Home » Agricultural Bearings

Myway Bushings for Agricultural Machinery

Durable Agricultural Bearings for Your Tractors, Harvesters & Seeders

- Having passed the ISO 9001 certification

- Self-lubricating properties reduce downtime

- Tolerant to -40℃ to 150℃ environments

- Full range of agricultural bushings for selection

- Compatible with major global agricultural machinery brands

What are the Common Types of Agricultural Machinery?

Tractors

Tractor, a high-powered, low-speed traction vehicle and power unit used for tilling, seeding, crop maintenance and harvesting. It is mechanically similar to a car or truck but is designed for off-highway use, reducing labor costs and increasing efficiency.

Combined Harvesters

The modern combine harvester, also known as a combine, is a machine used to harvest wheat, corn, soybeans, and other grains. The combine harvester is one of the most important labor-saving inventions in the economy, combining the functions of harvesting, threshing, and cleaning grain in one machine, greatly reducing the proportion of the population engaged in agriculture.

Plows

A plow is a practical tool for turning over the soil. It usually has multiple blades fixed to a frame in order to cover a larger area. Different types of tractor plows are available: Moldboard Plow, Reversible Garden Plow, Chisel Plows, Disc Plows, Sub-Soiling Plow.

Seeders

Seeders are a type of planting machinery. Seeders are very important to farmers because they help sow seeds to the desired depth by maintaining the required spacing. Seeders can also apply fertilizers during the sowing process.

Hay and Forage Harvesting Equipment

Harvesting equipment includes Self-Propelled Forage Harvesters, Rotary Harvesting Heads and Self-Propelled Forage Harvester Pickups. They are specially used for harvesting hay and fodder, and can also be used for lodging crops and other crops. It has two widths, single row and double row, suitable for high-density harvesting.

Agricultural Shredders

Agricultural crushers are specially used to crush agricultural waste, breaking crop straw, branches, weeds, vines and other organic materials into fine particles for easy recycling or environmentally friendly treatment. They are widely used in fields, orchards, forest farms and garden maintenance scenes.

Irrigators

Agricultural irrigation equipment (Agricultural Irrigators) ensures that crops get accurate water supply at different growth stages by scientifically regulating irrigation volume and time, and has become the core equipment for efficient use of water resources in modern agricultural production. It includes sprinkler irrigation systems, drip irrigation systems, micro-irrigation systems, intelligent irrigation systems, etc.

Disc Harrows

Disc harrow is an agricultural machine that cultivates the soil by rotating disc blades. It is mainly used to break up soil clods, level the surface and mix stubble. Its disc blade diameter is usually 460-660 mm, the tillage depth is 18-22 cm, and it can be used for heavy clay soil and wasteland reclamation.

Rotary Harrows

Rotary harrows break up the soil and finely level the soil using rotating teeth or blades, and are primarily used for seedbed preparation and weed control. The tips of the teeth have angled fins that spin to throw clods of soil against a notched baffle, where they are broken up into 10-20 mm particles.

Lawn Mowers

Using reel or rotary blade cutting technology, the mower uses highly rotating blades to cut grass stems. With the continuous development of technology, it is both environmentally friendly and intelligent.

Balers

Balers compress and bundle materials for efficient storage and transportation. There are two types of balers: square balers and round balers. John Deere’s 560 square baler can produce 120 bales per hour, with very high working efficiency.

Rice Transplanter

The rice transplanting machine is one of the core equipment of large-scale rice planting. It is a special agricultural machinery for rice transplanting. Through mechanized operation instead of traditional manual transplanting, it can improve the efficiency of transplanting and realize efficient and standardized transplanting of seedlings.

What Parts of Agricultural Machinery Require Bushings?

In agricultural machinery, bushings are widely used as key components in high-load, high-friction or precision-supported parts, and their performance directly affects the reliability and service life of the equipment. The following is a summary of the main parts that require bushings in agricultural equipment:

1. Tractor

- Transmission system: The gear shaft in the tractor’s gearbox needs bushing support to prevent direct metal friction during high-speed rotation. Bushings can also reduce the wear of the clutch engagement in the release bearing seat, driven plate spline hole and other parts to ensure smooth power transmission.

- Engine system: The camshaft of the engine needs bushings as support during high-speed reciprocating motion, and the piston and connecting rod also need bushings to connect. Its high wear resistance is very suitable for the harsh environment of the engine system.

- Suspension and steering system: The lifting arm and steering knuckle of the excavator are key components for suspension and steering. Plastic bushings and self-lubricating bushings can serve as fulcrums to reduce steering resistance and reduce maintenance.

- Auxiliary system: The starter shaft can maintain the accurate position of the oil hole under the action of the bushing. The engine bushing can greatly reduce wear and maintain the normal operation of the machinery.

2. Combine Harvester

- Cutting and conveying parts: The harvester’s lifting arm, conveyor chain and threshing drum all need bushings to reduce friction, vibration and noise.

- Adjustment and transmission parts: The drive shaft of the reciprocating cutter needs bushings to reduce impact, and bronze bushings with high mechanical strength are commonly used.

3. Seeder

- Seed metering system: Precision seeding requires seed spacing error ≤ Bushings can fix the position of parts and reduce the wear of parts during operation. If fertilization is required, it is necessary to use bushings with strong corrosion resistance, such as stainless steel bushings or ETFE coatings.

- Ditching and covering parts: The trencher bears soil resistance when entering the soil, and the self-lubricating bushing can reduce power loss and extend service life.

4. Baler

- Pickup and compression system: The baler picker speed reaches 200rpm, and it is necessary to use bushings with strong wear resistance.

- Bundling and wrapping parts: When the baler’s knotting frequency is as high as 120 times/minute, the bushing needs to be wear-resistant. You can use a graphite-inlaid bronze bushing, which can still maintain a friction coefficient of 0.15 in the case of insufficient lubrication and reduce the knotting failure rate by 20%.

5. Spraying and Plant Protection Machinery

- Sprayer boom and liquid pump system: The folding mechanism of the sprayer boom needs to withstand wind load and vibration, and the bushing needs to have both impact resistance, corrosion resistance and long service life. Stainless steel 316 bushings can meet your needs.

- Stirring and filtering parts: The shear force generated by the stirring of the liquid can easily cause the bushing to wear, so a coated bushing is essential, which has a service life 30% longer than that of an ordinary bushing.

Summary of Agricultural Machinery Brands

No matter what brand and model of your excavator, we can provide you with precision matching OEM parts to replace the bushing, which can reduce your procurement cost while ensuring performance. The brands of excavators we can provide replacement bushings include but are not limited to:

John Deere

CNH Industrial

Kubota

AGCO

Claas

Mahindra

Yanmar

LOVOL

ZOOMLION

- John Deere, headquartered in Moline, Illinois, USA, is a global pioneer brand of agricultural machinery and a technical benchmark in the industry. Its frozen pear system has achieved an output of 150 horsepower and has made major breakthroughs in the field of unmanned driving.

- CNH Industrial is an Italian agricultural machinery brand. It has high-end products in the Case IH Magnum series and economical products in the New Holland T7 series, accounting for 10.7% of the global agricultural machinery market share.

- Kubota was founded in 1890 and has a long history. Its engine technology has great advantages. For example, the horizontal diesel engine uses a TVCS combustion chamber, the cold start temperature is as low as 0℃, and the fuel consumption is reduced by 10%.

- AGCO‘s sprayer achieves intelligent spraying effects, can identify weeds through AI, and supports night operations, and the pesticide utilization rate is increased to 95%. Its Fendt 1000 Vario tractor has a power output of 400 horsepower and a transmission efficiency of ≥95%.

- Claas is a German agricultural machinery brand with a global market share of over 50% in forage harvesters. The biomethane-powered tractor prototype it developed reduces carbon emissions by 90% compared to diesel models and is scheduled to be mass-produced in 2026.

- Mahindra launched the CBG (compressed biogas)-powered Yuvo Tech+ tractor in 2024, reducing carbon emissions by 30%. It has a market share of over 40% in India and exports to 100+ countries.

- Yanmar has the largest market share in rice machinery in Southeast Asia, with a market share of over 25% in Thailand. Its V3307 Micro-Hybrid system reduces fuel consumption by 10% in paddy field operations.

- LOVOL is a Chinese agricultural machinery brand. It also has a large share in the international market, with products exported to 120+ countries. Its LOVOL GM80 harvester is equipped with Beidou navigation, and the wheat harvesting loss rate is ≤1.5%.

- ZOOMLION is also a well-known brand in China. Its ZOOMLION TB60 harvester is equipped with an AI vision system that can automatically identify crop maturity. The ZE200E electric excavator reduces carbon emissions by 100% compared to traditional models.

Common Agricultural Bearings for You

The structure of the self-lubricating bushing has three layers: steel backing layer, sintered copper powder layer and PTFE layer. The PTFE surface layer continuously releases lubricant, making its friction coefficient as low as 0.04~0.20, suitable for difficult-to-maintain parts such as gear shafts of gearboxes, transmission systems, harvesting systems, etc.

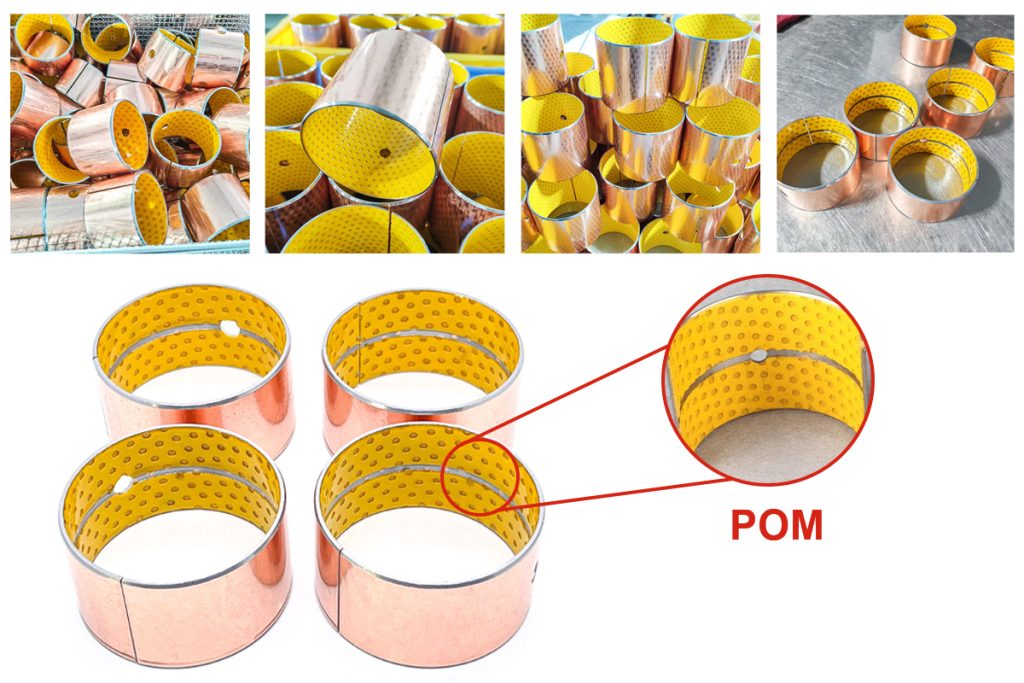

The difference between boundary lubrication bushing and self-lubricating bushing is that its inner layer is made of POM, with oil holes inside, and needs to be pre-lubricated with lubricating oil. The volume of the surface oil pit accounts for 15%-20%. It is suitable for use in transmission systems, suspension systems and power transmission systems.

Bronze bushings are made of tin bronze, aluminum bronze and high-lead tin bronze. Its hardness can reach HB120 and its tensile strength is ≥600MPa. In addition, it has super corrosion resistance and is suitable for engine systems, hydraulic systems and heavy machinery, etc. Its service life is twice that of steel bushings.

Steel bushings are usually made of carbon steel, stainless steel and alloy steel. The hardness of 40Cr steel bushings after quenching and tempering is HRC28~32, and they are often used as steering knuckle bushings. The press-fit interference is 0.03~0.06mm, and the compressive strength is ≥800MPa.

Plastic Bushings

Plastic bushings are made of polymers, polyoxymethylene and nylon. They are resistant to dirt and have low water absorption, and are widely used in maintenance-free applications such as lifting arms and adjustment mechanisms. POM bushings can work continuously in an environment of -40 to 100°C, making them an economical, efficient and corrosion-resistant choice.

Rubber Bushings

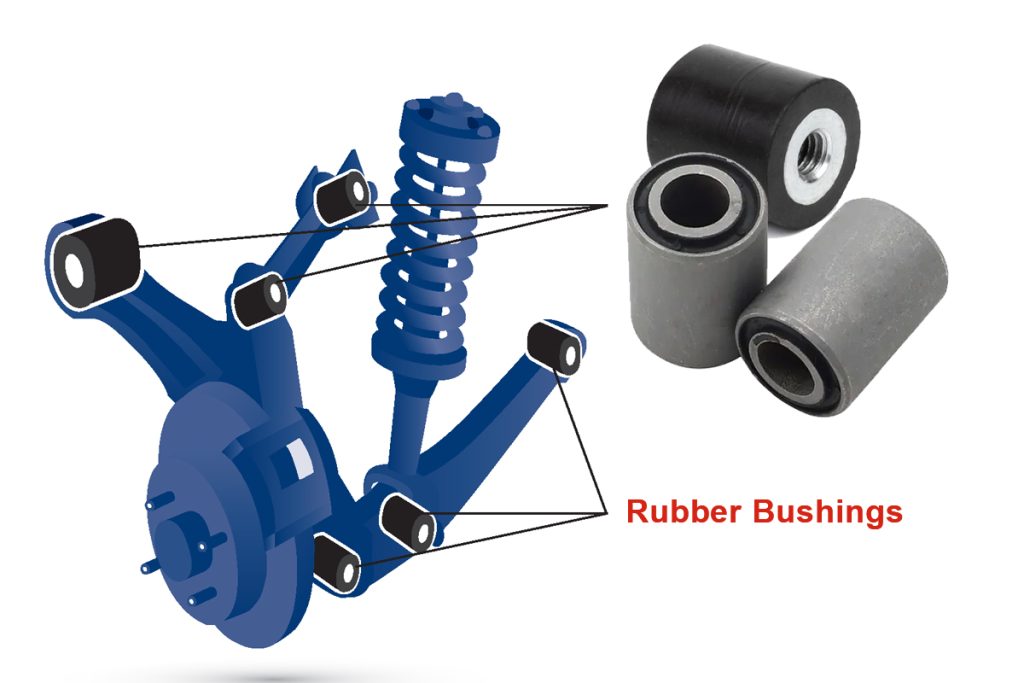

Rubber bushings are divided into natural rubber bushings, nitrile rubber bushings and EPDM bushings. It adopts a structure of metal skeleton, rubber elastomer and fabric reinforcement layer, with a torsional stiffness of ≥50N・m/°, and is widely used in suspension systems, harvesting machinery and power transmission components.

Factory Gallery

FAQs

Bushings are a type of sliding agricultural bearings, designed for low-speed, high-load farm machinery. They’re simpler, more durable, and cost-effective than rolling bearings in most agricultural applications.

Signs include: unusual noise in rotating parts, increased vibration, or visible wear (e.g., grooves in the bushing surface). Replace before they cause damage to shafts or housing.

Yes, we match 98% of common agricultural bearings housing dimensions (e.g., SAE J1960 standards).

Zhejiang Myway Co., Ltd. was established in 2005 and has grown into a leading company in the bushing industry. It has more than 20 years of experience in high-quality bushing research, development and production.

Copyright © 2025 Zhejiang Myway Co., Ltd. All Rights Reserved.

Quick Links

Address

Greenland Central Plaza, Gongshu District, Hangzhou City, Zhejiang Province, China