Page Structure Overview

Tractor Bushings Overview

Our tractor bushings are essential components for ensuring stable operation in agricultural machinery under heavy loads, muddy, and wet conditions. With superior wear resistance and self-lubricating features, these bushings are ideal for increasing equipment efficiency and minimizing downtime, making them a preferred choice for agricultural machinery manufacturers and parts suppliers.

Our tractor bushings are engineered to withstand harsh environments and are made from high-performance materials. They feature excellent wear resistance, corrosion resistance, and self-lubricating properties, making them suitable for various tractor models and agricultural equipment.

Key Benefits:

- Long-lasting wear-resistant materials

- Self-lubricating design for reduced maintenance

- High load capacity for heavy-duty operation

- Corrosion resistance for wet and muddy conditions

Product Types of Tractor Bushings

1 SF-1/DU Self-Lubricating Bushing

- Material: PTFE-based material for excellent self-lubrication.

- Best Use: Medium-speed, low-load applications like steering and suspension systems.

- Key Features: Reduces friction without extra lubrication, minimizing maintenance costs.

2 Bimetallic Bushing

- Material: Steel outer layer with a bronze inner layer for high strength.

- Best Use: High-load, long-duration operations in powertrains and suspensions.

- Key Features: High impact resistance, suitable for continuous operation.

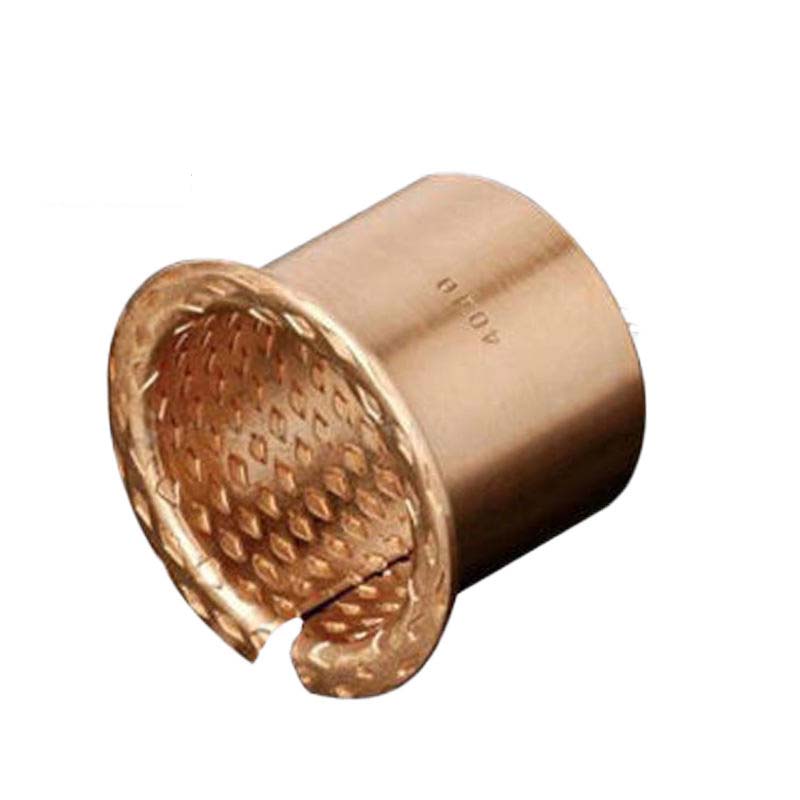

3 Bronze Bushing

- Material: High-strength bronze alloy with strong corrosion resistance.

- Best Use: Wet and corrosive environments like tractor chassis and suspension.

- Key Features: Extends equipment lifespan in humid and muddy conditions.

4 Embedded Graphite Bushing

- Material: Embedded solid lubricants (e.g., graphite) for improved lubrication.

- Best Use: High-temperature components, such as engine linkages.

- Key Features: Maintains stable performance in extreme temperatures.

Bushing Material Performance & Comparison

Material Type | Friction Coefficient | Max Load (N/cm²) | Temperature Range (℃) | Wear Resistance | Corrosion Resistance |

SF-1/DU | 0.04-0.20 | 140 | -195 to 280 | High | Medium |

Bimetallic | 0.10-0.25 | 250 | -40 to 200 | High | Low |

Bronze | 0.15-0.35 | 200 | -100 to 200 | Medium | High |

Embedded Graphite | 0.03-0.15 | 220 | -50 to 300 | High | Medium |

Brake Caliper Bushings Technical Specifications

| Picture | Application site | MW# | Replaces | Size | WT. | Fits | Brand |

| PIVOT PIN REAR | MW055 | L62836 | 45 x40 x 38mm | 0.21lbs | 820,830,840,920,930,940,1020,1030,1040,1120,1130,1850, 1950,2020,2030,2040,2040S,2120,2650,2850,3050,3150 | John Deere | |

| | SPINDLE | MW056 | T21539 | 38.2 x 35 x 38mm | 0.12lbs | 820,830,840,920,930,940,1020,1030,1040,1120,1130,1140,1350, EM14881550,1630,1640,1750,1840,1850,1950,2020,2120,2240 | John Deere |

| | SPINDLE | MW057 | L27821 | 41.4 x 38.3 x 37.9mm | 1020,1030,1040,1120,1130,1140,1550,1630,1640,1750,1830,1840, 1850,1950,2020,2030,2040,,2120,2130,2250,3030,3130 | John Deere | |

| | STEERING ARM | MW059 | L62839 | 52.5*41.5*57mm | 0.27lbs | 202,021,202,240 | John Deere |

| | DRIVE SHAFT | MW060 | L60747 | 36.5*32.41mm | 0.13lbs | 1550,1750,1850,1950,2250,2450,2650 | John Deere |

| | SMALL END | MW076 | R74008 | 47.593*52.37* 47.57mm | 985,985H4,1085,1085H4,1177,1188,1188H4,1450,1550,2056,2058, 2064,2066,4050,4055,4240S,4250,4255,4350,4450,4455,4555,4640, | John Deere | |

| | AXLE PIN | MW108 | 405570R1 | 50*47.5*53.5mm | 0.22lbs | 238,248,258,268,288,385,395,454,474,475,484,485,685XL,695,695XL, 784,785,785XL,795,884,885,3210,CX70,CX80,CX90,CX100 | Case-IH & David Brown |

| | ZF AXLE OUTER | MW063 | 81306C1 | 0.17lbs | (248,258,268,288,385,485,585,685,695,743,745,,785,795,844,845,856, 885,895,985,995,)(956,956XL,1056,1056XL-APL345) | Case-IH & David Brown | |

| Front axle | MW199 | 180345M1 | 31*35.5*38.5mm | 0.12lbs | Ferguson:TE20,TEA20,TO20,TO30,TO35;MF:35,135 | Massey Ferguson | |

| AXLE PIN BUSH STRAIGHT AXLE | MW209 | 1660114M1/888314M1 | 42.44*48.1*31.95mm | 0.23lbs | 133,135,145,148,152,155,158,230,235,240,250,255,260,550 | Massey Ferguson | |

| FRONT AXLE PIN BUSH | MW263 | C5NN3446A/81802940 | 35 x 31.9 x 37.9mm | 0.12lbs | 2000,2310,2600,2610,3000,3600, | Ford New Holland | |

| SPINDLE | MW299 | 5138179 | 42.2 x 38.0 x 39.8mm | 0.18lbs | 315,411,415,450,480,500,540,550,600,640 | Fiat | |

| SPINDLE/CENTER Axle-2 WD | MW300 | 5115656 | 42.2 x 38.0 x 39.9mm/40*43*2.5mm | 0.44lbs | 55-46,55-56,55-66,55-88,55-90,60-46,60-94,62-86,65-46,65-56, 65-94,70-56,70-66,70-76,72-86,72-93,80-76,80-88,80-90,88-94, 100-90,110-90,F100,F110,F115,F120,F130,F140,L60,L65,L75,L85,L95 | Fiat |

Learn more about gearbox bushings

If you want to find more information about the size, material or OEM number of transmission bushings, you can contact us. We have a lot of cooperation with transmission merchants in the Middle East

Performance Testing & Data

- Wear Resistance Test: Under simulated working conditions, SF-1 self-lubricating bushings can last for over 100,000 kilometers.

- High-Temperature Test: Embedded graphite bushings maintain stable friction coefficient and load capacity even at 300℃.

- Load Test: Bimetallic bushings showed no significant wear after 72 hours of continuous operation under heavy load conditions.

Typical Applications

Long-Haul Transport Trucks: Maintains stable wear resistance during prolonged high-speed operation, reducing maintenance frequency.

Engineering Vehicles: Performs exceptionally well in dusty and high-impact environments, making it suitable for long-term use.

Special Vehicles: Military and firefighting vehicles benefit from reliable, continuous self-lubrication under extreme conditions.

Customer Case Study

Custom Services and Solutions

Customization & Support Services

- Multiple Customization Options: Tailor materials, dimensions, and designs to meet specific customer needs, ensuring optimal compatibility.

- Professional Technical Support: Provides selection advice, installation guidance, and on-site technical consultations to help customers optimize performance.

- Fast Delivery: Robust supply chain and logistics services ensure timely delivery, reducing the risk of customer downtime.

Free consultation

Communicate with us to clarify the requirements

Free

design

Customize your product according to your needs

Sample

making

Confirm the drawings and arrange for sampling

Sample Confirmation

Customer confirms sample and arranges production

Finished inspection

Inspect the finished product and arrange for shipment

FAQ

Q: What is the lifespan of these bushings?

A: Depending on the material and operating conditions, the lifespan generally ranges from 5-10 years.

Q: What is the delivery time?

A: Standard models are typically shipped within 7-10 working days, while custom products depend on specific requirements.

Q: Do you offer samples?

A: Yes, we provide samples for testing purposes.

Q: What are the main advantages of self-lubricating bushings in truck brake systems?

A: Self-lubricating bushings reduce friction and wear without the need for additional lubrication. This minimizes maintenance frequency, improves braking efficiency, and increases the overall lifespan of the braking system. They are particularly useful in environments where frequent lubrication is impractical.

Q: How do I choose the right bushing material for my truck's braking system?

A: The right material depends on several factors, including load capacity, operating temperature, environmental conditions (e.g., moisture, dust, or corrosion), and maintenance needs. For example:

- SF-1 Self-Lubricating: Ideal for medium-speed, low-load applications.

- Bimetallic: Best for heavy-load, high-impact conditions.

- Bronze: Suitable for wet or corrosive environments.

- Embedded Graphite: Performs well under high-temperature and high-frequency braking.

Q: Are your bushings compatible with all types of heavy-duty trucks?

Q: What is the difference between your standard bushings and custom-made bushings?

A: Standard bushings are manufactured in common sizes and materials to suit general applications. Custom-made bushings can be tailored in terms of dimensions, materials, surface treatments, and load capacities, providing optimized solutions for specific operational conditions.

Q: How should I maintain these bushings for optimal performance?

A: Although self-lubricating bushings require less maintenance, regular inspections are recommended to check for wear, debris buildup, or damage. In heavy-duty or corrosive environments, occasional cleaning may be necessary to maintain optimal performance.

Q: Do you offer bushings that comply with international safety and quality standards?

A: Yes, all our bushings are manufactured in compliance with ISO 9001 and TS 16949 quality management standards. They also meet relevant industry safety and performance regulations.

More Related Bushing products

Quick Quote & Customization

Want to learn more about our brake caliper bushings? Click the button below for a customized quote or technical consultation!

Tel/Whatsapp: +86 136 4583 4002

Email:myway@mybushing.com