What is a Bimetal Bushing?

Bimetal bushings are a type of composite bearing made from two distinct layers of metal: a steel backing for structural strength and a sintered bronze or copper alloy layer for excellent wear resistance and lubrication retention. This combination provides an ideal solution for applications requiring high load-bearing capacity, low friction, and superior durability.

Table Of Contents For This Page

To make sure you can find the information you want quickly,

we have prepared this content directory that will jump to the corresponding location when you click on it.

Bushing Material

Material Composition and Structure

Bimetal bushings are constructed using a two-layer metal structure to maximize both strength and wear resistance:

The outer layer of the bushing is made of high-quality steel, providing the foundation for high load-bearing capacity and resistance to mechanical stress. This layer ensures the bushing maintains its form and structural integrity under high pressure.

Material Combination

| Material Type | MW-3(800) | MW-3(720) | MW-3(700) | MW-3(20) | MW-3(930) | MW-3(870) | MW-3(910) |

| Bronze | CuPb10Sn10 | CuPb2Sn4 | CuPb30 | AlSn20Cu | CuSn6.5P0.1 | CuSn10Bi3 | CuSn8Ni1 |

| Equivalent Code | SAE-797 GLYCO66 JIS-LBC3 | SAE-799 GLYCO668 JIS-LBC6 | SAE-48 JIS-KJ3 | SAE-783 GLYCO74 JIS-ALJ | SAE-797 GLYCO66 JIS-LBC3 | SAE-797 GLYCO66 JIS-LBC3 | |

| Metallographies | | ||||||

| Hardness of Bronze alloy HB | 70-100 | 45-70 | 30-45 | 30-40 | 60-90 | HB70-100 | HB60-90 |

| Allowable Max Dynamic Load N/mm² | 65 | 38 | 25 | 30 | 65 | 80 | 80 |

| Hardness of mating surface | 53HRC | 50HRC | 270HB | 250HB | 50HRC | 53HRC | 53HRC |

| Max.Temperature ℃ | 260 | 200 | 170 | 150 | 200 | 260 | 260 |

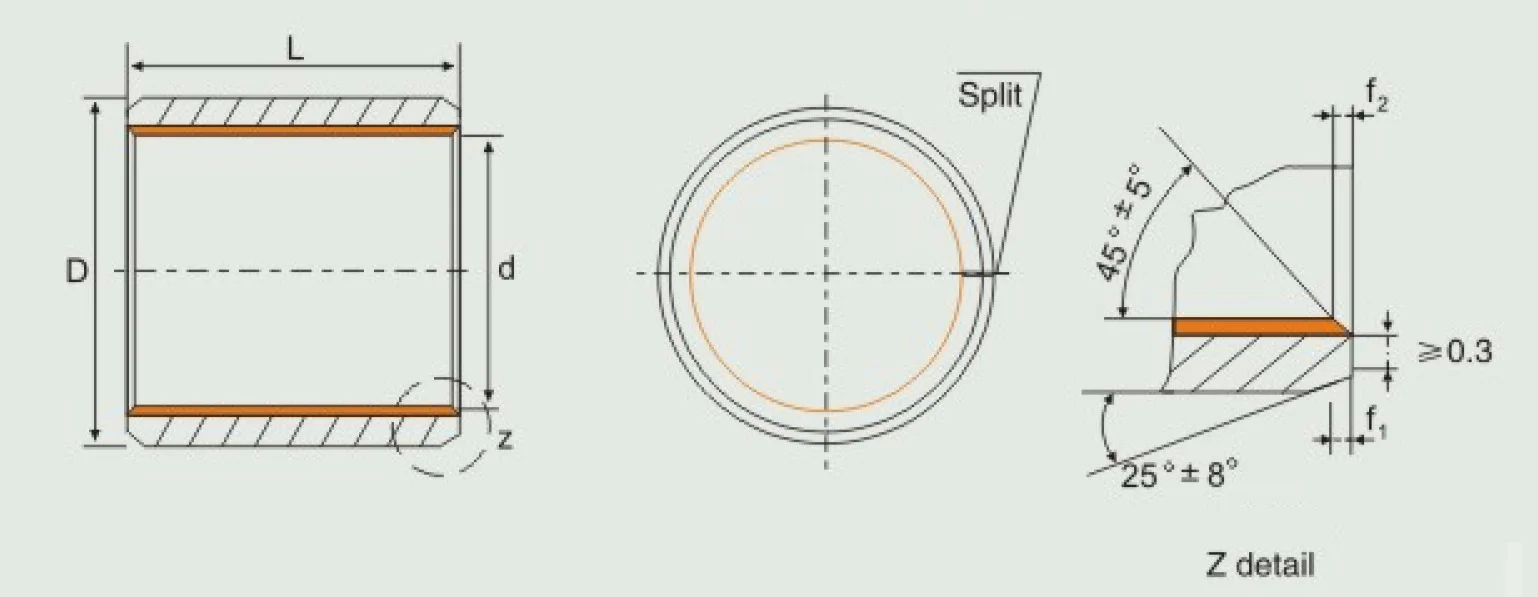

Bushing Size

| d | D | Wa Thicknes | 0.D | 1D | Housing Bore | Jouma Diamele | f | f | L 040 | |||||||||

| 10 | 15 | 20 | 25 | 30 | 40 | 50 | ||||||||||||

| 10 | 12 | 1-0.025 | 12 | +0.065 +0.030 | 10 | +0.022 +0.000 | +0.018 12 | 10 | -0.013 -0.028 | 0.5 | 0.3 | △ | △ | △ | ||||

| 12 | 14 | 14 | +0.065 +0.030 | 12 | +0.027 40.000 | +0.018 14 | -0.016 12 -0.034 | 0.5 | 0.3 | △ | △ | △ | ||||||

| 14 | 16 | 16 | +0.065 +0.030 | 14 | +0.027 +0.000 | +0.018 16 | 14 | -0.016 -0.034 | 0.5 | 0.3 | △ | △ | △ | |||||

| 15 | 17 | +0.065 17 +0.030 | +0.027 15 +0.000 | +0.018 17 | 15 | -0.016 -0.034 | 0.5 | 0.3 | △ | △ | △ | |||||||

| 16 | 18 | +0.075 18 +0.035 | +0.027 16 +0.000 | +0.018 18 | -0.016 16 -0.034 | 0.8 | 0.4 | △ | △ | △ | ||||||||

| 18 | 20 | 20 | +0.075 +0.035 | +0.033 18 +0.000 | +0.021 20 | 18 | -0.016 -0.034 | 0.8 | 0.4 | △ | △ | △ | △ | |||||

| 20 | 23 | 1.5-0.03 | +0.075 23 +0.035 | +0.033 20 +0.000 | +0.021 23 | 20 | -0.020 -0.041 | 0.8 | 0.4 | △ | △ | △ | △ | |||||

| 22 | 25 | 25 | +0.075 +0.035 | 40.033 22 +0.000 | +0.021 25 | 22 | -0.020 -0.041 | 0.8 | 0.4 | △ | △ | △ | △ | |||||

| 24 | 27 | +0.075 27 0.035 | +0.033 24 +0.000 | +0.021 27 | 24 | -0.020 -0.041 | 1.0 | 0.5 | △ | △ | △ | △ | △ | |||||

| 25 | 28 | 28 | +0.075 +0.035 | +0.033 25 +0.000 | +0.021 28 | 25 | -0.020 -0.041 | 1.0 | 0.5 | △ | △ | △ | △ | |||||

| 26 | 30 | 2-0.035 | +0.075 30 +0.035 | +0.033 26 +0.000 | +0.021 30 | 26 | -0.020 -0.041 | 1.0 | 0.5 | △ | △ | △ | △ | |||||

| 28 | 32 | +0.085 32 +0.045 | +0.033 28 +0.000 | +0.025 32 | 28 | -0.020 -0.041 | 1.0 | 0.5 | △ | △ | △ | △ | △ | |||||

| 30 | 34 | 34 | +0.085 +0.045 | +0.039 30 +0.000 | +0.025 34 | 30 | -0.020 -0.041 | 1.2 | 0.6 | △ | △ | △ | △ | △ | ||||

| 32 | 36 | 36 | +0.085 +0.045 | +0.039 32 +0.000 | +0.025 36 | 32 | -0.025 -0.050 | 1.2 | 0.6 | △ | △ | △ | △ | △ | ||||

| 35 | 39 | 39 | +0.085 +0.045 | 40.039 35 +0.000 | +0.025 39 | 35 | -0.025 -0.050 | 1.2 | 0.6 | △ | △ | △ | △ | △ | ||||

| 38 | 42 | 42 | +0.085 +0.045 | +0.039 38 40.000 | +0.025 42 | 38 | -0.025 -0.050 | 1.2 | 0.6 | △ | △ | △ | △ | △ | ||||

| 40 | 44 | 44 | +0.085 +0.045 | +0.039 44 +0.000 | +0.025 44 | 40 | -0.025 -0.050 | 1.2 | 0.6 | △ | △ | △ | △ | △ | ||||

125x115x78mm

model: Isuzu

location: Balance shaft

134x30x50mm

model: Qingling Isuzu

location: Steering joint main

108/80x70x90mm

model: Xuanhua 140

location: Bulldozer support wheel

42x35x89mm

model: EQ153

location: Rear steel plate

110x100x91mm

model: Hino, Dongfeng

location: Balance Shaft

49*45*26/45mm

model: CUMMINS

location: Connecting rod

Why Choose Bimetal Bushings?

Key Benefits:

- High Load Capacity: The steel backing offers excellent strength, allowing the bimetal bushing to withstand heavy loads and high mechanical stresses without deformation.

- Superior Wear Resistance: The sintered bronze or copper alloy inner layer offers excellent anti-wear properties, reducing friction and extending the lifespan of the components.

- Efficient Heat Dissipation: The bimetal structure helps dissipate heat generated by friction, maintaining optimal performance even in high-temperature applications.

- Cost-Effective Solution: Bimetal bushings offer a balance between cost and performance, making them an economical choice for industrial equipment.

- Easy Installation and Maintenance: These bushings are designed for easy installation and can be used in applications that require minimal lubrication, reducing downtime and maintenance costs.

Technical Specifications

Bimetal bushings are designed to meet the toughest industrial demands. Below are the detailed technical specifications to ensure they fit your application needs:

- Material Composition: High-quality steel backing + sintered bronze/copper alloy inner layer

- Max Static Load: 150N/mm²

- Max Dynamic Load: 60N/mm²

- Coefficient of Friction: 0.04-0.12 (with lubrication)

- Operating Temperature Range: -40°C to +250°C

- Max Sliding Speed: 2.5 m/s (with lubrication)

- Tolerances: Precision-manufactured to industry standards (ISO/ANSI) for high performance in critical applications.

Case Studies — Proven Performance in Demanding Environments

Bushing Applications

Versatile Applications for Various Equipment

- 1. Construction Machinery

- 2. Automotive Industry

- 3. Agricultural Machinery

- 4. Industrial and Hydraulic Systems

Combine Harvester

Crane

Bulldozer

Loader

Graders

Automobile

Truck

Tractor

Dump Truck

Excavator

Custom Services and Solutions

We understand that every customer’s needs may vary based on specific applications and equipment requirements. That’s why we offer fully customized solutions for bimetal bushings, including:

Free consultation

Communicate with us to clarify the requirements

Free design

Customize your product according to your needs

Sample making

Confirm the drawings and arrange for sampling

Sample confirmation

Customer confirms sample and arranges production

Finished inspection

Inspect the finished product and arrange for shipment

FaQ

Are you a factory?

Of course, we are a manufacturer that can complete the entire production line from raw materials to finished bushing products.

What bushings do you production?

We mainly produce various self-lubricating bushings. Please refer to our product solutions or contact us for details

What is a bushing?

What is the general process for manufacturing bushings?

Bushing manufacturing involves several key steps:

Material Selection: Choosing the appropriate material such as bronze, rubber, or plastic, depending on the application.

Forming: Techniques like casting, pressing, or extrusion are used to shape the raw material into a bushing.

Heat Treatment: For metal bushings, heat treatment is applied to increase strength and wear resistance.

Finishing: This step involves precision machining to achieve the required dimensional tolerances and surface finish.

Surface Treatment: A coating may be applied for corrosion resistance or lubrication purposes, such as zinc plating or Teflon coating.

What materials are commonly used in bushing production?

Common materials used in bushings include:

Bronze: Known for its durability and low friction, often used in heavy-duty applications.

Rubber: Used for vibration dampening in automotive and machinery applications.

Nylon/Polymer (like PTFE): Provides self-lubrication and is ideal for low-load, low-friction environments.

Steel: Used for high-load applications, often combined with a softer material like bronze or plastic as the lining.

How are bushing dimensions and tolerances maintained during production?

What surface treatments are used for bushings?

Bushings often undergo surface treatments to enhance their properties:

Zinc or nickel plating: Protects the metal surface from corrosion.

Teflon (PTFE) coatings: Provide low friction and self-lubricating properties.

Phosphating or black oxide coating: Improve wear resistance and reduce the potential for galling (severe adhesion between surfaces in motion).

What are the challenges in bushing production?

Key challenges include:

Maintaining precision: Ensuring dimensional accuracy across large production runs can be difficult, especially for complex shapes.

Material selection: Using the wrong material could result in failure under stress or environmental conditions.

Surface finish quality: Achieving smooth surface finishes is crucial to reducing friction and wear.

Can bushings be custom-made?

What environmental factors are considered in bushing production?

Manufacturers consider several environmental aspects:

Material sustainability: Using eco-friendly or recyclable materials.

Waste management: Minimizing production waste and properly handling hazardous materials.

Energy consumption: Optimizing energy use in production processes to reduce carbon footprint.

What is the purpose of a bushing?

How can I tell when a bushing needs to be replaced?

Signs that a bushing may need replacement include:

Cracks, splits, or visible damage.

Increased noise, such as squeaking or grinding.

Excessive play or movement in the component where the bushing is installed.

Vibration or instability in the machinery or equipment.

How do I maintain bushings?

What is the difference between a bushing and a bearing?

How long do bushings last?

More Related Bushing products

Contact Us for More Information

We not only provide high-quality self-lubricating bushings but also offer comprehensive technical support and after-sales service to ensure your equipment always operates at peak performance. If you have any questions or need a quote, please feel free to contact us at any time.

Tel/Whatsapp: +86 136 4583 4002

Email:ivan@mybushing.com