Are Bronze Bushings Better Than Brass? A Guide for B2B Buyers

Table of Contents

“A bronze bushing is usually longer-wearing and can handle more load than a brass bushing. A brass bushing is better at standing up to corrosion than a bronze bushing.”

The main reason for this is the composition and structure of the copper alloy. Bronze has tin or other alloying elements giving it better wear, corrosion resistance, and higher strength best suited for heavier loads. Brass, on the other hand, is typically copper and zinc and while it has good corrosion resistance, it doesn’t wear as well, and it is not as strong when you get into higher loads and higher friction.

However, High-Strength Brass Bushing isn’t like regular brass. It has better friction and corrosion resistance and is more suitable for all sorts of heavy-duty construction machinery.

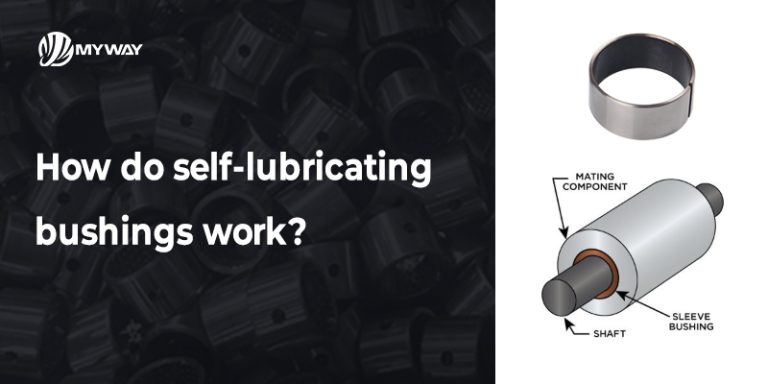

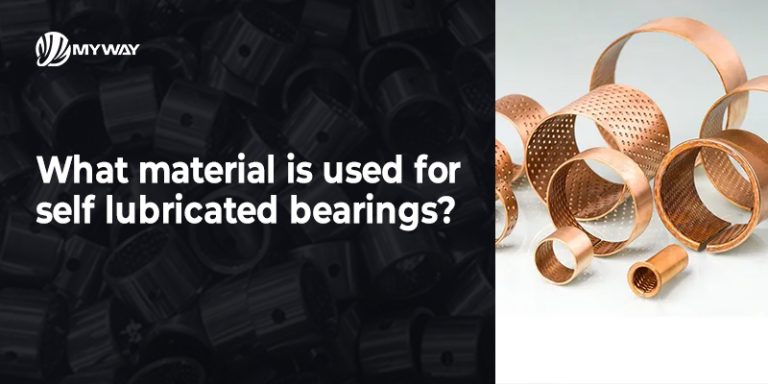

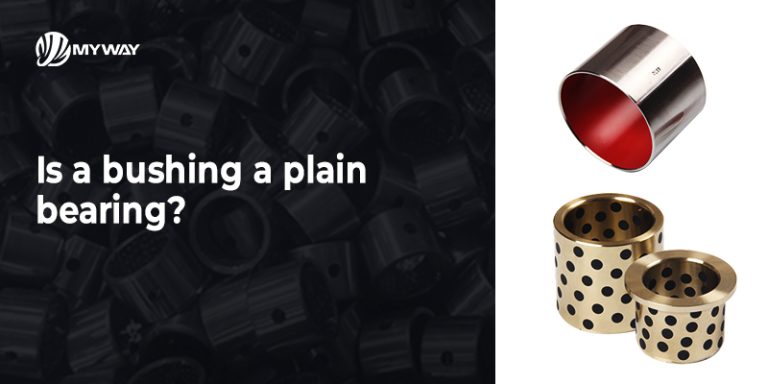

“Or, you can find one of the other articles that we talk about bushings.”

What is the Difference Between Bronze and Brass?

Are Bronze Bushings Better Than Brass for Wear Resistance?

Why Are Bronze Bushings More Corrosion-Resistant Than Brass?

Which Material Is Better for Lubrication?

Are Bronze Bushings Stronger Than Brass?

Which Material Is More Cost-Effective?

Which One Should You Choose for Your Application?