a bronze alloy with added lead, which has excellent lubricity and wear resistance. The presence of lead makes lead bronze perform well under dry friction conditions, and is therefore commonly used in the manufacture of self-lubricating bearings and other components that require reduced friction.

Keywords: lead bronze bushing, self-lubricating bronze, dry friction bushing

advantage:

Superior self-lubricating performance: suitable for applications without lubrication conditions

Low friction coefficient: reduces energy loss and improves efficiency

Good processability: easy to manufacture and process into complex shapes

Aluminum Bronze

Aluminum bronze is an alloy of copper and aluminum, which is widely used in fields such as marine engineering and chemical equipment due to its excellent mechanical properties and corrosion resistance. Bushing with aluminum bronze has extremely high strength and oxidation resistance, making it suitable for use in harsh environments.

Keywords: aluminum bronze bushing, corrosion-resistant bronze, marine engineering bushing

advantage:

High strength: able to withstand heavy pressure and impact

Excellent corrosion resistance: suitable for marine and chemical environments

Strong antioxidant activity: prolongs service life

Phosphorus Bronze

Phosphobronze is an alloy of copper, tin, and a small amount of phosphorus, known for its excellent elasticity and wear resistance. Phosphorus bronze is commonly used in the manufacture of springs, switch components, and other parts that require high elasticity and wear resistance.

Keywords: phosphor bronze bushing, high elasticity bronze, precision instrument bushing

advantage:

High elasticity: suitable for applications that require resilience

Good wear resistance: suitable for use under long-term friction conditions

Excellent fatigue resistance: prolongs component life

Manganese Bronze

Manganese bronze is composed of copper, manganese, and other elements, and has extremely high strength and corrosion resistance, making it particularly suitable for use in high stress and harsh environments. Bushing with manganese bronze is widely used in the manufacture of ship propellers, pump parts, and other components that require high strength.

Keywords: manganese bronze bushing, high-strength bronze, ship engineering bushing

advantage:

Extremely high strength: suitable for high stress conditions

Good corrosion resistance: suitable for marine and chemical environments

Good resilience: able to withstand impact and vibration

How to choose the most suitable bronze bushing material for you?

When selecting the material of bronze bushing, it is necessary to choose according to the working conditions and usage environment of the equipment. Tin bronze is an ideal choice in high load and high temperature environments; For self-lubricating and dry friction applications, lead bronze is more suitable; Aluminum bronze and manganese bronze are suitable for applications with high strength and corrosion resistance requirements.

When choosing bronze bushings, understanding the characteristics and advantages of different materials can help you better select suitable products and ensure that the equipment can still operate efficiently under the most demanding conditions.

By accurately selecting the material of the bronze bushing, you can not only improve the operating efficiency of the equipment, but also extend its service life and reduce maintenance costs. I hope this article can provide you with valuable reference and help you find the most suitable material for bronze bushing.