Home » Self lubricating bushings » Are sleeve bearings good?

Are Sleeve Bearings Good?

Table of Contents

What are Sleeve Bearings and How do They Work?

Understanding what sleeve bearings (also known as bushings or plain bearings) are and see how they work is the first step to determining whether they’re a good fit for the equipment you work on. Sleeve bearings are cylindrical components that support a rotating shaft and reduce friction by providing a smooth surface for the shaft to rotate within. Sleeve bearings are usually made of metals, bronze, or composite materials that work well for a lot of different mechanical systems.

What Are the Benefits of Sleeve Bearings?

What Are the Disadvantages of Sleeve Bearings?

How to Lubricate a Sleeve Bearing?

Proper lubrication is crucial for the smooth operation of sleeve bearings. Here are several lubrication methods to consider:

Are Sleeve Bearings Suitable for High-speed or High-load Applications?

The answer depends on several factors:

How to Choose the Right Sleeve Bearing for My Application?

Choosing the right sleeve bearing for your application requires careful consideration of several factors, including:

“If you’re working with someone you trust and somebody who knows your application, that’s been really successful for me over many years in evaluating bearings to make the best choice as to what one to use.”

Conclusion: Are Sleeve Bearings Good for Your Machinery

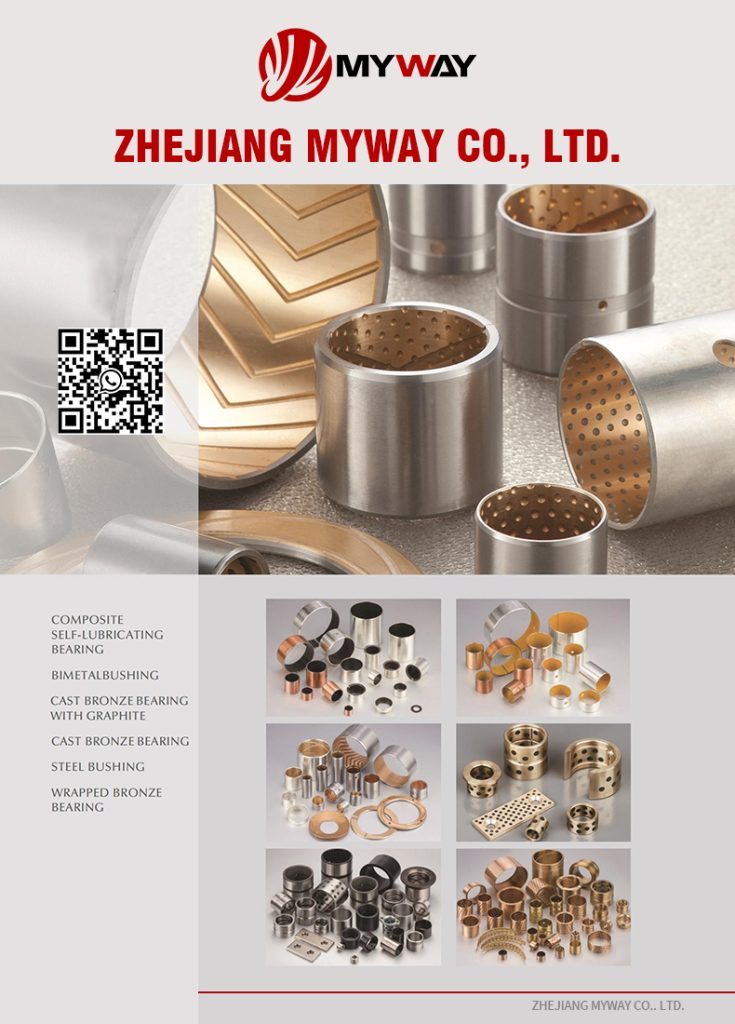

100000+ Types of Bushings – Contact Us for Details