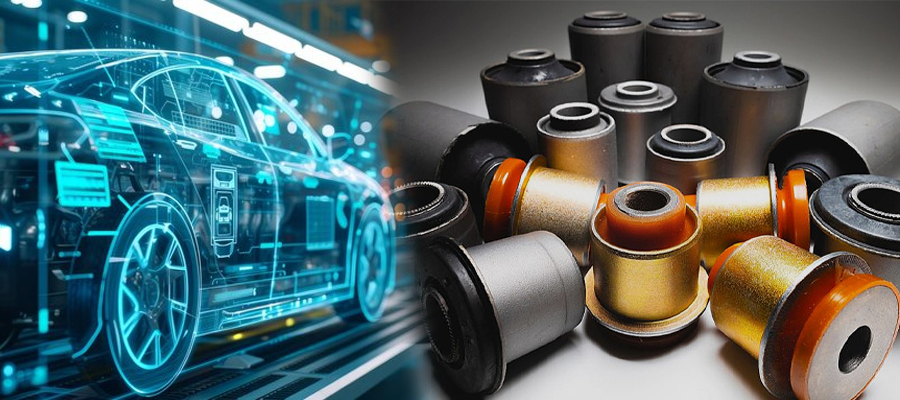

What are Bushings in a Car?

Have you ever heard a “clang” noise coming from the chassis on a bumpy road? Or found that the steering wheel has become loose and the tires have abnormal wear? These seemingly unrelated phenomena may all point to the same “culprit” – car bushings.

Bushings are widely used in cars and are installed between various metal parts to prevent friction, reduce noise and buffer. It greatly reduces the frequency of replacement of car parts and makes the car more stable during driving.

This blog mainly discusses which parts of the car need bushings, what are the commonly used types of bushings, and how to choose the most suitable bushings for your car. Keep reading and many of your doubts will be answered.

Table of Contents

1. How Important are Bushings on a Car?

What are car bushings and what role do they play in a car? After reading this part, I am sure you will have a comprehensive understanding of the importance of bushings in automobiles.

1.1 What are Car Bushings?

Car bushings are key components specifically designed for use in automotive suspension and steering systems. They are installed at the interface between the 2 components to dampen vibration, absorb noise, and control the relative motion between the components to reduce friction. As a result, they can effectively extend the service life of automotive parts and maintain ride comfort and handling stability.

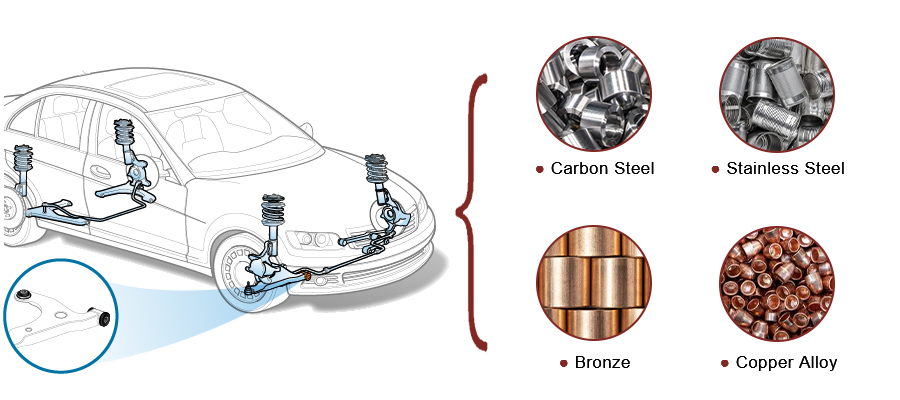

Usually made of metal, including carbon steel, stainless steel, bronze, copper alloy, etc., car bushings have high mechanical strength and wear resistance. They are usually straight or flanged, with diameters of 2-10 cm and load capacities of up to 40-130 N/mm².

1.2 What Do Car Bushings Do?

The role of automotive bushings is mainly reflected in 3 aspects:

- Shock Absorption Buffer:In the process of automobile driving, there will inevitably be bumps. Bushings can absorb the impact of the road surface, reduce the probability of direct collision of metal parts, significantly improve ride comfort.

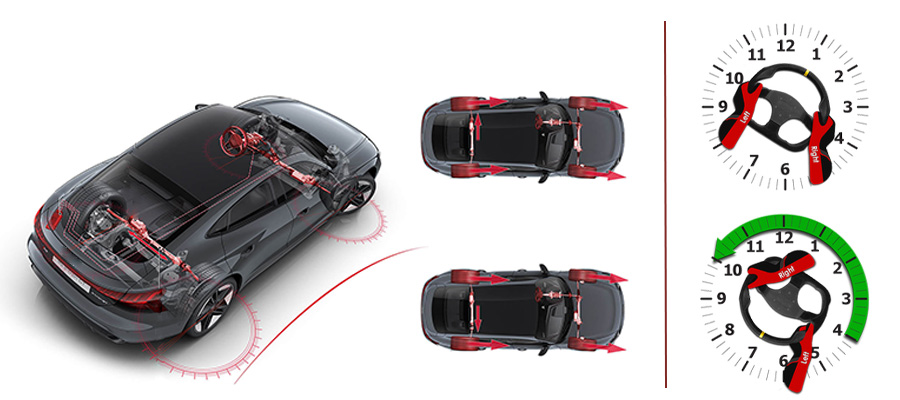

- Noise Reduction and Muffling:The friction coefficient of automotive bushings is very low, they can reduce the noise inside the car by more than 30% by suppressing vibration transmission.

- Stabilizes Handling:Bushings in the steering wheel and joystick maintain suspension geometry and ensure steering precision.

2. Where are the Bushings Located on a Car?

We all know that a car is assembled from 10-30 thousand parts, including the engine, transmission, clutch, chassis,etc., and many of these parts need bushings as articulation. Do you know how many bushings are in a car? This section introduces 8 main parts need bushings.

2.1 Control Arms

The control arm is a strong metal part that connects the frame to the wheel, and the connection needs bushings to act as a cushion.

The control arm bushing is usually made of hard rubber to prevent the control arm from rubbing against other parts as it moves. In addition, it absorbs the impact from ground while the car is moving.

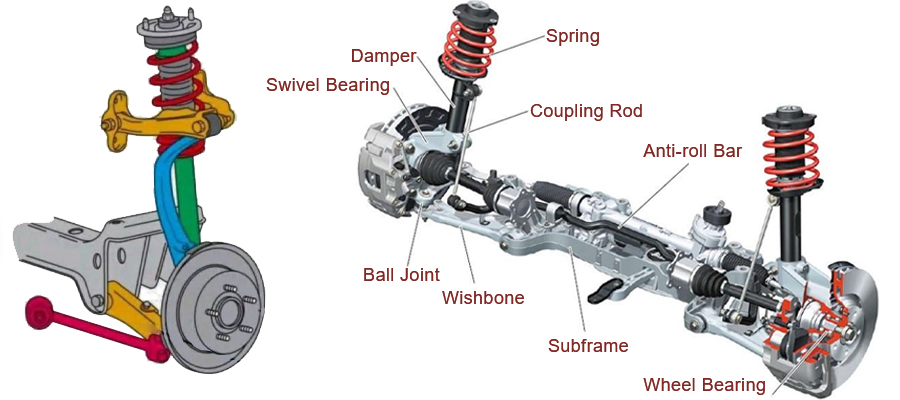

2.2 Suspension Joints

The suspension joint includes upper and lower swing arm joints, steering knuckle connection points, etc., which need to move up and down when working.

Suspension bushes can provide positioning points, allowing the suspension components to move freely while absorbing noise, shock, and vibration. Due to the high friction environment, bushings are typically made of metal housing with silicone or nitrile rubber lining.

2.3 Leaf Spring

The leaf springs are long, slightly curved, flat pieces of steel that are commonly found in commercial vehicles, vintage cars, pickup trucks, etc.

The leaf spring bushings connect the frame and body to the axle, allowing suspension movement by bending and flattening under different driving conditions. They are able to withstand huge torsional and radial loads while not requiring regular lubrication.

2.4 Tie Rods

The tie rod end is located on each front wheel of the car. It is the pivot point between the steering rack, steering arm and steering wheel, ensuring that the steering system can steer normally.

The tie rod bushing is usually composed of a metal frame and elastic material. It is responsible for buffering vibration and friction during the transmission of steering force, ensuring the accuracy and comfort of steering.

2.5 Shock Absorbers

Shock absorbers help improve vehicle handling, absorb high-frequency vibrations from the road, and give passengers a smoother ride. They are connected to the frame through bushings to prevent the spring from repeatedly expanding and contracting after being stressed.

Shock absorber bushings are mainly used to connect shock absorbers to the frame or control arms, absorbing road shocks, reducing vibration transmission, and maintaining precise positioning of suspension components through elastic materials.

2.6 Strut Mounts

The car’s strut mount is located on top of the shock absorber, connecting the shock absorber piston rod to the body and isolating the vehicle from vibration and tire noise. It has a bushing installed inside to absorb high-frequency vibrations and reduce friction resistance.

2.7 Stabiliser Bars

As a U-shaped metal rod, the two ends of the car stabilizer bar are connected to the left and right suspensions through connecting rods to suppress the body roll. When the vehicle is turning, the anti-roll bar transfers the compression force of the suspension on one side to the other side through the bushing, greatly reducing the risk of high-speed cornering roll.

2.8 Chassis

Chassis bushings are located at the connection points of control arms, subframes, and trailing arms. Their core function is to connect metal parts and buffer vibrations. Their elastic materials can absorb road impacts and reduce vibrations transmitted into the vehicle. In addition, they can ensure that chassis parts maintain precise angles under dynamic loads to prevent uneven tire wear.

3. 4 Common MYWAY Bushings Used in Cars

Do you know which bushings are most commonly used in automobiles? What are their functions? Keep reading and you will have a deeper understanding.

3.1 Rubber Bushings

Rubber bushings are made of synthetic rubber and natural rubber, including EPDM, silicone rubber, nitrile rubber, silicone, Viton, etc. Their advantages are excellent tensile strength and flexibility, no need for lubrication, and longer service life with less maintenance.

In the automotive industry, rubber bushings are widely used, playing the role of shock absorbers in components such as gear levers, suspension systems, and special internal combustion engines. They can effectively suppress the impact and vibration transmission between components, ensuring driving safety and comfort.

The self-lubricating bushing has 3-layer structure: steel back, sintered bronze powder layer and PTFE lubricating layer. It has self-lubricating properties and does not require any external lubrication, which greatly reduces the maintenance frequency and is suitable for long-term driving of the car.

The self-lubricating bushing in the car is usually installed in the body hinge system, chassis suspension joints and power system. Its friction coefficient in an oil-free environment is as low as 0.05, which can withstand frequent reciprocating motion and reduce noise.

The bimetal bushing is supported by a low-carbon steel backing and copper alloy or aluminum alloy, including CuSn10Pb10, CuSn4Pb24 and AlSn20. Its metal composite structure makes it suitable for high-load, low-speed scenarios.

The engine, gearbox, suspension system and other parts of the car are in a high-temperature and high-pressure environment, and bimetallic bushings are required as lubrication without causing damage to them. The bushing can withstand a static load of 150N/mm² and maintain stable lubrication for a long time.

Bronze bushings include pure bronze bushings, high-strength brass bushings, sintered bronze composite bushings, special bronze alloy bushings, etc. It has natural anti-friction and corrosion resistance, and its tensile strength is greater than 600MPa.

Phosphor bronze (CuSn8) bushings and aluminum bronze (CuAl10Fe3) bushings are used for automobile water pump shafts, air conditioning compressor main shafts, suspension swing arm shafts, etc. Their hardness is HB80-100, which can withstand off-road impacts and resist mud and water erosion.

4. Conclusion

This blog introduces various bushings used in cars. If you are a car enthusiast or driver, you must hope that the bumps and noise can be reduced during driving, and the steering wheel is very precise when turning. Bushings can perfectly meet your various needs, improve your driving quality, tire life, and even driving safety!

If you plan to buy high-performance and high-quality bushings for your car, then Myway bushings must be your best choice. We specialize in designing and producing various bushings, whether it is rubber bushings, self-lubricating bushings, or metal bushings, etc., providing you with one-stop shopping services. If you are interested, Click Here to start our cooperation.

100000+ Types of Bushings – Contact Us for Details