What Is the Difference Between Plain Bearings and Bushings?

Table of Contents

Knowing those two words [bushing, and plain bearing], and knowing their definition, what they do, when to use them, and the benefits and advantages they can provide to you on your machine will allow you to save money and increase the efficiency and productivity of your machines.

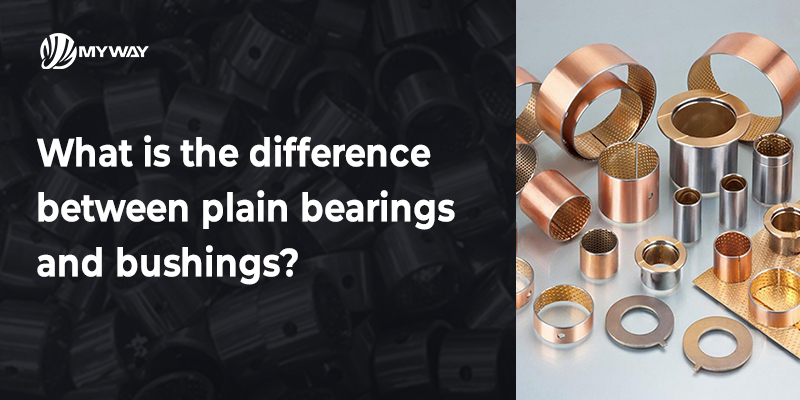

Plain bearings and bushings serve to reduce friction. But a “plain bearing” is a general term for any bearing that doesn’t have rolling elements. On the other hand, a “bushing” is usually a specific type of plain bearing, often in the form of a sleeve used to support and protect the contact between a shaft and its housing.

What Are Plain Bearings?

Plain bearings are parts that are used to support and control moving motion between two parts while reducing friction. They are one of the simplest types of bearings since they don’t have any moving elements like balls or rollers.Usually they’re some solid thing in a certain shape often a cylinder or a sleeve that makes a nice contact for the surfaces to slide against.

What Are Bushings?

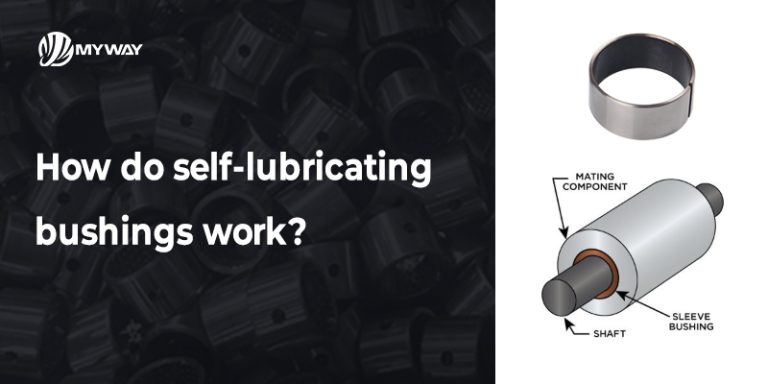

A bushing is a type of plain bearing. It’s a cylinder designed to reduce friction between two moving parts. For example, you have a shaft turning in a housing. Usually you use a bushing to support radial loads. A bushing is often a type of lining or sleeve inside a mechanical system.”

Key Differences Between Plain Bearings and Bushings

Bushings are a type of plain bearing, but there are some differences to keep in mind.

Aspect | Plain Bearings | Bushings |

Definition | A general term for a bearing with no rolling elements. | A specific type of plain bearing, typically cylindrical or sleeve-shaped. |

Design | Includes various shapes like flat surfaces, spherical bearings, or liners. | Always cylindrical or tubular, designed to fit shafts or housing. |

Applications | Broader range, including sliding surfaces, pivot points, and liners. | Primarily used for radial support in rotating or sliding systems. |

Materials | Includes metal, plastic, composite, or even wood. | Typically metal (bronze, steel), plastic, or composite materials with focus on self-lubrication. |

Functionality | Reduces friction and supports motion. | Acts as a sleeve or liner to protect components and reduce wear. |

Advantages of Bushings

Advantages of Plain Bearings

Plain bearings are versatile and offer several benefits in mechanical systems:

How to Choose Between Plain Bearings and Bushings