Home » Self lubricating bushings » What is the Best Bronze for Bushings? A Complete Guide for B2B Buyers

What is the Best Bronze for Bushings?

The best bronze to use for bushings is often Phosphor Bronze (CuSnPb) because it has excellent wear resistance, a low coefficient of friction, and is very durable. And while not quite as popular as Phosphor Bronze, Aluminum Bronze (CuAl), Beryllium Bronze (CuBe), and Tin Bronze (CuSn10) are also ideal material choices for making bushings.

To choose the right bronze for your bushings, you need to know about the different kinds and understand the strengths and weaknesses of the bronze. Bronze is a common material for bushing because of its great strength, corrosion resistance, and wear properties.

When we deal with B2B or when we have to buy things for our businesses, especially in industries like engineering, automotive, and construction, and you want to take advantage of this knowledge. Now you have a leg up on everyone else because you know the best bronze to use for special bushings for heavy duty.

Table of Contents

1. Types of Bronze Used for Bushings

1.1 Phosphor Bronze (CuSn)

Phosphor bronze is a bushing material that people often prefer due to its excellent wear characteristics and fatigue properties. It is a copper-tin alloy that has a small percentage of phosphorus added to the mix, making it very hard and resistant to abrasion and corrosion, and corrosion while maintaining good strength under high loads and stress.. It is a firm, strong material with good elasticity, so it’s a good choice for automotive, marine, and heavy machinery applications.

1.2 Aluminum Bronze (CuAl)

1.3 Tin Bronze (CuSn10)

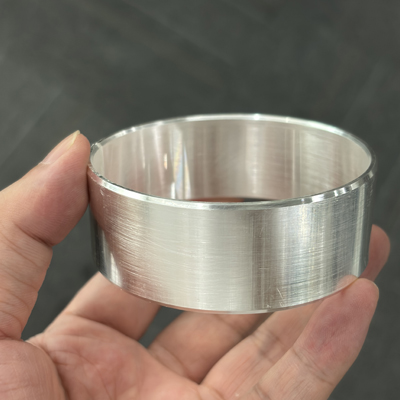

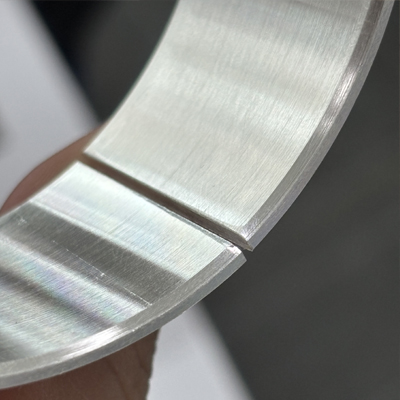

1.4 Beryllium Bronze (CuBe)

A recent client of ours used the beryllium bronze bushing in mining machinery. It is a relatively special bronze bushing made of BeCu material that has a silver plating on the surface. There are not many companies in China that produce this special material. If you need this part, feel free to consult at any time.

2. What Makes the Best Bronze for Bushings?

3. Conclusion: Which Bronze is Best for Your Bushing Application?

100000+ Types of Bushings – Contact Us for Details