Is a Bushing a Bearing? Understanding the Difference for B2B Buyers

Table of Contents

Bearings include bushings, but not just bushings. Bushings are a type of bearing. Let’s learn more about them in detail

What is a Bushing Also Known As?

Depending on what a bushing is doing and how it’s installed, it will have different names. People refer to bushings as all kinds of things, including:

What is a Bushing?

Is a Torn Bushing Bad?

What is a Bearing?

Key Differences Between Bushings and Bearings

1. Structure and Design

2. Friction and Wear Resistance

3. Load Capacity

4. Lubrication

5. Applications

Why Do You Need a Bushing?

Bushings are crucial components for reducing friction and wear in machinery, and they serve several important purpose:

- Extend the life of the shaft: By providing a wear-resistant surface, you can protect the shaft from direct contact with anything else, reducing the wear and tear on it and extending its life.

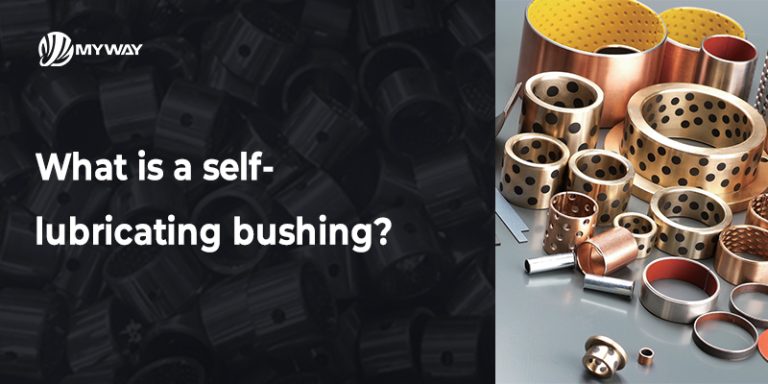

- Minimize maintenance: Especially with self-lubricating bushings, you significantly reduce the amount of maintenance and lubrication you have to do, which is a significant advantage in a lot of harsh environments and applications.

- Reduce operational costs: By avoiding excessive wear you cut down on the cost and the frequency of fixing your equipment to keep it up and running.

- Improve performance: With reduced friction, your equipment performs better in the long run.

For example, you might have heard of SF-1 or SF-2. These are self-lubricating bushings that have a composite structure with a PTFE /Teflon or other type of layer in them to keep them running basically without friction for a long time. We see these frequently used in applications where it’s difficult to maintain oil in a bearing, such as in agricultural machinery, construction equipment, and various automotive parts.

How to Choose the Right Component for Your Needs?

When selecting between bushings and bearings, consider the following factors: