Product Overview

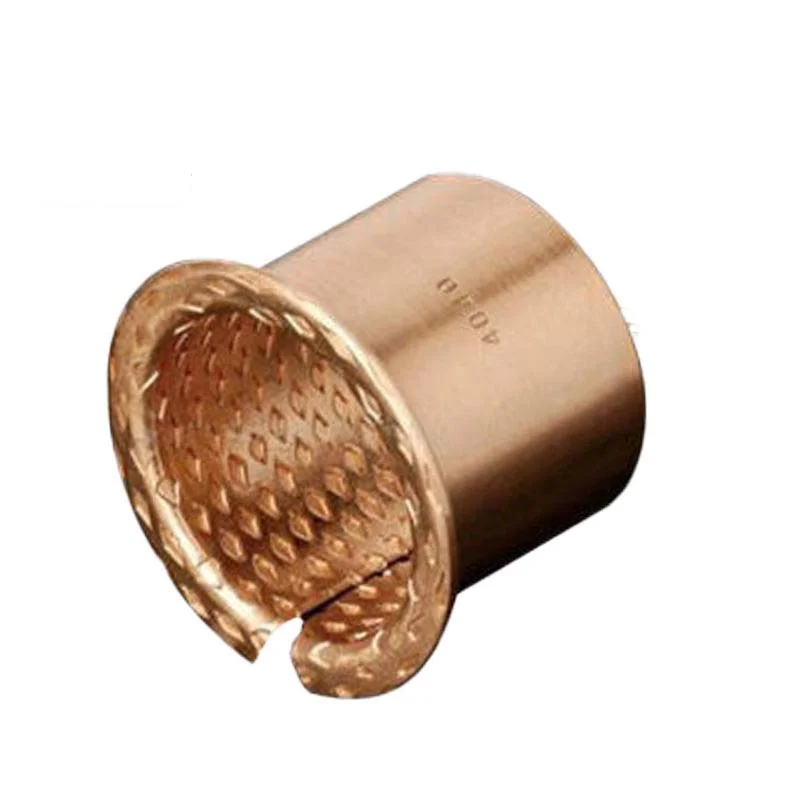

Our Wrapped Bronze Bushing is made from high-quality, high-strength bronze alloy and is designed for long-lasting, high-load applications. Its self-lubricating feature significantly reduces the need for maintenance, extending the service life of your equipment. This makes it an ideal choice for industries such as construction machinery, agricultural equipment, and automation systems.

Table Of Contents For This Page

To make sure you can find the information you want quickly,

we have prepared this content directory that will jump to the corresponding location when you click on it.

Bushing Material

They are ideal for a variety of heavy-duty applications, ensuring consistent performance even under harsh conditions.

Materials and Structure

Our bushings are made from top-grade bronze alloys that meet international standards, offering excellent corrosion resistance and high load-bearing capacity

- Outer Layer (Bronze Layer):

- The outermost layer is usually made of bronze, a copper-based alloy primarily consisting of copper and tin, with possible additions of other elements like zinc, lead, or phosphorus to enhance specific properties.

- The bronze layer provides mechanical strength and corrosion resistance, allowing the bearing to operate under minimal or no lubrication conditions.

- Middle Layer:

- Some high-performance wrapped bronze bushings incorporate an intermediate layer of special materials such as polytetrafluoroethylene (PTFE) or other plastics between the bronze and the shaft.

- This layer primarily serves to reduce friction and provide additional lubrication.

- Inner Surface:

- The inner layer may include lubrication grooves or oil holes designed to store lubricant, ensuring continuous lubrication.

- Such designs extend the bearing’s lifespan and reduce maintenance needs.

Comparative Table of Bronze Grades for Bushings

| Bronze Grade | Composition | Wear Resistance | Operating Environment | Lifespan | Analysis |

| C93200 | 83% Copper, 7% Tin, 7% Lead, 3% Zinc | High | Moderate loads, occasional dry running | High | Popular for general machinery due to good machinability and durability. |

| C95400 | 85% Copper, 11% Aluminum, 3% Iron, 1% Other | Very High | High loads, high impact, marine environments | Very High | Best for extreme conditions, offers highest wear resistance and longest lifespan. |

| C86300 | 63% Copper, 25% Zinc, 3% Manganese, 9% Aluminum | High | High loads, rough environments | High | Suitable for heavy-duty applications with high strength and toughness. |

| C90500 | Mostly Copper and Tin | Medium | Moderate loads, requires lubrication | Medium | Ideal for applications where some lubrication is provided and moderate wear resistance is needed. |

| C90700 | High Tin content | Medium to High | High loads, requires good lubrication | Medium to High | Provides enhanced wear resistance under lubricated high-load conditions. |

Bushing Size

| ID(mm) | OD(mm) | L(mm) | ID(mm) | OD(mm) | L(mm) |

| 8 | 10 | 10 | 50 | 55 | 65 |

| 10 | 12 | 15 | 55 | 60 | 70 |

| 12 | 14 | 20 | 60 | 65 | 75 |

| 15 | 17 | 25 | 65 | 70 | 80 |

| 18 | 20 | 30 | 70 | 75 | 85 |

| 20 | 23 | 35 | 75 | 80 | 90 |

| 25 | 28 | 40 | 80 | 85 | 95 |

| 30 | 34 | 45 | 85 | 90 | 100 |

| 35 | 39 | 50 | 90 | 95 | 105 |

| 40 | 44 | 55 | 95 | 100 | 110 |

| 45 | 49 | 60 | 100 | 105 | 115 |

Key Considerations:

- Size Suitability: When selecting sizes, ensure that the chosen dimensions are appropriate for your specific applications and assembly space. Different machinery might require specific inner diameters, outer diameters, and lengths.

- Customization Services: We offer customization services, allowing the production of bushings with special dimensions tailored to your specific requirements.

- Inquiry and Procurement: Before making a purchase, it is advisable to contact multiple suppliers to compare prices and delivery times, selecting the optimal supply solution.

I hope this expanded size list helps you find the suitable bushing dimensions for your needs. If you have more specific requirements or further questions, feel free to ask.

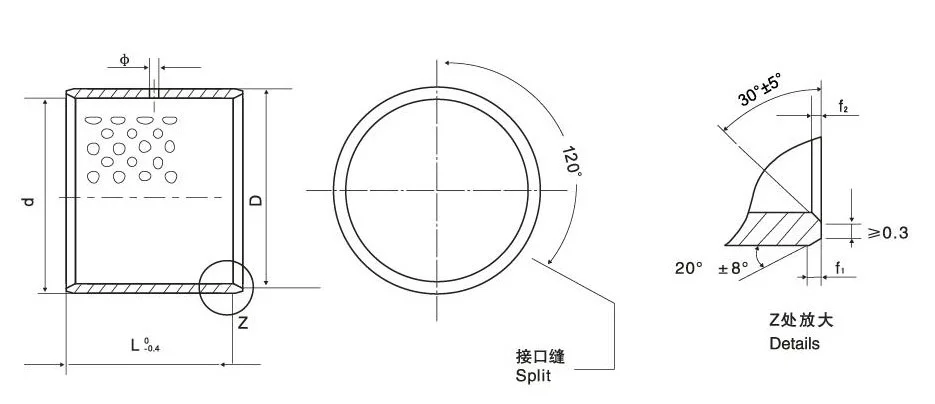

Bushing Shape

The different bushing shapes allow bushings to be widely used in various mechanical structure parts, such as the moving parts inside cars or the connecting parts on industrial machinery or other situations where there’s friction and wear that needs to be beaten down.

Cylindrical

Flanged

Advantages of wrapped bronze bushings

1. High-Quality Materials & Manufacturing Excellence

- Material: We use CuSn8 or CuSn6 high-strength bronze alloy, which is known for its excellent wear resistance and anti-corrosion properties. This ensures that the bushing performs well in both dry and lubricated environments, even in extreme conditions.

- Self-Lubricating Feature: The bushings are equipped with lubrication grooves or holes on the inner surface, allowing for automatic lubrication during operation, reducing the need for frequent maintenance and extending the product’s lifespan.

2. Precision Engineering & Tolerance Control

- Exacting Tolerance: Our Wrapped Bronze Bushings are manufactured with precision to meet international tolerance standards. The typical tolerance for most applications is H7/h8, but we also offer customized dimensions to fit specific client needs.

- Why This Matters: Tighter tolerances help reduce play and movement within the machinery, improving performance and reducing wear and tear, which ultimately lowers your operational costs.

- Customized Solutions: If your machinery requires bushings with special dimensions or specifications, we can provide tailor-made products to ensure a perfect fit for your application.

3. Outstanding Durability and Performance in Harsh Environments

- Wear and Corrosion Resistance: Designed to handle high loads and extreme environments (e.g., dust, mud, chemicals, or moisture), our bronze bushings significantly extend the service life of machinery, even in outdoor or abrasive working conditions

Mechanical and Physical Properties

- Max Static Load: 140 N/mm² – Indicates the maximum static load the bushing can withstand without deformation.

- Coefficient of Friction: Ranges from 0.05 to 0.20, varying with working conditions – Reflects the efficiency of movement and energy loss due to friction.

- Operating Temperature Range: -40°C to +130°C – Specifies the temperature range within which the bushing operates effectively.

- Max Sliding Speed: 2.5 m/s – The highest speed at which the bushing can operate without significant wear.

- Wear Rate: High wear resistance under normal operating conditions, suitable for medium load and low-speed applications – Highlights the durability of the bushing in typical usage scenarios.

Applications and Usage

- Suitable for Medium Load Applications: Ideal for applications where moderate loads are applied.

- Low-Speed Environments: Best used where operational speeds are relatively low to maximize lifespan and performance.

- Varied Temperature Environments: Capable of performing in a wide range of temperatures, from very cold to moderately hot.

Bushing Applications

Versatile Applications for Various Equipment

Construction Machinery: Excavators, bulldozers, loaders, and other equipment that require high-load and self-lubricating parts.

Agricultural Machinery: Harvesters, tractors, and other equipment in need of wear-resistant bearing solutions.

Automotive Industry: Suspension systems, steering components, and other parts that require self-lubrication and wear resistance.

Hydraulic Systems: Guiding and sealing applications in hydraulic cylinders and piston rods that require lubrication and wear protection.

Combine Harvester

Crane

Bulldozer

Loader

Graders

Automobile

Truck

Tractor

Dump Truck

Excavator

Custom Services and Solutions

Personalized Design Support

We understand that each customer’s needs may vary, which is why we offer customized solutions tailored to different equipment applications. We provideself-lubricating bushings in specific sizes, materials, and thicknesses to match your unique requirements. No matter what industry or application your equipment is used in, we can offer the optimal product selection to meet your needs.

Free consultation

Communicate with us to clarify the requirements

Free design

Customize your product according to your needs

Sample making

Confirm the drawings and arrange for sampling

Sample confirmation

Customer confirms sample and arranges production

Finished inspection

Inspect the finished product and arrange for shipment

Why Choose Us?

Personalized Design Support

- Proven Material Quality: We use only top-quality bronze alloy (CuSn8/CuSn6), ensuring long-lasting, reliable performance.

- Precision Manufacturing: Strict tolerance control guarantees high compatibility with your equipment, minimizing friction and wear.

- Tailored Solutions: Custom bushing sizes and specifications are available to meet the exact needs of your machinery.

- Comprehensive Support: Our after-sales service ensures that you’re never left without help, from product delivery to installation and ongoing use.

If you’re interested in learning more about our Wrapped Bronze Bushings or if you have specific requirements, please don’t hesitate to reach out. We are ready to provide you with customized quotes and answer any technical questions you may have to ensure that our bushings perfectly meet your business needs.

Stringent Quality Control & Certifications

- Material Certification: Every batch of our bushings undergoes rigorous testing to ensure it meets international ISO standards. We also provide material composition reports to ensure that buyers receive exactly what they ordered.

- Dimensional Accuracy: Our bushings are subject to strict quality checks, ensuring that every product meets its precise dimensional specifications. This guarantees a perfect fit for your machinery, reducing any risks of premature failure or wear.

Comprehensive After-Sales Service & Fast Delivery

- Technical Support: Whether you need help with installation, troubleshooting, or specific technical guidance, our dedicated support team is available to assist you. We are committed to ensuring your complete satisfaction from product inquiry to installation and beyond.

- Quick Delivery & Supply Chain Reliability: With stable production lines and adequate stock, we offer fast delivery times to ensure you get the parts you need when you need them. Bulk orders are accommodated with flexible shipping options and competitive pricing.

FaQ

Are you a factory?

Of course, we are a manufacturer that can complete the entire production line from raw materials to finished bushing products.

What bushings do you production?

We mainly produce various self-lubricating bushings. Please refer to our product solutions or contact us for details

What is a bushing?

What is the general process for manufacturing bushings?

Bushing manufacturing involves several key steps:

Material Selection: Choosing the appropriate material such as bronze, rubber, or plastic, depending on the application.

Forming: Techniques like casting, pressing, or extrusion are used to shape the raw material into a bushing.

Heat Treatment: For metal bushings, heat treatment is applied to increase strength and wear resistance.

Finishing: This step involves precision machining to achieve the required dimensional tolerances and surface finish.

Surface Treatment: A coating may be applied for corrosion resistance or lubrication purposes, such as zinc plating or Teflon coating.

What materials are commonly used in bushing production?

Common materials used in bushings include:

Bronze: Known for its durability and low friction, often used in heavy-duty applications.

Rubber: Used for vibration dampening in automotive and machinery applications.

Nylon/Polymer (like PTFE): Provides self-lubrication and is ideal for low-load, low-friction environments.

Steel: Used for high-load applications, often combined with a softer material like bronze or plastic as the lining.

How are bushing dimensions and tolerances maintained during production?

What surface treatments are used for bushings?

Bushings often undergo surface treatments to enhance their properties:

Zinc or nickel plating: Protects the metal surface from corrosion.

Teflon (PTFE) coatings: Provide low friction and self-lubricating properties.

Phosphating or black oxide coating: Improve wear resistance and reduce the potential for galling (severe adhesion between surfaces in motion).

What are the challenges in bushing production?

Key challenges include:

Maintaining precision: Ensuring dimensional accuracy across large production runs can be difficult, especially for complex shapes.

Material selection: Using the wrong material could result in failure under stress or environmental conditions.

Surface finish quality: Achieving smooth surface finishes is crucial to reducing friction and wear.

Can bushings be custom-made?

What environmental factors are considered in bushing production?

Manufacturers consider several environmental aspects:

Material sustainability: Using eco-friendly or recyclable materials.

Waste management: Minimizing production waste and properly handling hazardous materials.

Energy consumption: Optimizing energy use in production processes to reduce carbon footprint.

What is the purpose of a bushing?

How can I tell when a bushing needs to be replaced?

Signs that a bushing may need replacement include:

Cracks, splits, or visible damage.

Increased noise, such as squeaking or grinding.

Excessive play or movement in the component where the bushing is installed.

Vibration or instability in the machinery or equipment.

How do I maintain bushings?

What is the difference between a bushing and a bearing?

How long do bushings last?

More Related Bushing products

Contact Us for More Information

We not only provide high-quality self-lubricating bushings but also offer comprehensive technical support and after-sales service to ensure your equipment always operates at peak performance. If you have any questions or need a quote, please feel free to contact us at any time.

Tel/Whatsapp: +86 136 4583 4002

Email:ivan@mybushing.com