Myway Truck Bushings

All Types of Bushings for Your Light, Medium or Mid-duty Trucks

- Suitable for a variety of truck models, easy installation.

- Prolong service life of truck parts, reduce maintenance costs.

- Reduce vibration and noise, improve driving comfort.

- Excellent high temperature resistance and oil pollution resistance .

- Self-lubrication design, maintenance free and environmentally friendly.

- Available with metal, polyurethane and rubber bushings

What are the Common Types of Trucks?

Trucks are categorized by load capacity into 3 types: light, medium, and heavy. These 3 load capacity ranges correspond to completely different transportation scenarios, technical designs, and industry values. The following is an introduction to trucks:

- Light Trucks: Pickup trucks, box trucks, trailers, specialized trucks, furniture trucks, and snowplows.

Light trucks typically have a gross weight between 1.8 and 6 tons, a length of 6 meters or less, and a flat-top cab, making them easy to navigate narrow city streets and residential alleys. They come in a variety of cargo bed styles, including flatbed, box trucks, and shed trucks. Some models have been upgraded to pure electric drive, offering a range of 150-300 kilometers.

- Medium Trucks: Box trucks, ship transport trucks, cement trucks, fire trucks, crane trucks, maintenance trucks, livestock trucks, and flatbed trailers.

Medium trucks typically have a gross weight between 6 and 14 tons, a cargo bed length of 6.8 to 8.6 meters, and can carry 8 to 12 tons of cargo.

They offer greater cargo capacity than light trucks and greater flexibility than heavy trucks. They are commonly used for cargo transfer between cities and surrounding counties, transporting agricultural products, and delivering construction materials to small and medium-sized construction sites. Transport distances are generally within 300 kilometers.

- Heavy-duty Trucks: Semi-trailer trucks, Australian road trains, tractor trailers, car transporters, tankers, and logging trucks.

Heavy-duty trucks have a gross vehicle weight of at least 16 tons and a length of at least 9 meters. They are attached to a semi-trailer via a saddle and are the workhorse of long-haul trunk logistics. They can pull up to 49 tons. They are typically equipped with a large-displacement diesel engine, a multi-speed transmission, and air suspension.

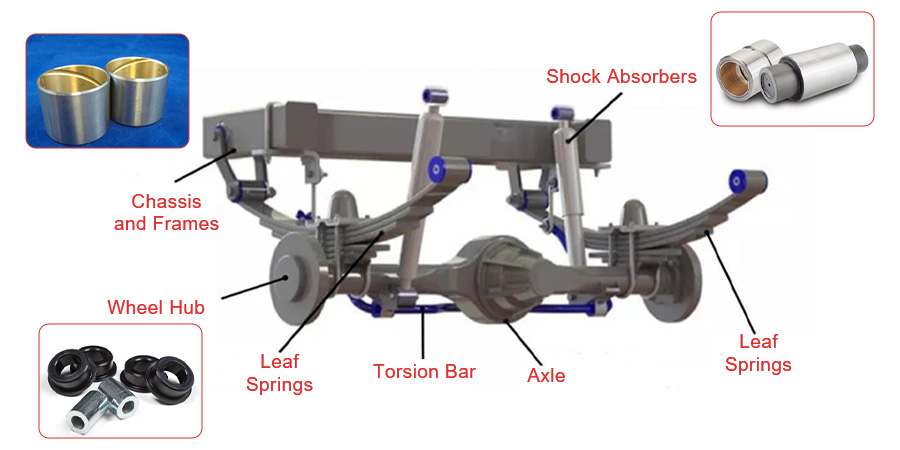

What Parts of Trucks Require Bushings?

In a truck’s complex mechanical systems, bushings are critical components, widely used to connect moving parts, cushion vibrations, and transfer loads. Their core function is to absorb shock through elastic deformation, reduce metal-to-metal friction, and ensure precise positioning between components.

The following is an introduction to the key areas in a truck where bushings are needed:

1. Suspension System

- Leaf Spring Lifter Bushings

Bushings are located in the lifting lug holes that connect the leaf spring to the vehicle frame. Because they need to absorb road shock and allow the lifting lugs to oscillate freely as the spring deforms, bushings are typically made of wear-resistant rubber or polyurethane.

Their inner bores provide an interference fit with the pins, while the outer vulcanized metal framework provides increased support and prevents direct impact between the leaf spring and the frame.

- Shock Absorber Bushings

At the junctions between the upper and lower ends of a vehicle’s shock absorber and the vehicle frame, bushings isolate the shock absorber piston rod from high-frequency vibrations.

Typically, double-layer rubber-to-metal bushings are used to protect the shock absorber from excessive bending moments, extending its service life by 40%.

- Control Arm Bushing

Control arm bushings are located at the junction of the control arm and the vehicle frame or steering knuckle in an independent suspension system.

They allow the control arm to swing freely in the vertical plane and absorb lateral forces, preventing frame deformation. The bushings are constructed with a self-lubricating nylon layer with a coefficient of friction of ≤0.15, reducing metal-to-metal wear.

- Stabilizer Bar Bushing

The stabilizer bar bushing is located at the junction of the lateral stabilizer bar and the lower control arm. It effectively suppresses vehicle roll, buffers torsional stress in the stabilizer bar, and prevents metal fatigue fracture.

It features a split clamp design for easy installation and adjustment. Made of EPDM rubber, it is ozone- and weather-resistant for over 10 years.

2. Steering System

- Tie Rod Bushing

The tie rod bushing contains a spherical rubber bushing that allows 360° rotation. It transmits steering torque from the steering wheel to the wheels and compensates for temperature-related length expansion and contraction of the steering rod. A metal dust cover ensures a good seal and prevents the ingress of impurities.

- Idler Arm Bushing

The idler arm bushing is located at the fulcrum between the steering drop arm and the vehicle frame. It supports the pivoting movement of the steering idler arm, maintaining a stable toe angle of the front wheels, ensuring a deviation of no more than 0.5° and minimizing tire wear. Self-lubricating bushings are recommended for maintenance-free operation and reduced downtime.

- Rack Bushing

Racks typically use PTFE composite bushings to reduce frictional resistance in the rack’s reciprocating motion and absorb road shock. Located on the sliding contact surface between the steering rack and the housing, the bushing has an inner surface roughness of Ra ≤ 0.8μm, reducing sliding resistance to below 0.5N/mm.

3. Transmission System

- Driveshaft Bushings

The driveshaft’s mid-section requires bushings at its connection to the vehicle frame to support the shaft’s weight and compensate for axial play caused by engine vibration. Rubber-metal composite bushings can be used, and some models also use rolling bearings to reduce friction losses during high-speed rotation.

- Transmission Bushings

The transmission’s end is connected to the vehicle frame, exposing it to the risk of housing bending moments. Bushings play a significant role here, reducing the risk of cracking by over 60% and isolating the impact of engine vibration on the transmission gears. You can use rubber main spring metal bushings to reduce vibration transmission to 1/3 of the original system.

- Differential Bushings

The differential case and rear axle housing require bushings as a buffer. They effectively reduce torque fluctuations in the differential gears and maintain the coaxiality of the differential axis with the driveshaft. High-damping rubber bushings are generally sufficient. For extreme operating conditions, such as in mining, sintered metal bushings are preferred.

Summary of Trucks Brands

Scania

Volvo

Mercedes-Benz

MAN

IVECO

Freightliner

Kenworth

Peterbilt

Mack

ISUZU

Hino

FAW Jiefang

Dongfeng

Chevy

Ford

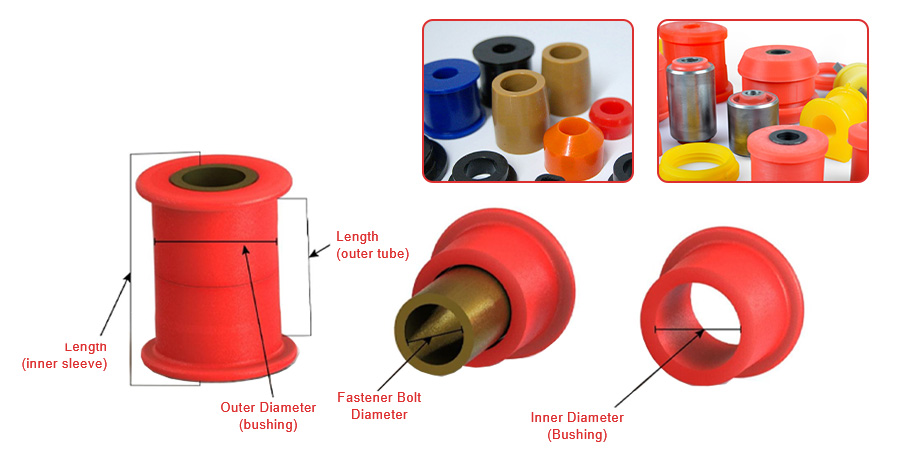

Track Bushings Types for You

Rubber Bushings

Rubber bushings are commonly used in truck suspension and transmission systems, absorbing 80% of road impact and reducing noise. Available materials include natural rubber, nitrile rubber, and EPDM. Compared to other materials, rubber bushings offer advantages such as low cost, easy installation, and adaptability to complex motion paths.

Natural rubber has an elastic modulus of 3-8 MPa and is suitable for use in environments ranging from -40°C to 60°C. Nitrile rubber can withstand temperatures up to 90°C and offers excellent oil resistance, 30% higher than standard rubber. EPDM also offers excellent resistance to ozone aging. You can choose the appropriate rubber bushing based on your application needs.

Polyurethane Bushings

Polyurethane bushings are 30%-50% harder than rubber bushings, offering 2-3 times greater wear resistance, making them suitable for use in high-wear environments, such as those under heavy loads or in construction trucks. High-hardness polyurethane can achieve a tear strength of up to 30 MPa. Furthermore, self-lubricating polyurethane bushings infused with PTFE particles reduce maintenance requirements.

Polyurethane bushings are available in two structures: a segmented hardness design with inner and outer layers of rubber of varying hardness; and a honeycomb-shaped inner pore design, which increases contact area by 30% and improves heat dissipation efficiency by 40%.

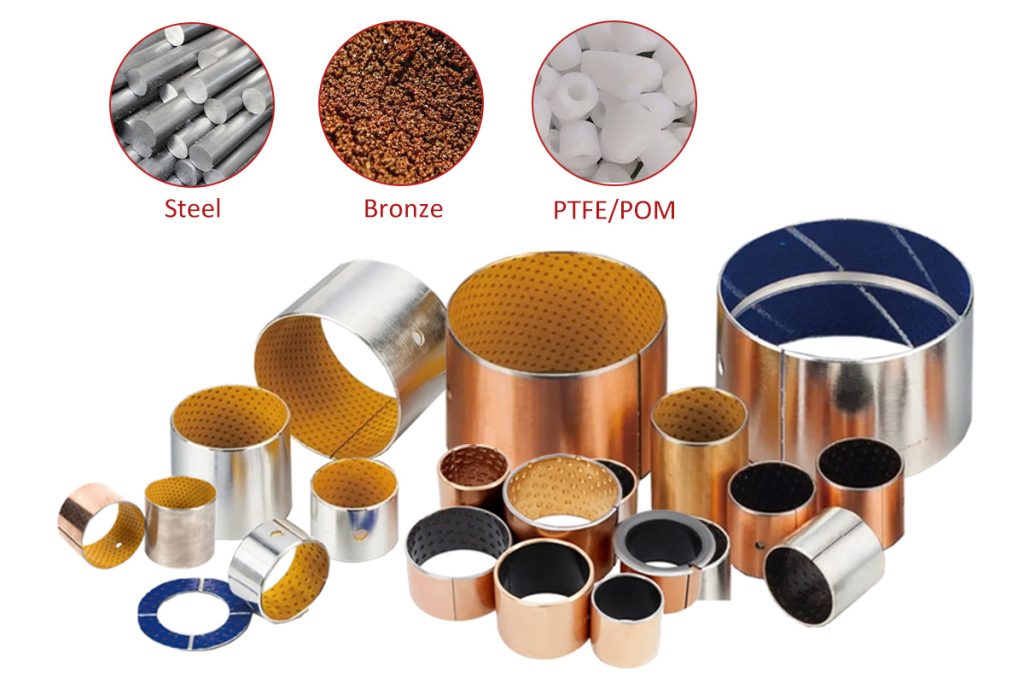

Self-lubricating bushings consist of three layers: an inner PTFE lubricating layer, a middle sintered copper powder layer, and an outer steel plate layer. They offer excellent temperature resistance, withstanding temperatures as high as 150°C while maintaining low friction even at -30°C cold starts. This makes them ideal for truck braking and suspension systems.

With a dynamic load capacity of 250 MPa and a static load capacity of 400 MPa, self-lubricating bushings offer significantly greater load-bearing capacity than rubber bushings. Furthermore, they have passed salt spray tests and exhibit excellent corrosion resistance, making them suitable for use in transport vehicles in coastal areas.

Metal Bushings

Metal bushings are made from a variety of high-purity metals and alloys, including 304/316 stainless steel, bronze, carbon steel, and high-strength brass. They are suitable for low-speed, extreme operating conditions, high-precision requirements, and extremely heavy loads.

Bimetallic composite bushings feature a low-carbon steel outer layer for high mechanical strength and a sintered copper alloy inner layer for improved wear resistance, specifically designed for truck clutch applications. Spherical metal bushings can compensate for installation errors of ±2°, extending the service life of truck components.

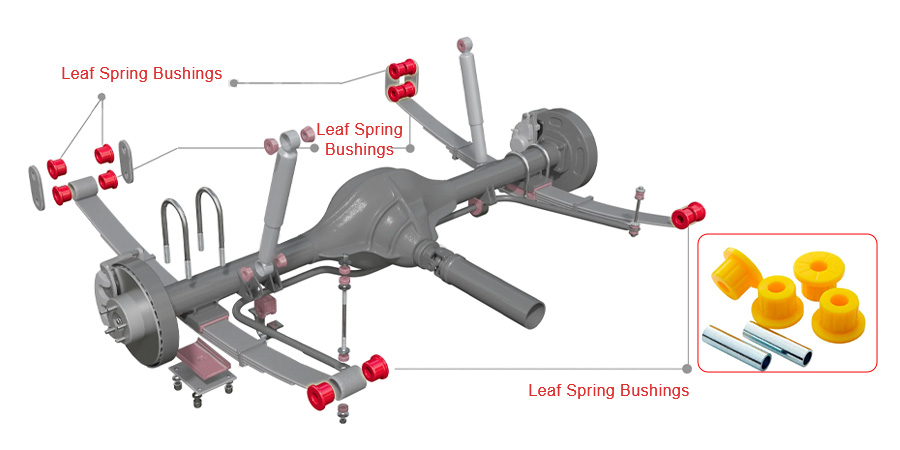

Leaf Spring Bushings

Spring bushings are specialized components in truck suspension systems. These cylindrical or sleeve-shaped assemblies are typically installed at the ends or mounting points of leaf springs, serving as shock absorbers that connect the spring to other vehicle parts.

Depending on load requirements and operating conditions, spring bushings are often made from rubber with excellent damping properties, or materials like polyurethane that offer superior durability, wear resistance, heat tolerance, and chemical corrosion resistance.

Factory Gallery

FAQs

- Unusual noises: A metallic grinding or creaking sound is heard while driving (especially when going over speed bumps or turning). This is often caused by metal-to-metal contact due to bushing wear.

- Increased vibration: Noticeable shake in the cab or steering wheel, or increased body roll (for example, when cornering with a heavy vehicle, the angle of lean is greater than before). This may indicate a failure in the suspension bushing’s elasticity.

- Visual abnormalities: If the bushing is cracked, the hardened polyurethane is peeling off, or the metal bushing is scratched or deformed, replacement is necessary.

Note: Ignoring these symptoms can lead to excessive wear of associated components (such as leaf springs and control arms), increasing repair costs by over 30%.

- Rubber Bushings: Approximately 80,000-120,000 kilometers for ordinary road transport (light load); reduced to 50,000-80,000 kilometers for frequent heavy-load or mountain road operation.

- Polyurethane Bushings: More wear-resistant, they can be extended to 150,000-200,000 kilometers for road transport and approximately 100,000-120,000 kilometers for harsh operating conditions such as mining.

- Metal/self-Lubricating Bushings: Approximately 60,000-80,000 kilometers for extreme operating conditions such as mining and construction vehicles; up to 150,000-200,000 kilometers for long-distance trunk transport (light load).

Note: The above standards are based on general cases. If the symptoms mentioned in question 1 occur, or if the bushing clearance exceeds 0.5mm (can be moved with a finger) during inspection, it should be replaced even if the bushing is not due.

Bushing replacement may seem simple, but improper handling can easily backfire.

We do not recommend replacing suspension bushings yourself. This requires a special press-fit tool. Using a regular hammer to forcefully hit the bushings can cause deformation or wear in the mounting holes, leading to unusual noises later.

Key points to keep in mind when replacing bushings:

- Before installation, clean any remaining debris from the old bushing (especially metal debris), as this will accelerate wear on the new bushing.

- Avoid contact of rubber bushings with engine oil or diesel (use soapy water for cleaning).

- Urethane bushings require a special silicone-based grease when installing (do not use butter, as it will corrode the material).

Zhejiang Myway Co., Ltd. was established in 2005 and has grown into a leading company in the bushing industry. It has more than 20 years of experience in high-quality bushing research, development and production.

Copyright © 2025 Zhejiang Myway Co., Ltd. All Rights Reserved.

Quick Links

Address

Greenland Central Plaza, Gongshu District, Hangzhou City, Zhejiang Province, China