What is a Bronze Bushing?

Table of Contents

A bronze bushing is a type of bearing used to reduce friction and wear between moving parts. These bushings are typically made from a durable bronze alloy, which is a mixture of copper and tin, and sometimes includes small amounts of other metals like aluminum. Bronze bushings are commonly used in a wide range of applications, including automotive, machinery, construction, and agricultural equipment.

In this article, we’ll dive into everything you need to know about bronze bushings—exploring their benefits, lubrication needs, and alternatives.

For more information about how we apply the one or the other, read our related article “Bushings vs Bearings: Application Differences.”

What is a Bronze Bushing?

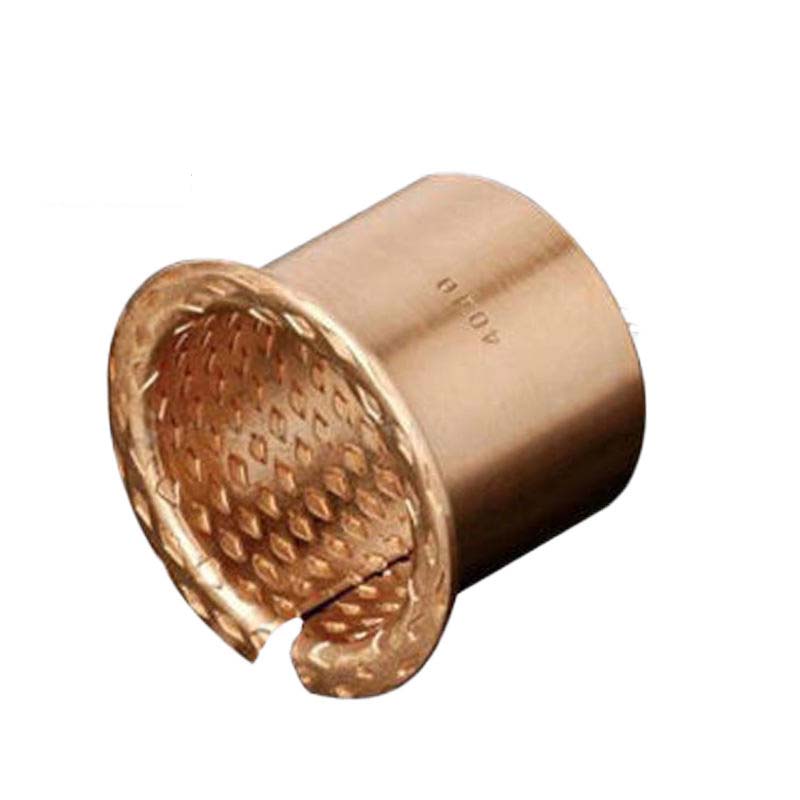

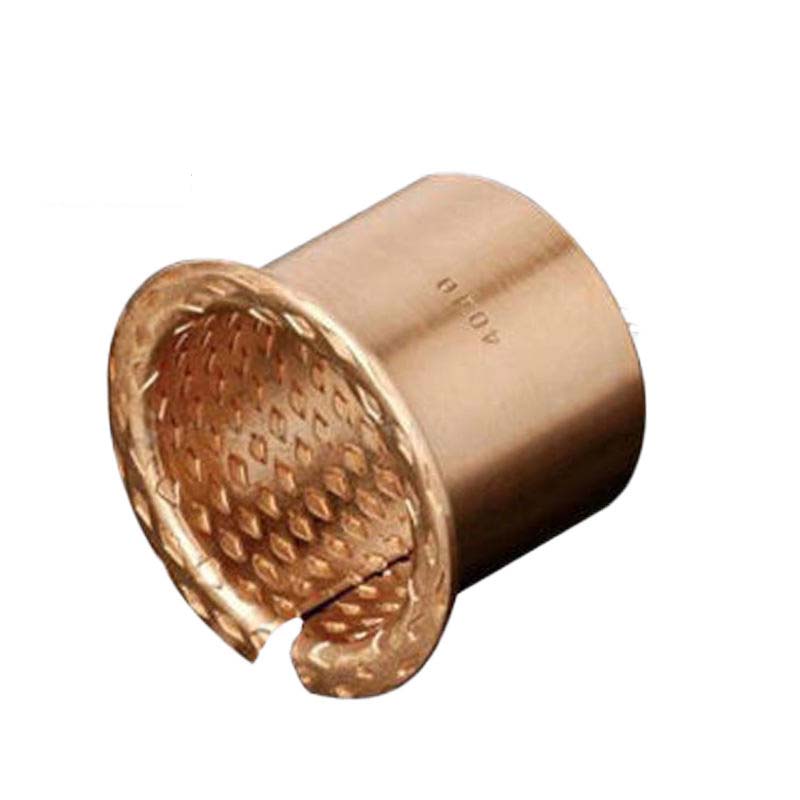

Bronze rolled bearings are usually comprised of copper based alloys like tin bronze (ZCuSn10Pb1, ZCuSn10Pb5, ZCuPb10Sn10, ZCuPb15Sn8, etc.) or zinc copper alloy (ZCuZn38Mn2Pb2) material, which have different characteristics and are suitable for working under different conditions. To be precise, you first roll the copper plate, and then you form the bushing to accomplish your design dimensions and shape

Why Choose Bronze Bushings?

If you’re wondering if bronze bushings are a good solution to support your load, reduce your friction and make you and everyone else happy, the answer is a resounding yes! This material works well. In many cases, it’s probably better than what you have if wear resistance, load capacity, and low maintenance are critical.

Are Bronze Bushings Self-Lubricating?

Bronze bushings offer several key advantages, making them an excellent choice for various mechanical applications:

Durability and Strength: Bronze is super tough, which makes bronze bushings great in high-wear situations where the metal parts are moving against each other all the time.

Corrosion Resistance: Unlike steel parts, bronze doesn’t rust. This is especially important in situations involving water, moisture, or chemicals that can cause other parts to rust and cease functioning.

High Load Capacity: Bronze bushings are able to carry a really heavy load. This means they work great in construction machinery, farm equipment, and lots of different industrial applications.

Low Friction: Bronze has naturally low friction, which helps reduce wear and prolongs the lifespan of both the bushing and the components it interacts with.

Easy Maintenance: Since bronze bushings are durable and require minimal upkeep, they help reduce downtime and maintenance costs in machinery and equipment.

Do Bronze Bushings Need to Be Greased?

Bronze bushings do a decent job without lubrication. Sometimes you want to lubricate your bronze bushings, especially under heavy load and high speed. Here’s why:

- Improved Performance!

- Extended Lifespan!

- Types of Lubrication

Common Types of Bronze Bushings

There are several types of bronze bushings, each suited for specific applications:

1. Plain bronze bushings are just a straight bushing that you may use for a lot of different industrial type applications.

2. Flanged bronze bushings have a flange. Use them where you also have axial loads, and you want the flange to help keep your axial loads from dropping out the sides.

3. Oil-impregnated bronze bushings are literally infused with oil at the time they are manufactured. So you don’t have to grease or oil these little rascals. They have lubricant in them and will last forever.

4. Graphite-plugged bronze bushings have graphite plugs that are supposed to help the bushing consumer lubrication.

How to Select the Right Bronze Bushing?

Some bronze bushings are self-lubricating which means that they reduce friction all by themselves. It’s a special compound so that it doesn’t need to be greased or oiled because it has a lubricant built in.

Self-lubricating bushings have several advantages:

No Maintenance: No required maintenance. This is ideal for hard-to-reach locations where you would not be able to lubricate them on a regular basis.

Reduced Friction: They use embedded solid lubricants like graphite or PTFE, and minimal friction between moving parts.

Longer Service Life: Last longer in demanding conditions because they have wear reduction features built into them.

You’ll find these bushings inside your automotive suspension system, conveyor systems, any and all kinds of machinery where you can’t get in and lubricate on a regular basis.

Conclusion: Bronze Bushings

If you are in the market for some high-quality bronze bushings, please look through our page. If you don’t see what you need or your needs are special or unique, by all means, contact us and we’ll be happy to start a conversation.

Optimize Your Machinery Today with Premium Bronze Bushings!

Ready to invest in durable and high-performing components? Contact us now to learn more about our bronze bushings and how they can enhance your machinery’s efficiency.

FAQ

- Are bronze bushings better than steel bushings?

I believe they do! They offer great wear resistance; you don’t need to worry about corrosion (except for a very specific situation); and they’re essentially a self-lubricating bushing. People use them in applications because of these benefits where they wouldn’t be able to use steel bushings before. - What is the lifespan of bronze bushings?

I can’t answer definitively, but I would say that with a great quality bronze bushing installed on a piece of equipment that is properly adjusted, ran, and hasn’t been modified by someone who doesn’t know what they’re doing, you may last for years without needing to replace it. - Can I use any of my bronze bushings and not worry about lubrication?

Yes, you can! Specifically, there are bronze bushings that are lubricated in the manufacturing process to the point where you should never have to add any additional lubricant. Some are oil impregnated or graphite plugged. In general, the answer is yes!