Page Structure Overview

Overview of Passenger Car Transmission Bushings

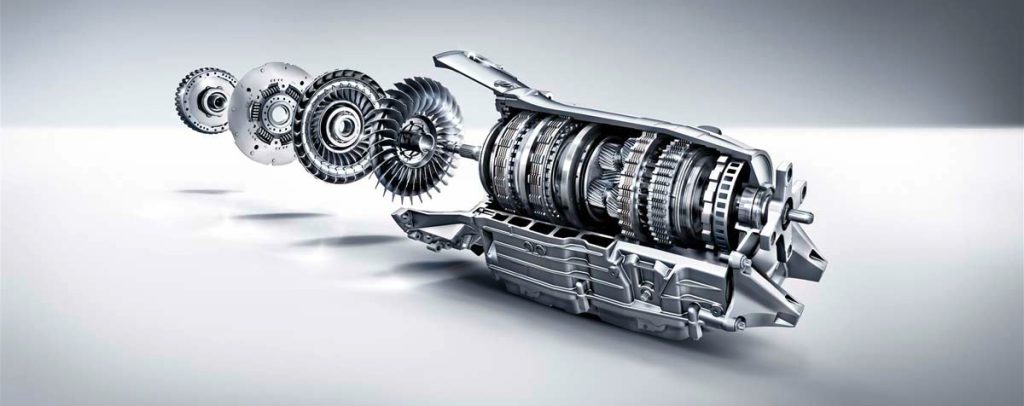

Passenger car transmission bushings are crucial components specifically designed for vehicles such as sedans, SUVs, and MPVs. They reduce friction between parts within the transmission, ensuring smooth and efficient power transfer. Our passenger car transmission bushings use high-wear-resistant, self-lubricating materials, making them ideal for use in manual, automatic, continuously variable (CVT), and dual-clutch (DCT) transmissions.

Application Scenarios for Passenger Car Transmission Bushings

Highlight specific applications within different types of passenger car transmission systems:

- Manual Transmissions (MT): Bushings are used to support the shifting mechanism and synchronizer hubs, ensuring smooth and reliable shifting, suitable for small cars and sports sedans.

- Automatic Transmissions (AT): Bushings provide critical support and lubrication within the torque converter and planetary gear assemblies, suited for family cars and luxury vehicles in high-temperature environments.

- Continuously Variable Transmissions (CVT): Bushings reduce friction and noise in the pulley shaft and transmission mechanism, improving fuel efficiency, suitable for hybrid vehicles and compact SUVs.

- Dual-Clutch Transmissions (DCT): Bushings minimize friction in the dual-clutch system, enhancing shifting speed and smoothness, commonly used in high-performance cars and sports vehicles.

Applicable Vehicle Models

Our transmission bushings are suitable for various types of passenger cars, including but not limited to:

City Sedans: Focused on comfort and fuel efficiency, these models benefit from SF-1 or SF-2 light self-lubricating bushings, ensuring smooth shifting and quiet operation.

SUVs and Off-Road Vehicles: Designed to handle higher loads and complex road conditions, we recommend bimetallic or embedded graphite bushings for exceptional durability and reliability.

High-Performance Sports Cars: With a focus on speed and handling, these vehicles require greater stability and wear resistance, making embedded graphite bushings the optimal choice.

Materials & Technology of Gearbox Bushings

Our transmission bushings are made from various high-performance materials to meet the demands of different car models and challenging driving environments:

SF-1/DU Self-Lubricating Bushings: Made from a multi-layer composite material that includes a steel backing, a bronze powder layer, and a PTFE (Polytetrafluoroethylene) surface coating. These bushings perform exceptionally well in high-temperature and heavy-load conditions, reducing wear and noise while extending the transmission’s service life.

SF-2/DX Bushings: Also featuring self-lubricating properties, these bushings are designed to work well with external lubricants, making them ideal for semi-dry operation environments and higher load scenarios.

Bimetallic Bushings: Composed of a steel base combined with a copper alloy, these bushings offer excellent load capacity and outstanding wear resistance, making them well-suited for transmission systems that need to withstand higher loads, especially common in SUVs and off-road vehicles.

Embedded Graphite Bushings: These bushings have solid lubricants like graphite or MoS2 embedded in the copper alloy surface. They maintain low friction and self-lubricating characteristics under extreme conditions, making them ideal for sports car transmissions that require high stability at heavy loads or high speeds.

Product Range and Detailed Specifications

Offer detailed models, materials, and performance parameters for passenger car transmission bushings, enabling B2B buyers to make precise choices. For example:

Partial gearbox bushings

| Product Model | Inner Diameter Range | Outer Diameter Range | Length Range | Material Type | Applicable Transmission Type | Max Load (MPa) | Temperature Range (°C) |

| CVT-BS01 | 10-50 mm | 12-60 mm | 15-80 mm | PTFE Composite | CVT | 100 | -40~200 |

| AT-BS02 | 12-60 mm | 15-70 mm | 20-90 mm | High-Strength Brass | Automatic | 120 | -40~250 |

| DCT-BS03 | 15-70 mm | 18-80 mm | 20-100 mm | Bronze Composite | DCT | 140 | -30~280 |

| Application/Description | Years | Material | OEM # | Industry | MW # |

| Chrysler | |||||

| A404, A413, A470, A670 | |||||

| A413, A470, A670 Center Support, Front | 85-on | Babbitt | MD731163A | 42005 | 28334 |

| A413, A470, A670, A604, 40TE, 41TE, 41AE, A904,TF6, A500, 44RE, 40RH, 42RH, 44RH, A500, 42RE Pump Body | 68-on | Bronze | 2466796 | 12502A | 33382 |

| A404, A413, A470, A670 Extension Housing | 78-on | Bronze | 4269961 | 32060 | 33390 |

| A404, A413, A470, A670 Low, Reverse Drum | 78-on | Bronze | 5222137 | 32040 | 33391 |

| Ford | |||||

| 6R140, 6R60E, 6R75, 6R80 | |||||

| 6R140 Pump Stator | 10-on | Babbitt | TBA | TBA | 316311 |

| 6R80 Pump | 06-on | PTFE | E8SP-7A132AA | 96005 | 31831X |

| 6R60E, 6R75, 6R80 Stator Tube, Rear (1.180”ID) | 05-on | Babbitt | 1006-614 | N/A | 31833B |

| General Motors | |||||

| ALLISON 1000, 2000 | |||||

| ALLISON 1000, 2000, 2400 PUMP | 411311 | ||||

| 3T40, TH125 Stator Support, Front | 80-on | Babbitt | 8628915 | 65002 | 33317 |

| 3T40, TH125 Case To Final Drive Gear | 80-on | Bronze | 8631119 | 75019 | 33322 |

Learn more about gearbox bushings

If you want to find more information about the size, material or OEM number of transmission bushings, you can contact us. We have a lot of cooperation with transmission merchants in the Middle East

Product Advantages (Specific to Passenger Cars)

- Improved Driving Smoothness: By reducing friction and noise, the transmission bushings ensure smoother operation of the transmission, leading to a more comfortable driving experience.

- Extended Transmission Lifespan: The use of high-wear-resistant materials reduces wear on critical components, extending the lifespan of the transmission and the overall drivetrain.

- High-Temperature Stability: Designed for high-temperature and high-load conditions, these bushings ensure stability, especially suitable for long-distance and high-speed driving.

- Enhanced Fuel Efficiency: The self-lubricating properties reduce internal energy losses within the transmission system, improving the fuel economy of passenger vehicles.

Our Advantages

Premium Materials: Manufactured with internationally recognized high-performance materials, ensuring bushings with superior wear resistance and high load capacity.

Precision Manufacturing: Using advanced production equipment and strict quality control, we ensure the dimensional accuracy and surface finish of each bushing, reducing friction and noise.

Custom Solutions: We offer customization based on client requirements, with a wide range of specifications and material options to meet the specific needs of different car models and working conditions.

Global Supply Chain: With a broad distribution network, we can quickly respond to customer demands, ensuring timely delivery and supporting your business operations.

Why Choose Our Passenger Car Transmission Bushings?

By choosing us, you’ll receive transmission bushings that offer stable performance and longer service life. We are dedicated to providing high-value products that enhance your competitive edge in the passenger car market. Whether you’re a distributor, repair shop, or auto parts supplier, our products and services can help you achieve business growth and customer satisfaction.

Our Advantages Successful Case Studies

Supply and Quality Assurance

- Large-Scale Production Capacity: We maintain advanced production lines and sufficient inventory, ensuring the ability to fulfill bulk orders and continuous supply for passenger car production.

- Strict Quality Control: Each batch undergoes rigorous quality testing, including wear resistance, temperature tolerance, and dimensional accuracy, to meet industry standards.

- Global Logistics Network: Backed by a well-developed international logistics network, we ensure timely delivery and support for clients worldwide.

CTA (Call to Action)

- “Get a Quote for Passenger Car Transmission Bushings”: Encourage buyers to get bulk pricing, facilitating the sales process.

- “Request Passenger Car Transmission Bushing Samples”: Allow potential clients to request samples, helping them evaluate product performance in actual applications.

- “Contact Us for Technical Consultation”: Invite customers to discuss customization options and technical details with the engineering team.

Custom Services and Solutions

Customization & Support Services

- Multiple Customization Options: Tailor materials, dimensions, and designs to meet specific customer needs, ensuring optimal compatibility.

- Professional Technical Support: Provides selection advice, installation guidance, and on-site technical consultations to help customers optimize performance.

- Fast Delivery: Robust supply chain and logistics services ensure timely delivery, reducing the risk of customer downtime.

Free consultation

Communicate with us to clarify the requirements

Free design

Customize your product according to your needs

Sample making

Confirm the drawings and arrange for sampling

Sample Confirmation

Customer confirms sample and arranges production

Finished inspection

Inspect the finished product and arrange for shipment

FAQ

Are you a factory?

Of course, we are a manufacturer that can complete the entire production line from raw materials to finished bushing products.

What bushings do you production?

We mainly produce various self-lubricating bushings. Please refer to our product solutions or contact us for details

What is a bushing?

What is the general process for manufacturing bushings?

Bushing manufacturing involves several key steps:

Material Selection: Choosing the appropriate material such as bronze, rubber, or plastic, depending on the application.

Forming: Techniques like casting, pressing, or extrusion are used to shape the raw material into a bushing.

Heat Treatment: For metal bushings, heat treatment is applied to increase strength and wear resistance.

Finishing: This step involves precision machining to achieve the required dimensional tolerances and surface finish.

Surface Treatment: A coating may be applied for corrosion resistance or lubrication purposes, such as zinc plating or Teflon coating.

What materials are commonly used in bushing production?

Common materials used in bushings include:

Bronze: Known for its durability and low friction, often used in heavy-duty applications.

Rubber: Used for vibration dampening in automotive and machinery applications.

Nylon/Polymer (like PTFE): Provides self-lubrication and is ideal for low-load, low-friction environments.

Steel: Used for high-load applications, often combined with a softer material like bronze or plastic as the lining.

How are bushing dimensions and tolerances maintained during production?

What surface treatments are used for bushings?

Bushings often undergo surface treatments to enhance their properties:

Zinc or nickel plating: Protects the metal surface from corrosion.

Teflon (PTFE) coatings: Provide low friction and self-lubricating properties.

Phosphating or black oxide coating: Improve wear resistance and reduce the potential for galling (severe adhesion between surfaces in motion).

What are the challenges in bushing production?

Key challenges include:

Maintaining precision: Ensuring dimensional accuracy across large production runs can be difficult, especially for complex shapes.

Material selection: Using the wrong material could result in failure under stress or environmental conditions.

Surface finish quality: Achieving smooth surface finishes is crucial to reducing friction and wear.

Can bushings be custom-made?

What environmental factors are considered in bushing production?

Manufacturers consider several environmental aspects:

Material sustainability: Using eco-friendly or recyclable materials.

Waste management: Minimizing production waste and properly handling hazardous materials.

Energy consumption: Optimizing energy use in production processes to reduce carbon footprint.

What is the purpose of a bushing?

How can I tell when a bushing needs to be replaced?

Signs that a bushing may need replacement include:

Cracks, splits, or visible damage.

Increased noise, such as squeaking or grinding.

Excessive play or movement in the component where the bushing is installed.

Vibration or instability in the machinery or equipment.

How do I maintain bushings?

What is the difference between a bushing and a bearing?

How long do bushings last?

More Related Bushing products

- Suspension System:

- Control arm bushings, stabilizer bar bushings: Typically made from polyurethane or polyoxymethylene (POM) due to their wear resistance and good frictional properties, suitable for enduring repetitive friction and load.

- Shock absorber top mount bushings: Likely made from polyurethane or silicone rubber, to absorb vibrations and reduce noise.

- Steering System:

- Steering knuckle ball joint bushings, tie rod end bushings: Polyterafluoroethylene (PTFE) or polyoxymethylene (POM) are common in these locations for their very low friction coefficient and high wear resistance.

- Steering column bushings: Polyterafluoroethylene (PTFE) or polyimide (PI), providing smooth steering operations and high-temperature resistance.

- Transmission:

- Transmission bearing bushings, selector rod bushings, output shaft bushings: Often use bronze-filled PTFE or polyimide (PI) due to their ability to withstand high temperatures and complex mechanical stresses.

- Engine Components:

- Piston pin bushings, connecting rod bushings, crankshaft main bearing bushings: Commonly use bronze or fiber-reinforced PTFE to endure extreme thermal loads and friction.

- Drivetrain:

- Clutch actuator arm bushings, driveshaft center support bushings: Made from polyurethane or polyoxymethylene (POM), providing durability and vibration reduction.

- Brake System:

- Brake pedal pivot bushings, handbrake linkage bushings: Polyurethane or polyterafluoroethylene (PTFE) to optimize smooth operation and durability.

- Body Components:

- Door hinge bushings, trunk hinge bushings: Typically made from polyurethane or silicone rubber, for their wear resistance and damping properties.

- Interior Functional Components:

- Seat rail bushings, steering wheel adjustment mechanism bushings: Polyterafluoroethylene (PTFE) or polyurethane, offering smooth adjustment functions and wear resistance.

- Air Conditioning and Cooling Systems:

- Fan bracket bushings, adjustment valve bushings: Polyimide (PI) or polyterafluoroethylene (PTFE), chosen for their high temperature resistance and chemical stability.

Contact Us for More Information

We not only provide high-quality self-lubricating bushings but also offer comprehensive technical support and after-sales service to ensure your equipment always operates at peak performance. If you have any questions or need a quote, please feel free to contact us at any time.

Tel/Whatsapp: +86 136 4583 4002

Email:ivan@mybushing.com