Home » Steel Bushings

Myway: Trusted Steel Bushing Manufacturer with Short Lead Time

High-Quality Sleeves, Flanged & Threaded Bushings for Industrial Applications

- ISO9001 certified & food-grade compliant

- Premium metal alloys with corrosion resistance

- Quick delivery: 7 days or less for standard orders

- 100% inspection ensures tighttolerances (±0.01″)

- Good resistance to fatigue under high temperature

What is Steel Bushing?

Steel bushings are mechanical parts made by powder metallurgy, casting and other processes. They are mainly made of carbon steel, stainless steel, alloy steel, etc., and can maintain high load capacity and excellent corrosion resistance even under harsh operating conditions.

The steel bushings have the functions of reducing friction, dispersing loads, and supporting rotating or sliding shafts inside the machinery, so they are widely used in automotive control arms, industrial machinery conveying systems, mining equipment and other fields.

Myway will perform a series of precision treatments on steel bushings to improve performance: through heat treatment, their hardness and durability are significantly improved; surface treatment processes such as phosphating, galvanizing or PTFE coating further improve corrosion resistance and reduce friction coefficient.

Steel Bushing Materials

Stainless Steel Bushing

Stainless steel bush made of SS304/316 offers high durability and corrosion resistance, making it suitable for environments with chemicals or seawater.

Carbon Steel Bushing

Due to its high strength, excellent machinability, and cost-effectiveness, carbon steel is one of the mainstream materials for threaded bushings.

Hardened Steel Bushings

The tensile strength of hardened steel bushings can reach 550N/mm². They are usually cylindrical, with flat or grooved sliding layer and can be greased.

Oil Impregnated Steel Bushing

Oil impregnated steel bushing is a kind of self-lubricating sliding bushing produced by powder metallurgy process, and the friction coefficient is usually between 0.08 and 0.15.

Graphite Impregnated Steel Bushings

Graphite impregnated steel bushing, also called iron bushing with graphite, is evenly embedded with graphite inside, it has the characteristics of self-lubrication and maintenance free.

Steel Bushing Materials

Steel Bushing Sleeve

The steel bushing sleeve is a standard cylindrical construction with no additional flanges or grooves, it is typically used for friction mitigation and load support in linear or rotary motion.

Flanged Bushing Steel

One end of the flange steel sleeve has a flange, which can minimize the friction between the shaft and the bushing. It is often used for axial positioning or bearing axial loads.

Small Steel Bushings

The inner diameter of small steel bushings ranges from 1/2 inch to 4-5/8 inch. It is precision machined by CNC or cold formed, and the diameter tolerance is within ±0.01mm.

Thin Wall Steel Bushings

The wall thickness of thin wall steel bushings does not exceed 5 mm at most. This design reduces the overall weight while improving the heat conduction efficiency.

Spring Steel Bushings

Made of highly elastic alloys like 65Mn, 50CrV4, etc., spring steel bushing has tensile strength of 1250-2200 N/mm², it can withstand repeated loads without permanent deformation.

Steel Shoulder Bushings

The shoulder steel bushing is integrated with a shoulder or flange at one end or both ends. The outer diameter of the flange is 20-30% larger than that of the bushing.

Custom Steel Bushings

Myway can carry out all-round customization according to your needs, such as size, manufacturing process, surface treatment, etc., or make solutions according to your application.

Benefits of Steel Bushings

Stable Structure

Usually made of high-quality carbon steel, alloy steel or stainless steel304/316, steel bushings have high strength and hardness and can withstand heavier loads.

Multiple Sizes

The diameter of steel bushings ranges from a few to hundreds of millimeters, which can meet the installation and lubrication requirements of various mechanical equipment.

Simple Operation

Steel bushings are usually compact and easy to install. In addition, they are self-lubricating, ensuring support stability while reducing downtime due to maintenance or wear.

Wear Resistance

Machining, heat treatment and other processes have greatly enhanced the surface hardness of the steel bushing, and its forming performance has also been further improved.

Corrosion Tolerance

Stainless steel bushings exhibit exceptional corrosion resistance against chemical erosion, ensuring long service life in marine, chemical or other corrosive environments.

Reducing Noise

The friction coefficient of steel bushings ranges from 0.15 to 0.20, and can absorb vibration and reduce noise, which helps to improve the smooth operation of the system.

Bronze Bushings vs. Steel Bushings

- Hardness:Steel bushings are harder than bronze bushings, especially the hardened steel, which can reach up to HRC 55. They are suitable for high-load applications with pressure ≥30MPa, and can also resist high-frequency impacts of mining crushers. Bronze bushings are more suitable for medium-load scenarios.

- Self-lubricating:The self-lubricating property of bronze bushings is superior to that of steel bushings. In addition to natural friction reduction, oil impregnated and graphite embedded bronze bushings are completely maintenance-free. Steel bushings are dependent on external lubrication and either have a self-lubricating coating or need to be lubricated periodically.

When you have a limited budget, need high-hardness and high-precision parts for a short period of time, steel bushings are your wise choice! If you are looking for self-lubricating, corrosion-resistant and long-term maintenance-free performance, bronze bushings will perfectly match your needs. Of course, you can also contact us to customize a mixed solution to balance cost and performance.

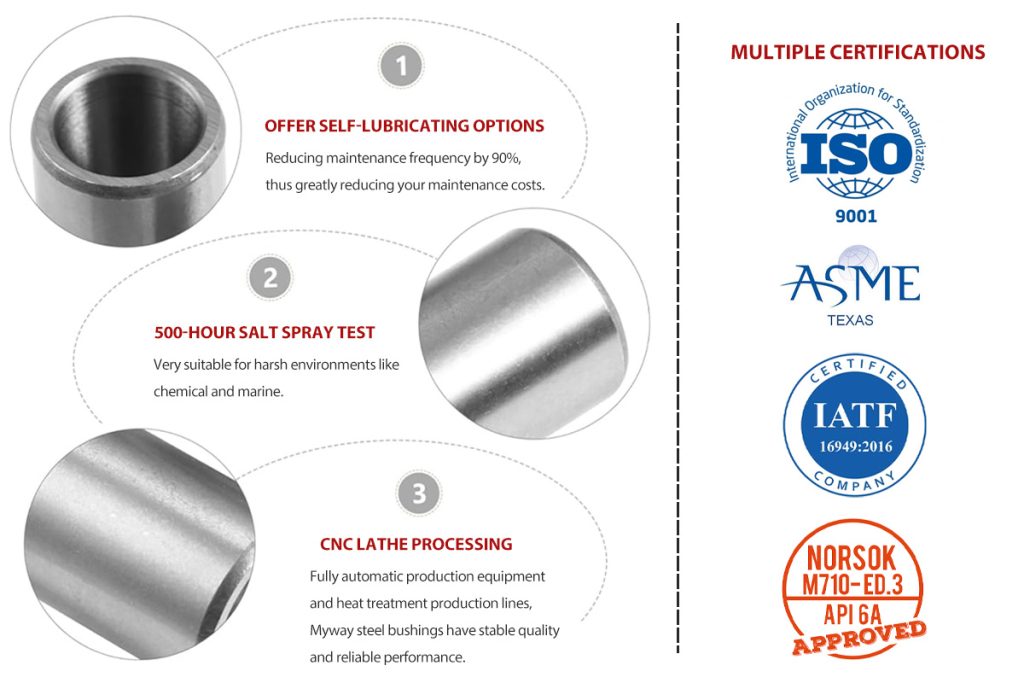

Why Choose Myway Steel Bushings

Myway steel bushings offer self-lubricating options, reducing maintenance frequency by 90%, thus greatly reducing your maintenance costs. Our stainless steel bushings has passed the 500-hour salt spray test, very suitable for harsh environments like chemical and marine.

With CNC lathe processing, fully automatic production equipment and heat treatment production lines, Myway steel bushings have stable quality and reliable performance. You can fully trust us, and our products have passed ISO9001, ASME, IATF 16949, API 6A and other international certifications.

Myway is a factory integrating design, production and testing, with multiple production lines and experienced technicians. We can guarantee delivery within 7 days and support global logistics. Choosing Myway means that you can buy high-quality bushings at an favorable price with short lead time.

Applications of Steel Bushings

Automobile

Steel bushings play a key mechanical connection role in the suspension system and gearbox of automobiles. Their wear resistance makes them perform well in high-load and high-frequency motion scenarios.

Marine

Thanks to the corrosion resistance of materials such as stainless steel and alloy steel, steel bushings can maintain stable performance in marine environments and meet the requirements of heavy support.

Aerospace

Landing gear systems and engine components in the aerospace field require precision steel bushings. Using it can improve the avoidance of various components being damaged by frequent friction and causing failures.

Industrial Equipment

Bushings are essential wear-resistant parts in industrial equipment such as excavators, crushers, and combine harvesters. It also demonstrates excellent performance in dusty environments.