Home » Self lubricating bushings » Why Is It Called a Bushing?

Why is it called a bushing?

Do you know what a bushing is? Sometimes called a bush bearing, bushings are critical and widely-used parts in an untold number of industrial and mechanical applications. But have you ever wondered why they are called “bushings?” We’re going to explore the answers to this question, what a bushing is, what you need to know about bushings, and what people who buy them for a living, stock them for sale or design them for various equipment want to know everything about bushings.

Table of Contents

1. What is a Bushing?

A bushing is a cylindrical shaped mechanical device that you put into two things that are moving against each other to reduce friction. It creates a surface for things to move on that isn’t the things that are moving, and you reduce wear. The name probably comes from the old word “bush,” which is the British word for a sleeve or lining. Bushings are everywhere and used in industries like automotive, lawn and garden, agriculture, construction, and general engineering machinery.

2. Why are Bushings Essential in Modern Machinery?

3. What is the Self-lubricating Called?

A bearing like this is sometimes referred to as a maintenance-free bearing. It doesn’t require you to periodically add lubricant to it to keep it running. Self-lubricating bearings come pre- oiled or with material that is designed to run without oil.

For example, you might have heard of DU/SF-1 or DX/SF-2. These are self-lubricating bushings that have a composite structure with a PTFE /Teflon or other type of layer in them to keep them running basically without friction for a long time. We see these frequently used in applications where it’s difficult to maintain oil in a bearing, such as in agricultural machinery, construction equipment, and various automotive parts.

4. What Materials Are Bushings Made From?

You can make bushings from different materials depending on the application and what you are working with.

Bronze is good for heavy loads and wear.

We have made bimetal bushings (steel backed with a bronze or alloy).

We make them out of PTFE, or Teflon, for self-lubricating bushings which have low friction and need no lubrication.

We make it out of a powder for precision fit bushings. We also use specific copper alloys for high temperature or corrosion wars.

It all depends on the load, speed, temperature and other things related to your application.

If you would like to learn more about other lining products, or if you have any questions about lining, please feel free to contact us.

5. What Is Another Name for a Bush Bearing?

People also call bushings different things as well. People might refer to a bush bearing as a plain bearing、sleeve bearing、journal bearing、bushings、slide bearings and self Lubricating Bushing etc. All of this stuff is synonyms about what people call bushings.

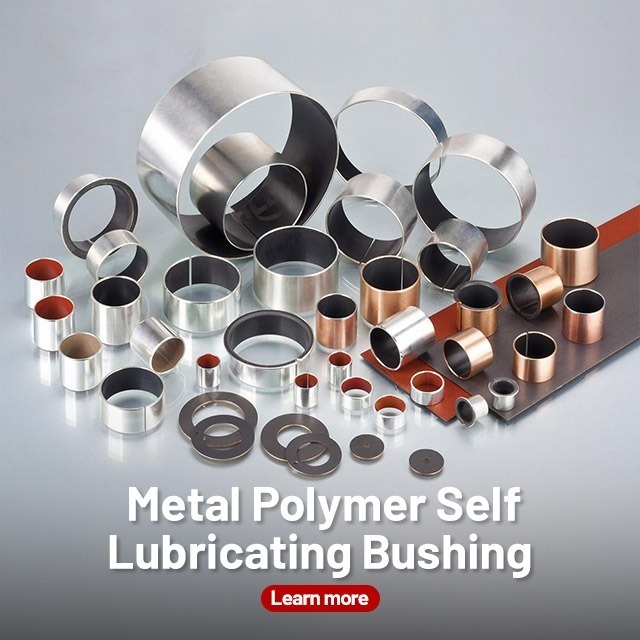

6. What Does a Bushing Look Like?

They are cylindrical like a little sleeve or ring thing. Bushings come in all different sizes and shapes to do all sorts of stuff. Bushings can also have various different surfaces such as grooves or pockets for holding a lubricant. Some bushings have graphite plugs embedded in them because graphite has some self-lubricating properties. Bushings can have different coated or lined surfaces to reduce friction. Bushings are compact and versatile little things great for all kinds of machinery and mechanical stuff out there.

7. The Advantages of Self-Lubricating Bearings

8. How to Choose the Right Bushing for Your Application

9. Conclusion

100000+ Types of Bushings – Contact Us for Details