How do self-lubricating bushings work?

Table of Contents

A bushing that is self-lubricating can have a solid lubricant like graphite embedded in the bronze, brass, or steel bushing blank, and as the bushing wears, it gives off its lubrication. There is no need to lubricate that bushing with grease or oil from the outside.

Self-lubricating bushings are great and pay you awesome dividends when you use them! Engineers created these awesome bush bearings that have some kind of lubricating material embedded in them so your bearings and components don’t need outside oil or grease to keep them working. They last a long time and perform well under different operating conditions.

What Are Self-Lubricating Bushings?

A self-lubricating bushing is a means to reduce friction and wear between moving parts. It is a bushing that is built in such a way that it has its own lubrication. You don’t have to lubricate it like I showed you in the previous lesson. It can be made of PTFE, Teflon, graphite, or have oil impregnated into the bronze or brass. Self-lubricating bushings are good in applications where you can’t grease or oil the bushings, or where grease or oil in the bushing is a potential problem, or if you don’t want to or can’t grease or oil the bushings

Do Bushings Need Lubrication?

Do you have to lubricate your bushings? It depends. The reality is if you have the kind I just talked about, you do need to lubricate your bushings because they will have friction between them and the moving part. If you have a self-lubricating bushing, obviously, you don’t need to lubricate it. It uses a Teflon, PTFE, graphite or oil impregnated bronze or brass type of bushing that lubricates as things are moving around. It’s great if you can’t or don’t want to lubricate bushings.

Why Don’t Bushings Have Rolling Elements?

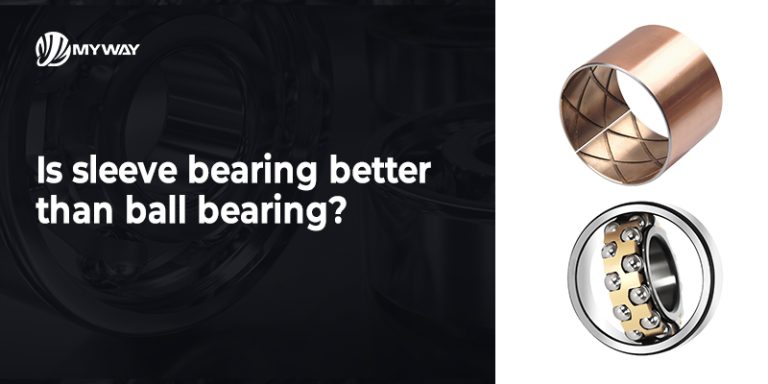

One of the biggest differences between bushings and bearings is if the component has rolling elements. A bushing does not have rolling elements because it is simple and serves the purpose where you need some stuff to slide.

Without rolling elements:Are less expensive to make.

- Work better under heavy loads because you have more area where the bushing contacts the surface to carry that load.

- May be designed to be more durable because there are no moving parts.

- Require less maintenance and are often self-lubricating. They don’t need a whole lot of love to keep working.

However, because of their simple design, bushings are not as efficient as bearings in high-speed or high-precision applications, where rolling elements are needed to reduce friction and prevent overheating.

How Do Self-Lubricating Bushings Work?

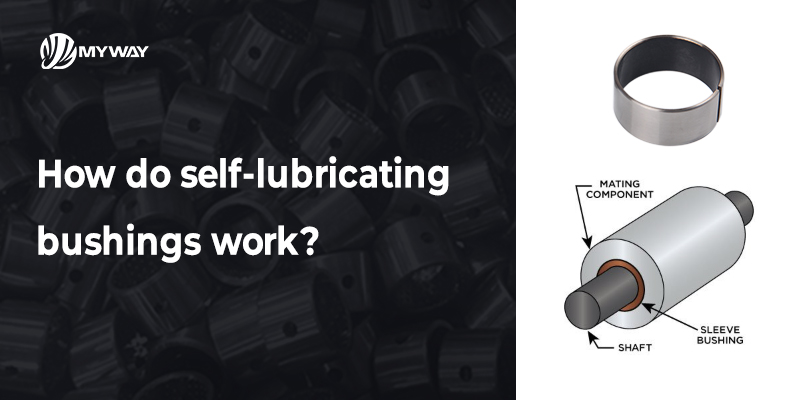

This is how self-lubricating bushings work:

1. Lubrication-Integrated Design

2. Friction Triggers Lubricant Release

3. Self-Healing Surface

4. Material Transfer to Mating Surface

4. Material Transfer to Mating Surface

What Are the Advantages of Self-Lubricating Bushings

What Are the Disadvantages of Bushings?

Why Are Self-Lubricating Bushings Essential?

Conclusion

But obviously, if you can avoid the heat, the maintenance, not have to deal with the lubrication system or the potential of all the problems of lubrication contamination, and everything else by a few bucks you can spend on self-lubricating bushes, then maybe your machinery will perform better for you and cost you less in the long run.

If you are looking for a source for quality self-lubricating bushings like SF1, like SF2, like graphite filled bushings or whatever, then check out the product line on our website. And as always, let us know how we can help you!