Do brass Bushings Need Lubrication? A Guide for Industrial Buyers

Table of Contents

Do Brass Bushings Need Lubrication?

Basically, brass bushings require some sort of lubricant to keep them from wearing down and burning up.

Do I need to lubricate brass bushings when you are considering those for your machinery and equipment? That’s the question we’re going to address related to brass bushings today. If you are an industrial buyer, distributor, or parts supplier to the machinery business, one of the things you need to know is how lubrication works with brass bushings, and more importantly, which ones to use or recommend. Let’s dive into it.

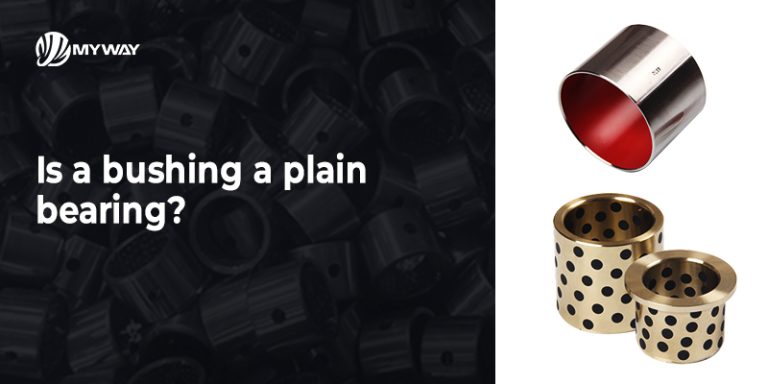

What Are brass Bushings and How Are They Used?

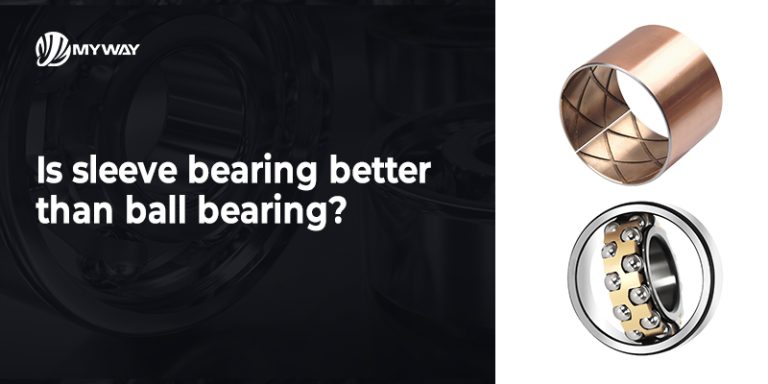

Experts use brass bushings for the superior wear resistance, corrosion resistance, and the low amount of friction they deliver. This is a standard item used in products sold to the industrial and consumer market. It is used in a variety of applications in the construction, agriculture, and automotive industry where metal components need to stand up to heavy loads and harsh conditions on the jobsite.

What sets these brass bushings apart?

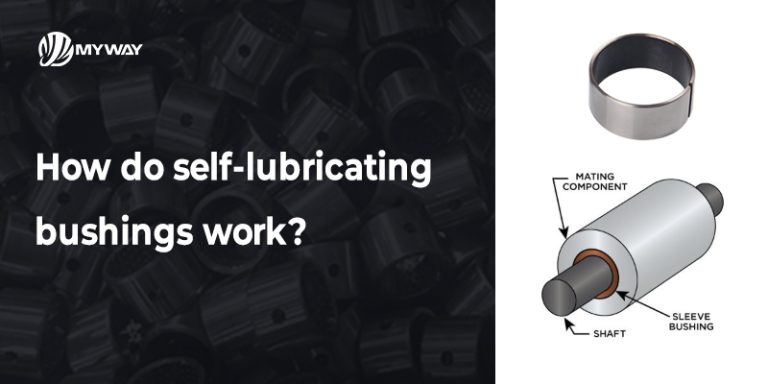

A brass bushing acts as a bearing surface between two pieces where there is movement. Solid brass does lessen friction. Friction plays a role when you have two pieces working against each other. However, brass is a softer material that wears quicker. Watch the video to find out how.

Why Do brass Bushings Need Lubrication?

What is the Best Lubricant for brass Bushings?

Selecting the right lubricant for brass bushings is crucial for their performance and longevity. The lubricant that is best for your application depends on your specific circumstances. Here are a few different types you can use.

Grease:

It’s used in continuously lubricated situations, and it has excellent wear protection for those machines and keeps things running smoothly, which is beneficial for things with moderate loading and at lower speeds.

People going to use lithium grease a lot more.

Oil:

When you need high speed or heavy duty use, then you should use oil. It’s always reaching out a new coat of oil to cool the bushing and to make sure there’s oil between the bush and the shaft. Oil is easy to replenish or replace when you do your regular maintenance.

Solid Lubricants:

In extreme situations where your bushings are in an environment with extreme pressure or heat, use a solid lubricant like graphite or molybdenum disulfide. This is applied to the bushing, and you won’t have to replace it as often. It provides that nice, long-term lubrication.

You can refer to our lubricant article for a more technical understanding of the lubricants that are used in bushing applications.“What is the best lubricant for bushings?”

Can brass Bushings Operate Without Lubrication?

Brass bushings can be used without lubrication in specialized cases:

Low-Load, Low-Speed Applications:

If you use the bushing for a light-duty job with minimal friction, you might not need to lubricate it. Just think about household appliances and the like. You might use brass bushings for some low-speed mechanisms and never lubricate them.

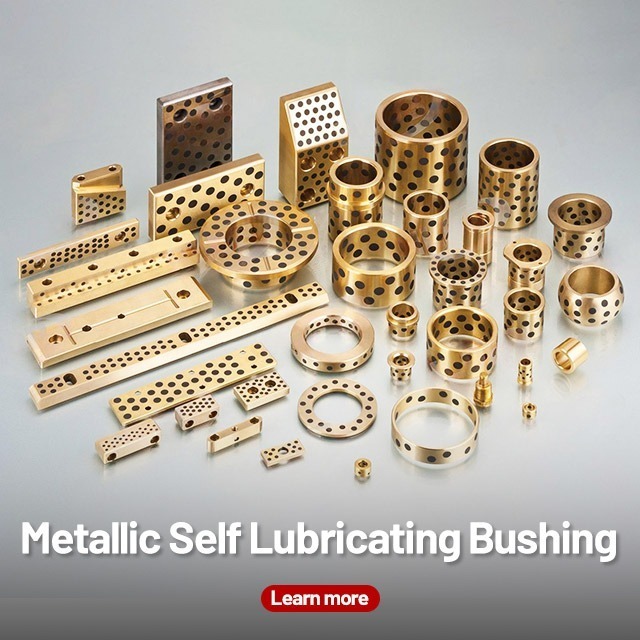

Self-Lubricating Bushings: