ABOUT MYWAY

Chinese Professional Bushings Manufacturer for Over 20+ Years

Employees: 400

Annual Output Value: RMB 300 Million

Factory Area: 35,000 sqm

MYWAY: Your One-Stop Manufacturer from Raw Material Casting, Sintering to Finished Products

Established in 2005, Zhejiang Myway Co., Ltd. is a national high-tech enterprise specializing in the R&D, production, and sales of bushings, bearings, and related raw materials. With 20 years of dedicated innovation, we have become a leading expert in the bushing manufacturing industry.

Our company operates three modern production bases and a central operations center, spanning over 35,000 square meters in a strategic location in Zhejiang Province with excellent transportation access. We offer end-to-end manufacturing capabilities—from raw material casting and sintering to finished products—supported by over 2,000 precision molds, advanced sintering lines, and state-of-the-art automated equipment and inspection systems, ensuring a highly efficient and reliable supply chain.

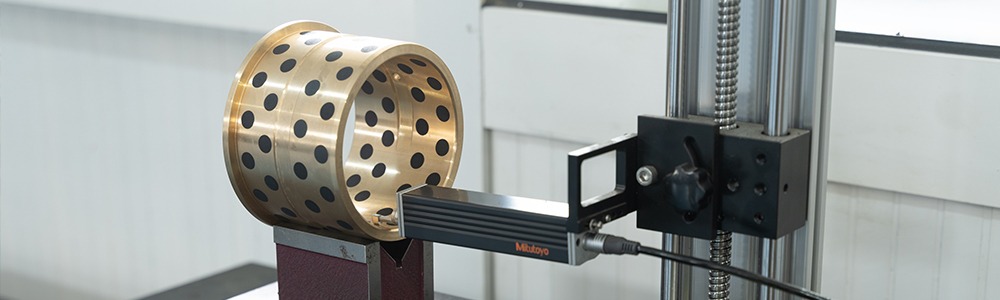

We provide a comprehensive range of plain bearings, including self-lubricating bearings, oil-free bushings, graphite-inlaid copper bushings, bimetallic bearings, and more.

Our products are widely used across various industries such as automotive (passenger vehicles, commercial vehicles, NEVs), construction machinery, agricultural equipment, industrial automation, fluid power, solar and wind energy, steel metallurgy, food machinery, and office equipment. Our products are exported to over 40 countries and regions, including Germany, Italy, Japan, the USA, Canada, and South Korea.

Adhering to the philosophy of “Quality for Survival, Reputation for Development,” we hold multiple international certifications:

ISO 9001:2015

IATF 16949:2016

ISO 14001:2015

GB/T 29490-2013

Backed by a professional R&D team that regularly introduces provincially certified new products, we continuously explore new materials and applications. We are committed to delivering high-quality products and innovative solutions that create real value for our clients. We warmly welcome global customers to reach out for collaboration opportunities.

Our factory

Casting Workshop

Processing Workshop

Inspection Workshop

Finished Goods Warehouse

Factory Gallery

Laboratory Center

Our Cooperated Clients

Certifications & Awards

Our Services

Customization

Materials, dimensions, and designs tailored for perfect compatibility.

Expert Support

Selection advice, installation guidance, and on-site consultation.

Fast Delivery

Reliable supply chain ensures quick turnaround and reduces downtime.

Free Design & Samples

Complimentary design consulting and sample confirmation.

Quality Assurance & Shipping

Rigorous inspection and efficient delivery with full tracking.