What is the Most Durable Bushing?

Product Solutions Close Product Solutions Open Product …

Product Solutions Close Product Solutions Open Product …

Product Solutions Close Product Solutions Open Product …

Flanged sleeve bearings work well for many applications. They’re easy to install and provide superior results when it comes to carrying a load. Use them to solve a difficult manufacturing problem and you’ll be a hero. Understanding the differences between flanged sleeve bearings and the other types of bearings in the market helps you make the right choice for your machine’s specific needs.

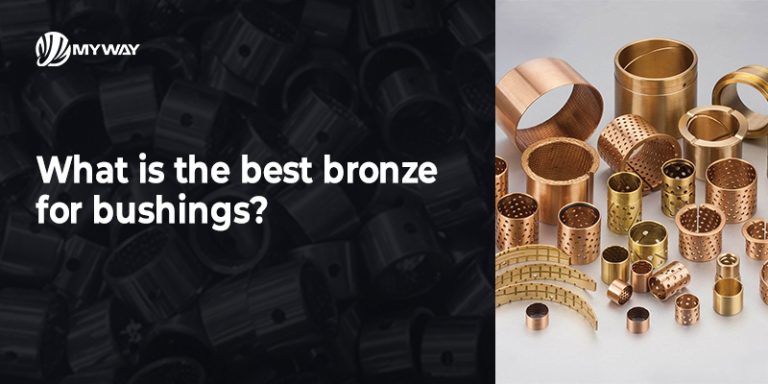

For high wear and load, use phosphor or beryllium bronze. For corrosion resistance in marine/offshore, choose aluminum bronze. Tin bronze is a cost-effective option for wear and anti-friction.

Oil-impregnated bronze bushings are durable, low-maintenance, and corrosion-resistant, ideal for high-load, wear-resistant, and low-friction applications in various industries.

Product Solutions Close Product Solutions Open Product …

Bronze bushings that aren’t self-lubricating need putting grease or oil, but they also have a kind that is self-lubricating, where there are embedments of lubrication like graphite or PTFE.

You need to lubricate your brass bushings to keep them from sticking, prevent them from heating up, and keep them from wearing out. A good lubrication practice helps your brass bushings last a long time. Choose the right lubrication for your brass bushings, or it will cost you in maintenance and downtime for the machinery in which you use them.

Product Solutions Close Product Solutions Open Product …

– For high load, high temperatures, and heavy duty, consider bronze and steel.

– For corrosion resistance and heat conduction, copper is great.

– For self-lubricating and low maintenance, consider composites like PTFE or PEEK, or Nylon.

– For shock absorption and durability, nothing beats polyurethane.

MYWAY has been a company dedicated to manufacturing high-precision, low-noise bushings for 20 years

Precision Bushings Driving a World in Motion——Every Turn, Every Time

Site Directory

Hello, welcome to my website. We have a wide range of lining products and comprehensive services. Is there anything I can help with?

Do you have any questions about casing or myway?

WhatsApp Us

🟢在线|隐私政策

WhatsApp us

Consult us now