What is the Difference Between Bushings and Bearings?

Table of Contents

In mechanical things we use bushings and bearings extensively to reduce friction and to support motion. However, many people get confused and ask, “What is a bushing vs bearing? Are bushings and bearings the same thing?”

Simply put, bushings are a type of bearing. A bushing is also called a plain bearing. Bearings are typically what we think of as roller bearings. However, even though they have similar functions, there are significant differences between a bushing and a bearing including construction, as well as how they function. A bearing is a complete assembly with rolling components, whereas a bushing is a hollow tube. Let’s take a deeper dive into both bushings and bearings, and discover the differences and what type of situations you should use each one.

For more information about how we apply the one or the other, read our related article “Bushings vs Bearings: Application Differences.”

Is a bearing and a bushing the same?

What Are Bushings?

Definition:

Bushings, also known as plain bearings or sleeve bearings, are simple cylindrical components that reduce friction between two sliding or rotating surfaces. They are widely used in machinery due to their straightforward design and versatility.

Structure:

Bushings are typically one-piece, tube-shaped components that fit between a shaft and a housing. Unlike bearings, bushings do not contain rolling elements. Instead, they rely on sliding friction to facilitate motion.

Key Characteristics:

- Designed for low to moderate speeds.

- Simple, low-cost, and often self-lubricating.

- Ideal for heavy-load, static, or oscillating motion applications.

What Are Bearings?

Definition:

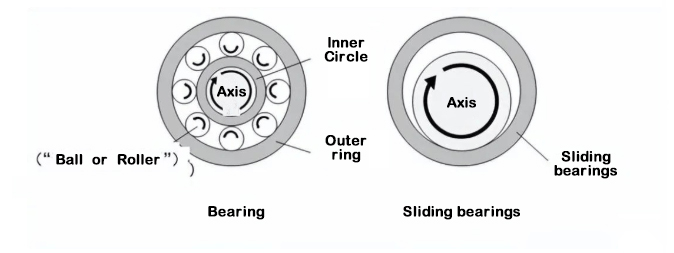

Bearings are precision-engineered mechanical components designed to minimize friction and support motion, particularly in high-speed rotary or linear movements. Unlike bushings, bearings typically incorporate rolling elements to achieve low friction.

Structure:

Bearings are multi-component systems that include:

- Inner Ring: Mounted on the rotating shaft.

- Outer Ring: Fixed within the housing.

- Rolling Elements: Balls, needles, or rollers positioned between the inner and outer rings.

- Cage (Retainer): Keeps rolling elements evenly spaced to ensure smooth operation.

This design reduces contact area, allowing bearings to handle higher speeds with reduced friction compared to bushings.

Key Characteristics:

- Optimized for high-speed and dynamic load applications.

- Require more precise alignment and often need regular lubrication.

- Higher complexity and cost compared to bushings.

What Are the Structural Components of Bearings and Bushings?

Aspect | Bushings | Bearings |

Friction Mechanism | Sliding friction | Rolling friction |

Components | One-piece sleeve | Multi-component (inner ring, outer ring, rolling elements, cage) |

Rolling Elements | None | Balls, rollers, or needles |

Lubrication | Often self-lubricating | Requires lubrication or seals |

Bushings have a simpler design, which makes them easier to install and maintain. Bearings, on the other hand, are more complex due to their precision-engineered components, but they offer superior performance in dynamic, high-speed environments.

Why Don’t Bushings Have Rolling Elements?

One of the biggest differences between bushings and bearings is if the component has rolling elements. A bushing does not have rolling elements because it is simple and serves the purpose where you need some stuff to slide.

Without rolling elements:Are less expensive to make.

- Work better under heavy loads because you have more area where the bushing contacts the surface to carry that load.

- May be designed to be more durable because there are no moving parts.

- Require less maintenance and are often self-lubricating. They don’t need a whole lot of love to keep working.

However, because of their simple design, bushings are not as efficient as bearings in high-speed or high-precision applications, where rolling elements are needed to reduce friction and prevent overheating.

What Materials Are Used to Make Bushings and Bearings?

Both bushings and bearings are available in a wide range of materials, chosen to optimize performance in different conditions:

How Do Bushings and Bearings Work?

The most significant difference in how bushings and bearings work is the type of friction they use:

- Bushings use sliding friction where the shaft comes in contact with the bushing material. Typically you lubricate the bushing with oil or use a self-lubricating material to keep the bushing from wearing out, getting killed, and sucking up all your energy in the form of heat.

- Bearings use rolling friction. The rolling pieces (balls or rollers) never come into direct contact with the shaft or the housing. This type of friction decreases the resistance between the two parts which, in turn, lets a bearing work more efficiently and faster than a bushing.

How Are Bushings and Bearings Installed Differently?

- Typically press-fitted into a housing or shaft.

- Do not require precise alignment, making installation straightforward.

- Self-lubricating bushings often eliminate the need for external lubrication.

- Require precise alignment during installation to avoid uneven load distribution.

- May involve preloading or fitting additional seals and lubricants.

- Incorrect installation can lead to premature wear or failure.