Home » Self lubricating bushings » What is the difference between a bushing and a sleeve?

What is the Difference Between a Bushing and a Sleeve?

“A bushing is a bearing to reduce friction and wear between moving parts. A sleeve is a cylindrical shape used as a shield. While a sleeve can serve as a bearing, because of the material and shape, it’s not designed to support a significant amount of load.”

So in today’s article, I want to talk to you about bushings versus sleeves. What’s the big difference? What is a sleeve bushing? What are they used for? Do sleeve bearings need lubrication?

Table of Contents

What is a Sleeve Bushing?

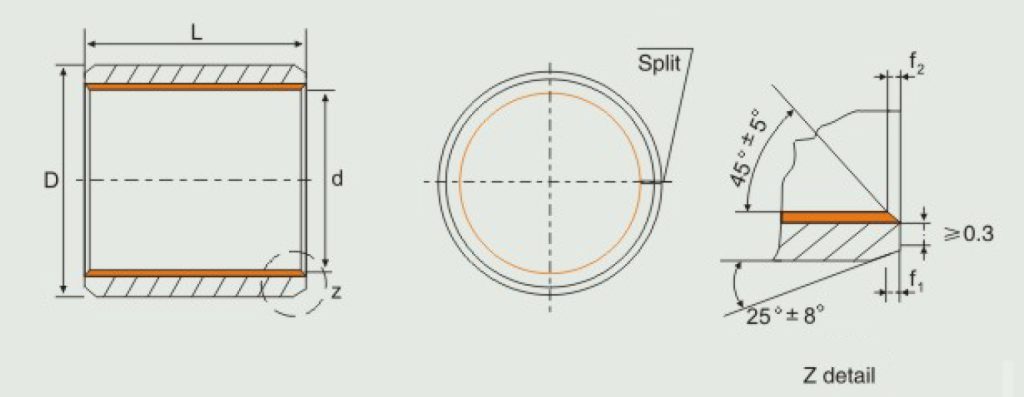

A sleeve bushing is a type of bushing with a cylindrical tubular design that fits nice and snug over a shaft to prevent the shaft from touching the housing, reduces friction and wear, and ensures longer bearing life.

Key Features of Sleeve Bushings:

Shape: Cylindrical and tubular, designed to fit around a shaft.

What it does: It reduces friction between a shaft and a housing.

What it’s made of: Metal (bronze, steel), composites (layer steel, composite materials) or plastic (PTFE, nylon).

What you do with sleeve bushings? Apply them in automotive systems such as suspension and steering components. Use them in all kinds of commercial and industrial wiring such as conveyors, pumps, and compressors. Use them in any small motor or fan to cut down on the noise and the friction in the mechanism.

What is a Sleeve Bearing Used for?

The sleeve bearing is a specific type of plain bearing that utilizes a sleeve-shaped design to support a rotating shaft. The entire idea of the sleeve bearing is to reduce friction and stabilize the shaft as it’s turning or sliding inside that bearing.

Key Features of Sleeve Bearings:

Do Sleeve Bearings Need Lubrication?

Some sleeve bearings need to be lubricated, and others don’t. It all depends on the type of bearings being used. Some bearings need oil or grease because they aren’t designed to be self-lubricating. On the other hand, some sleeve bearings are specifically designed to be self-lubricated, which means you don’t have to do anything with them.

Different Sleeve Bearings and How They Get Lubrication:

Oil-Lubricated Sleeve Bearings:

Need the oil or grease to be put into them periodically to keep them from wearing out and generating heat.

Ideal in high-speed or high-wear applications.

Self-Lubricating Sleeve Bearings:

The bearings are made from materials like oil-impregnated bronze or PTFE that, as they wear, release lubrication into the area between the two surfaces.

This type is often used in tough applications where maintenance is not readily accessible or is cost-prohibitive.

Dry-Running Sleeve Bearings:

Low coefficient of friction and can run without being lubricated.

The materials include high-tech plastics or high-tech composites that generally need no lubrication. Is it good that they lubed them?

Whether you put oil directly into a sleeve, have it squeezed between a spring, or is built into the material, in general, that’s going to make those bearings last longer. It’s a more efficient way to go about running a piece of moving equipment

What are the Differences between Bushing and Sleeve?

While bushings and sleeves are very similar in functionality, they do very different things and have very different design elements. Let me show you a quick comparison.

Key Differences:

Feature | Bushing | Sleeve |

Shape | Shorter and smaller, often cylindrical or ring-like. | Longer, tubular, and covers a larger surface area. |

Primary Function | Reduces friction and serves as a spacer or liner. | Specifically supports shafts in rotational or sliding motion. |

Material | Metal (bronze, steel), plastic, or composite. | Similar materials, but often focuses on self-lubrication. |

Applications | Used to line holes or support pins and rods. | Used to encase rotating shafts for stability. |

Quick Summary:

Bushings are usually smaller and used to line holes or reduce the amount of friction in a hole or pin.

Sleeves, on-the-other-hand, are usually longer and designed to completely surround and support the shaft over a longer area.

When to Use a Bushing vs. a Sleeve

If you want to reduce the friction and wear or need a spacer in a joint or to reduce movement between parts, choose a bushing.

If you need something to go around and support a shaft that is going to rotate or slide where you want as much support as possible with the least amount of friction over the largest area, pick a sleeve.

Key Takeaways

Sleeve bushings and sleeve bearings are about shaft support. Understanding the difference is important for knowing when a bushing will work over a sleeve bearing and when you need a functional bearing to keep the shaft spinning.

When you understand the differences, you put yourself on the right path. Or if you need a little bushing to help out a little joint, you are already a winner, or if you need a sleeve bearing to make something go, now you know what to get.

100000+ Types of Bushings – Contact Us for Details