Home » Self lubricating bushings » What is the Most Durable Bushing?

Why is it called a bushing?

What is the Most Durable Bushing?

When it comes to having bushings that are going to last, making the right choice on the bushing material is critical. In this guide, I’ll show you some of the most durable bushings you can get.

Contents

It is recognized in circles of experts that bronze bushings are incredibly durable, resist wear and last a long time. Manufacturing, automotive, and heavy equipment people know bronze bushings are capable of high temperatures, harsh conditions, and heavy pressure.

Steel bushings, especially stainless steel and high-carbon steel, are designed to take huge pressure and are intended for heavy-duty applications. These are typically installed in various machinery, industrial equipment, construction equipment and even in bushings for mining equipment.

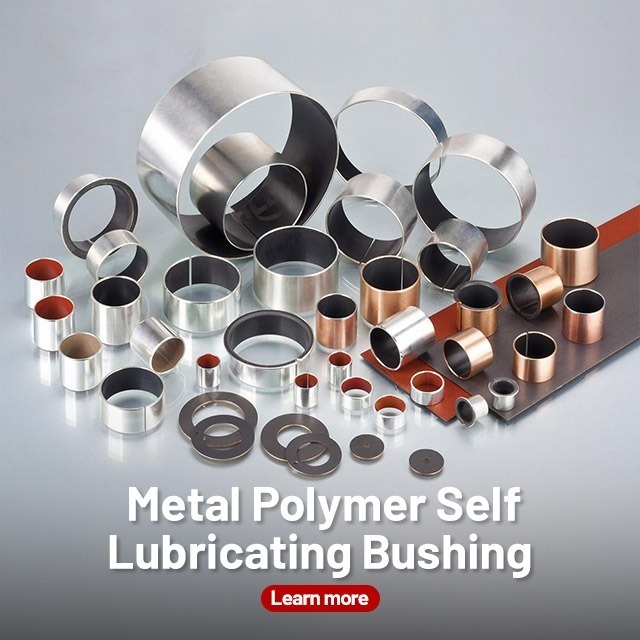

When we talk about self-lubricating bushings, they last a long time, and you don’t typically have to do anything to them. These bushings use graphite, PTFE, or oil-impregnated materials, so you don’t have to lubricate them; great for applications in harsh environments.

4. What is the Advantage of Bushing?

Why do people use bushings in the first place? Well, bushings obviously have advantages; otherwise people wouldn’t use them. Let’s take a look at a few of the advantages.

4.1 Cost-Effective and Economical Solution

Bushings are cheaper than standard ball or roller bearings. In other words, if you need to save some serious money on the equipment you’re building, use a bushing. They’re a cheaper solution any company can find. You can see why a bearing company loves to sell bushings because they do high volume business selling this product to buyers.

4.2 Compact and Space-Saving Design

Bushings are compact which is great for situations with tight space. (For example: automotive parts, ag machinery parts, little small machine parts, etc.)

4.3 Low Maintenance Requirements

Bushings, especially ones that are self-lubricating, require virtually no maintenance. This means less downtime, which saves you money and labor. This is important whenever your equipment is in a remote location or hard-to-reach spot so you don’t have to maintain it all the time.

4.4 Improved Shock Absorption and Vibration Control

Bushings like Polyurethane Bushings and rubber bushings do a great job absorbing shock and cutting down on vibration. This is critical in areas like the automobile and machinery businesses where having the ability to reduce vibration can make things work better and last longer.

4.5 Versatility Across Different Industries

Construction machinery – required. Automotive – they use bushings. There’s a lot of different types of bushings around and of course there is a variety of materials that you can make bushings out of metal, plastic, composites, etc.

5. When Should You Use a Bushing?

When to use a bushing? Bushings are a perfect solution in many cases. Here’s when you need to use a bushing

5.1 Low-Speed, Low-Load Applications

For slow-speed, low-load applications, they are great at what they do. It’s an easy way to reduce friction and wear in something that probably doesn’t need the sophistication of a bearing. A perfect application example is a small motor, fan, or on a shaft in a household appliance

5.2 Compact Equipment or Limited Space

Bushings make sense when you have limited space like you do in any automotive component or small piece of machinery. Bushings also let you shrink the size of your mechanical assemblies without giving up performance.

5.3 Harsh or Remote Environments

Now if you’re in a harsh environment where you can’t use, or don’t want to use, lubrication to maintain a bushing (e.g. mining, construction, agricultural) then a self-lubricating bushing will do everything you want it to do without having to lift a finger (or do any maintenance).

5.4 Vibration and Noise Reduction

On equipment that has a lot of vibration or is subjected to impact, you use bushings like urethane bushings and rubber bushings to absorb the shock and quiet the vibration of the equipment so it works better.

6. How Do Self-Lubricating Bushings Work?

7. Conclusion

100000+ Types of Bushings – Contact Us for Details