MYWAY Wrapped Steel Bushing / Spring Steel Bushing

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Wrapped Steel Bushing

Wrapped Steel Bushing / Spring Steel Bushing

What is Wrapped Steel Bushing?

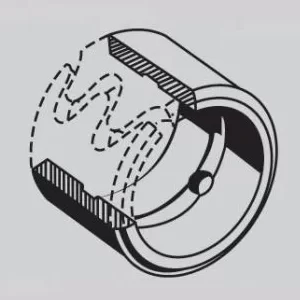

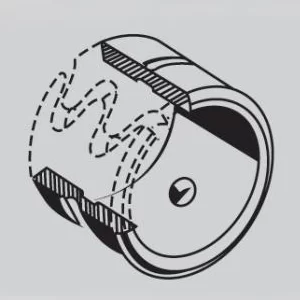

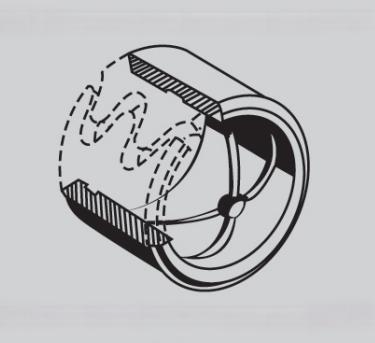

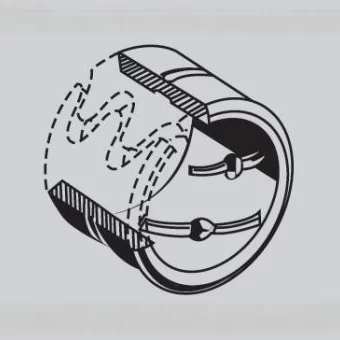

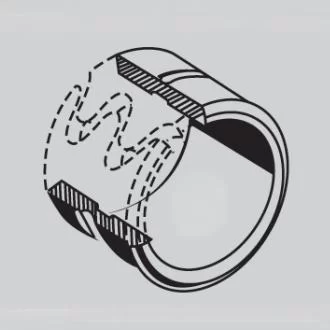

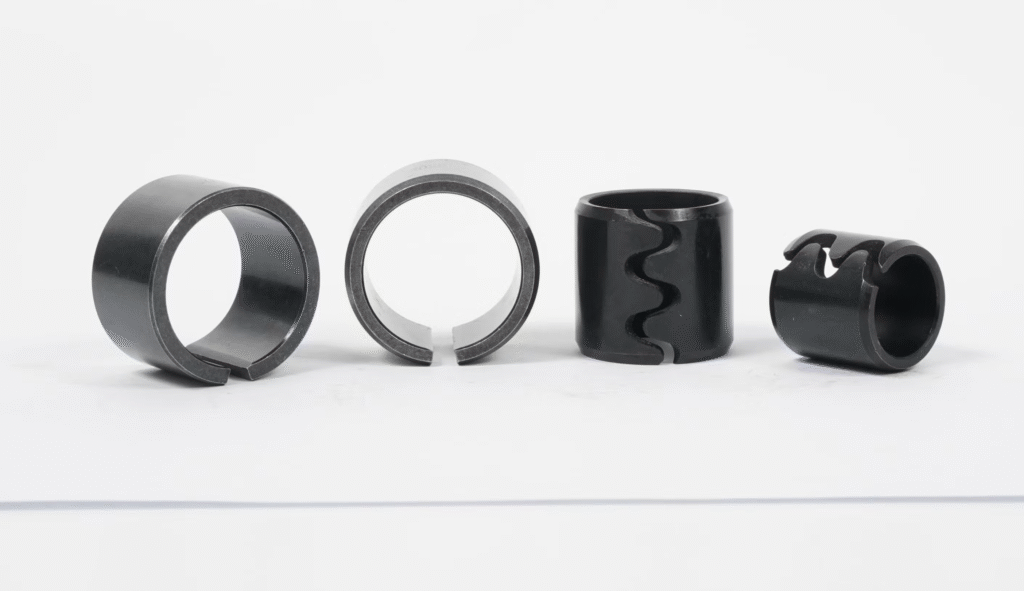

Wrapped Steel Bushings are manufactured from spring steel strips that are rolled and then subjected to through hardening and internal grinding. Designed to replace conventional bearing steel bushings, they offer moderate hardness, high load capacity, and excellent wear resistance. Their inherent elasticity provides a buffering effect that protects the shaft under heavy impact.

Compared to similar international products, our bushings feature a more scientific seam design for easier assembly and positioning, allowing full use of their elastic properties. Once pressed into the housing, the bushing remains securely held by its own elasticity. The internally ground bore ensures high dimensional accuracy. During operation, the bushing can self-adjust under high friction, preventing seizure and prolonging service life while safeguarding associated equipment.

Wrapped Steel Bushings by Structure

Wrapped Steel Bushings by Material

Wrapped Steel Bushings by Type

Wrapped Steel Bushings by Feature

Which Specification Do You Need?

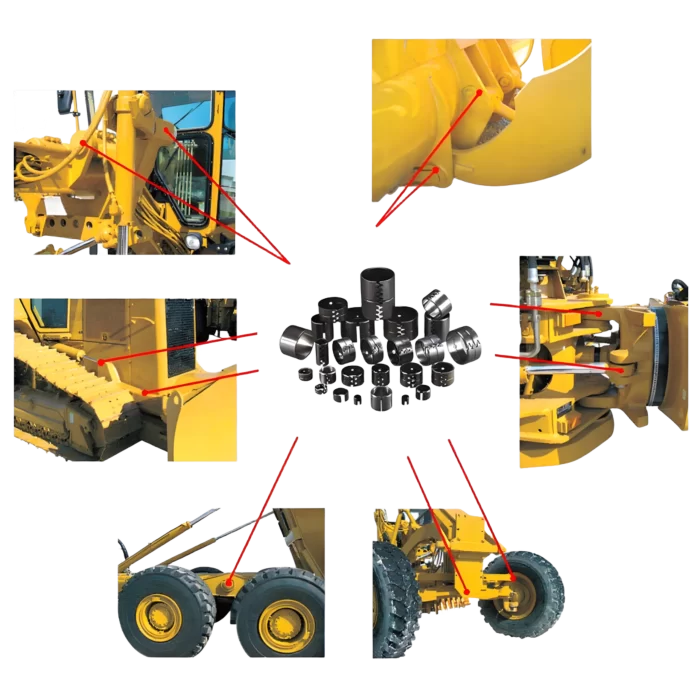

Applications of Wrapped Steel Bushing

Spring Steel Bushing: The Ultimate Guide to High-Performance Applications

Introduction to Spring Steel Bushings

In the world of industrial components, spring steel bushings represent a significant advancement in bearing technology. These specialized components are engineered to deliver exceptional performance under demanding conditions where traditional bushings often fail. But what exactly are spring steel bushings, and why have they become increasingly vital across numerous industries?

Spring steel bushings, also known as wrapped steel bushings, are precision components manufactured from high-quality spring steel plates that undergo specialized heat treatment and forming processes. Unlike conventional bushings, these components leverage the inherent elasticity of spring steel to create a durable, resilient bearing surface that can withstand significant dynamic loads, impacts, and varying operational conditions. This unique combination of properties makes them ideal for applications ranging from automotive suspensions to heavy machinery and aerospace systems.

The fundamental structure of a spring steel bushing typically consists of a rolled composite with a steel base, often featuring intermediate layers such as sintered bronze powder, and a surface treatment or coating that enhances its wear resistance and lubrication properties. This sophisticated construction allows these bushings to offer superior performance compared to traditional solid or plain bushings, particularly in applications involving rotation, oscillation, and high-impact loads .

Table: Comparison of Spring Steel Bushings vs. Traditional Bushings

| Property | Spring Steel Bushings | Traditional Bushings |

|---|---|---|

| Load Capacity | High (up to 250N/mm² static) | Moderate |

| Impact Resistance | Excellent due to inherent elasticity | Limited |

| Wear Resistance | Superior with proper surface treatment | Varies with material |

| Corrosion Resistance | Can be enhanced with plating/coating | Dependent on base material |

| Maintenance Requirements | Low (often self-lubricating) | Regular lubrication needed |

Key Characteristics and Advantages

Exceptional Load-Bearing Capacity

One of the most significant advantages of spring steel bushings is their remarkable load-bearing capability. Thanks to their unique construction and the material properties of spring steel, these bushings can withstand static loads up to 250N/mm² and dynamic loads up to 140N/mm² . This high load capacity makes them suitable for even the most demanding applications where heavy loads and high pressures are common.

The quenching and rubbing techniques used in the manufacturing process enhance the surface hardness and durability of the bushings while maintaining the flexibility of the core material. This combination creates a component that can handle substantial pressure without permanent deformation, ensuring long-term reliability and consistent performance throughout its service life.

Superior Wear Resistance and Longevity

Spring steel bushings are specifically engineered to offer exceptional wear resistance, significantly extending their service life compared to conventional alternatives. The surface of these bushings can be treated through various methods, including grinding, coating, or plating with materials like cadmium or other protective substances . These treatments reduce friction and minimize wear, even in applications with continuous movement or oscillation.

The precise tolerance ranges achieved through grinding processes ensure perfect fitment and optimal performance. When pressed into their housing, these bushings maintain their dimensional stability, preventing premature wear caused by improper alignment or loose fittings. This attention to precision manufacturing translates to reduced maintenance requirements and longer intervals between replacements, ultimately lowering the total cost of ownership for equipment manufacturers and operators.

Outstanding Impact Absorption

The innate elasticity of spring steel gives these bushings exceptional ability to absorb and dampen impacts . In applications where equipment subjects components to sudden shocks or vibration, this characteristic becomes invaluable. Unlike rigid bushings that might transfer these forces directly to adjacent components, spring steel bushings act as a buffer, protecting both the shaft and the surrounding machinery from damage.

This anti-occlude performance ensures that even under significant friction forces, the bushing can adjust its position slightly to distribute stress evenly. This self-adjusting capability prevents localized wear points and eliminates the risk of seizure—a common failure mode in less sophisticated bearing solutions. The result is enhanced equipment protection and reduced downtime due to component failure.

Applications Across Industries

Automotive and Transportation

The automotive industry extensively utilizes spring steel bushings in various critical applications. From suspension systems and shock absorbers to door hinges and seating mechanisms, these components provide the durability and reliability necessary for automotive safety and performance. Their ability to absorb road shocks and vibrations contributes significantly to vehicle comfort and handling.

In commercial vehicles and heavy-duty trucks, spring steel bushings are particularly valuable in leaf spring assemblies and kingpin applications . Here, they withstand tremendous static and dynamic loads while providing smooth articulation for steering and suspension movements. The wear resistance and low maintenance requirements of these bushings make them ideal for these safety-critical applications where reliability is paramount.

Agricultural and Construction Machinery

Agricultural and construction equipment operates in some of the most challenging environments, with exposure to heavy loads, shock impacts, dirt, moisture, and variable temperatures. Spring steel bushings excel in these conditions, providing reliable performance in applications such as tractor implements, harvesting equipment, excavator joints, and loader linkages.

The self-lubricating variants of these bushings are particularly beneficial in agricultural applications where regular maintenance may be challenging, and contamination from dirt or debris is likely. Equipment manufacturers can design machinery with longer service intervals and reduced lubrication points, lowering operating costs for farmers and construction companies while maintaining equipment reliability and uptime.

Industrial Machinery and Automation

In industrial settings, spring steel bushings find applications in various machinery including printing presses, textile machines, hydraulic systems, and material handling equipment . Their precision, durability, and ability to operate with minimal maintenance make them ideal for these often continuous-operation environments where unexpected downtime can be costly.

The precision-ground inner surfaces of these bushings ensure accurate movement and positioning in automated equipment, while their high load capacity allows for compact designs without sacrificing performance. This combination of characteristics enables machinery designers to create more efficient, reliable, and space-conscious equipment for modern manufacturing facilities.

Aerospace and Defense Applications

The aerospace and defense sectors demand components that offer exceptional reliability, precise performance, and the ability to function in extreme conditions. Spring steel bushings meet these rigorous requirements, finding use in various aircraft control systems, landing gear mechanisms, and military vehicle applications .

In these critical applications, bushings must often comply with specific standards and certifications. The manufacturing processes for spring steel bushings allow for the strict quality control and documentation necessary for aerospace and defense applications. Additionally, the ability to manufacture bushings from specialty steels or with specific coatings makes them suitable for the unique environmental challenges encountered in aerospace operations.

Design and Manufacturing Considerations

Material Selection and Specifications

The performance of spring steel bushings begins with proper material selection. While the base material is typically high-carbon or alloy spring steel, specific applications may require variations in composition or heat treatment to achieve the desired properties. The steel must possess the necessary elasticity, hardness, and fatigue resistance to perform reliably in its intended application .

For specialized applications, manufacturers may employ stainless steel variants such as 304 or 316 stainless steel for enhanced corrosion resistance . Other material options include various plating or coating materials that can improve surface properties, reduce friction, or enhance compatibility with specific operational environments. Understanding the application requirements is essential for selecting the optimal material combination.

Manufacturing Processes and Quality Control

The manufacturing of spring steel bushings involves several precise processes, each critical to the final performance of the component. These typically include material cutting, forming or wrapping, heat treatment, surface grinding, and any necessary plating or coating operations. The specific processes employed depend on the bushing design, material, and application requirements.

Quality control throughout the manufacturing process is essential to ensure consistent performance and reliability. This includes dimensional verification, material certification, hardness testing, and surface finish measurements. Many manufacturers adhere to international quality standards such as IATF 16949:2016 for automotive applications or specific industry standards relevant to their customers’ industries .

Technical Design Parameters

Engineers specifying spring steel bushings must consider several key technical parameters to ensure optimal performance:

Load Requirements: Both static and dynamic load capacities must be evaluated against application demands.

Operating Environment: Temperature range, presence of contaminants, and potential corrosion factors must be considered.

Movement Type: Whether the application involves rotation, oscillation, or linear motion affects bushing selection.

Speed Considerations: Surface speed limits must be respected to prevent premature wear.

PV Values: The relationship between pressure and velocity must remain within specified limits for proper operation.

Table: Technical Specifications of Spring Steel Bushings

| Parameter | Typical Range | Notes |

|---|---|---|

| Static Load Capacity | ≤ 250 N/mm² | Dependent on material and design |

| Dynamic Load Capacity | ≤ 140 N/mm² | At low speeds |

| Oscillation Load Capacity | ≤ 60 N/mm² | For rotational oscillation applications |

| Max Speed (Dry) | 2.0-2.5 m/s | Varies with lubrication conditions |

| Friction Coefficient | 0.03-0.25 | Depends on lubrication and surface treatment |

| Temperature Range | -200°C to +280°C | Varies with specific materials |

Why Choose MYWAY Spring Steel Bushings?

Uncompromising Quality and Precision

At MYWAY, we specialize in the manufacture of high-performance spring steel bushings that exceed industry standards. Our products leverage advanced manufacturing techniques and strict quality control processes to ensure consistent performance and reliability in even the most demanding applications. Each bushing undergoes rigorous inspection to verify dimensions, material properties, and surface characteristics.

Our proprietary heat treatment processes optimize the material structure of our bushings, creating the perfect balance between surface hardness for wear resistance and core flexibility for impact absorption. This attention to detail throughout the manufacturing process results in bushings that deliver longer service life, reduced maintenance requirements, and enhanced equipment performance for our customers.

Customized Solutions for Your Specific Needs

Understanding that each application presents unique challenges, MYWAY offers comprehensive customization options for our spring steel bushings. We can tailor various aspects of the bushing to meet your specific requirements, including:

Material selection from a range of spring steel grades and stainless steels

Custom dimensions and tolerances to match your design specifications

Specialized surface treatments and coatings for enhanced performance

Variations in bushing design including cylindrical, flanged, or thrust washer configurations

Our engineering team works closely with customers to understand their application challenges and recommend the optimal bushing solution. This collaborative approach ensures that you receive components that not only fit your equipment but also enhance its performance and reliability.

Competitive Advantage Through Technical Excellence

MYWAY spring steel bushings incorporate several proprietary design features that set them apart from conventional offerings:

Optimized interface design that facilitates easier assembly and more effective performance

Enhanced elasticity characteristics that provide superior impact protection for shafts and equipment

Precision grinding processes that ensure exact tolerances for optimal fit and function

Advanced surface technologies that reduce friction and wear without compromising load capacity

These technical advantages translate to tangible benefits for our customers, including reduced downtime, lower maintenance costs, and improved equipment performance. By choosing MYWAY as your bushing supplier, you invest in components that deliver value throughout their service life.

Global Standards Compliance and Certification

MYWAY spring steel bushings are manufactured in facilities that comply with international quality standards, including IATF 16949:2016 for automotive applications. Our products meet or exceed relevant industry specifications, ensuring compatibility and performance in global markets. We maintain comprehensive documentation and traceability for all our components, providing our customers with confidence in the quality and reliability of our products.

Choose MYWAY for Your Spring Steel Bushing Requirements

When your equipment’s performance depends on the quality and reliability of its components, trust MYWAY to deliver spring steel bushings that exceed expectations. Our technical expertise, manufacturing capabilities, and commitment to quality make us the ideal partner for your bushing requirements across industries.

Contact MYWAY today to discuss your specific application needs, request technical specifications, or obtain pricing information. Our engineering team is ready to provide the technical support and product recommendations you need to optimize your equipment’s performance with our high-quality spring steel bushings.

Visit our website or call our technical sales team to discover the MYWAY difference in spring steel bushing technology.

MYWAY Wrapped Steel Bushing FAQs

1. What are the characteristics of wrapped steel bushings?

Wave-form seam design offers self-adaptability to housing bores during assembly, reducing requirements for machining accuracy and lowering overall equipment costs.

Inherent elasticity simplifies installation and ensures a secure fit.

High hardness provides excellent wear resistance and extended service life.

Made from high-strength spring steel, these bushings support heavy loads and perform well under harsh conditions such as low speed and high load.

Self-adjusting capability under high friction helps prevent seizure, protects the shaft, and minimizes equipment damage.

2. What are the primary advantages of spring steel bushings over traditional bronze bushings?

Spring steel bushings offer several advantages over traditional bronze bushings, including higher load capacity, better impact resistance due to inherent elasticity, superior wear characteristics through specialized surface treatments, and often reduced maintenance requirements. The composite structure of many spring steel bushings allows for optimized performance characteristics that surpass what can be achieved with a single material .

3. Can spring steel bushings operate without lubrication?

Many spring steel bushing variants are designed for self-lubricating operation through the use of specialized surface layers or impregnated lubricants. These designs can operate effectively without external lubrication under certain conditions, though performance limits regarding speed and load may apply. Always consult the manufacturer’s specifications for dry-running capabilities of specific bushing types .

4. What temperature ranges can spring steel bushings withstand?

The operational temperature range for spring steel bushings typically spans from -200°C to +280°C, depending on the specific materials and treatments used. Special formulations can extend this range for extreme environment applications. The wide temperature capability makes these bushings suitable for everything from cryogenic equipment to high-temperature industrial processes .

5. How does the installation of spring steel bushings differ from solid bushings?

Spring steel bushings are designed for straightforward installation, typically being pressed into the housing using standard arbor presses or similar equipment. The inherent elasticity of the material allows for a secure interference fit while minimizing the risk of damage during installation. Proper support during pressing is recommended to maintain alignment and prevent deformation .

6. What maintenance do spring steel bushings require?

Maintenance requirements vary depending on the specific bushing type and application. While many spring steel bushings are designed for maintenance-free operation, some applications may benefit from periodic inspection and lubrication to extend service life. Regular visual inspection for wear and proper functioning is recommended as part of a comprehensive equipment maintenance program.

7. Can spring steel bushings be used in corrosive environments?

Yes, specific variants of spring steel bushings, particularly those manufactured from stainless steel or featuring protective coatings, offer excellent corrosion resistance for challenging environments. Applications in marine equipment, chemical processing, and food manufacturing often utilize these corrosion-resistant versions to ensure long service life despite exposure to moisture or chemicals .

8. What are the key considerations when selecting a spring steel bushing for a high-load application?

For high-load applications, critical considerations include the static and dynamic load ratings of the bushing, the PV value limitations (pressure × velocity), the hardness and strength of both the bushing and the shaft, and the type of movement (continuous rotation, oscillation, or occasional movement). Consulting with technical experts during the selection process is recommended for demanding applications.

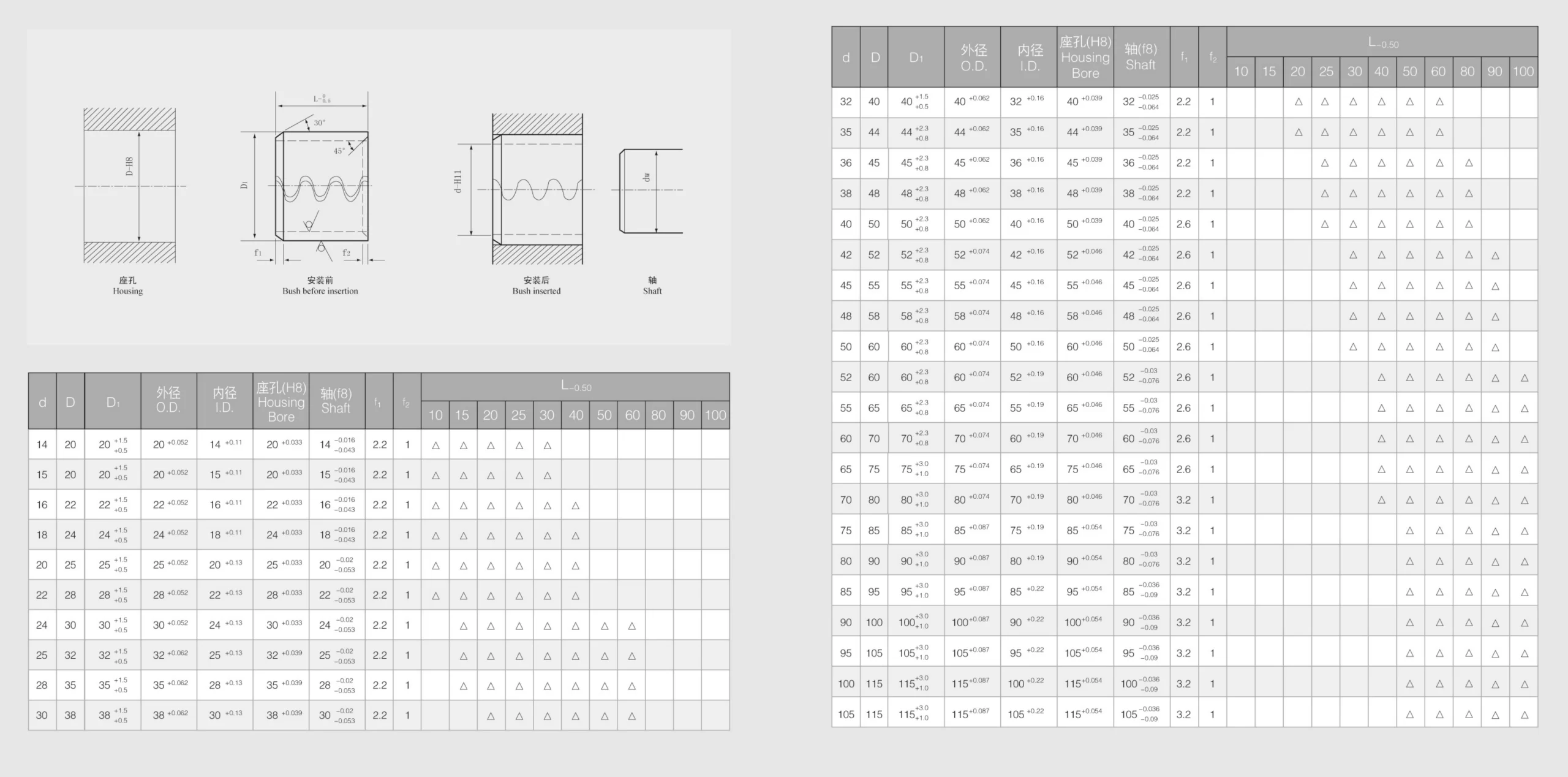

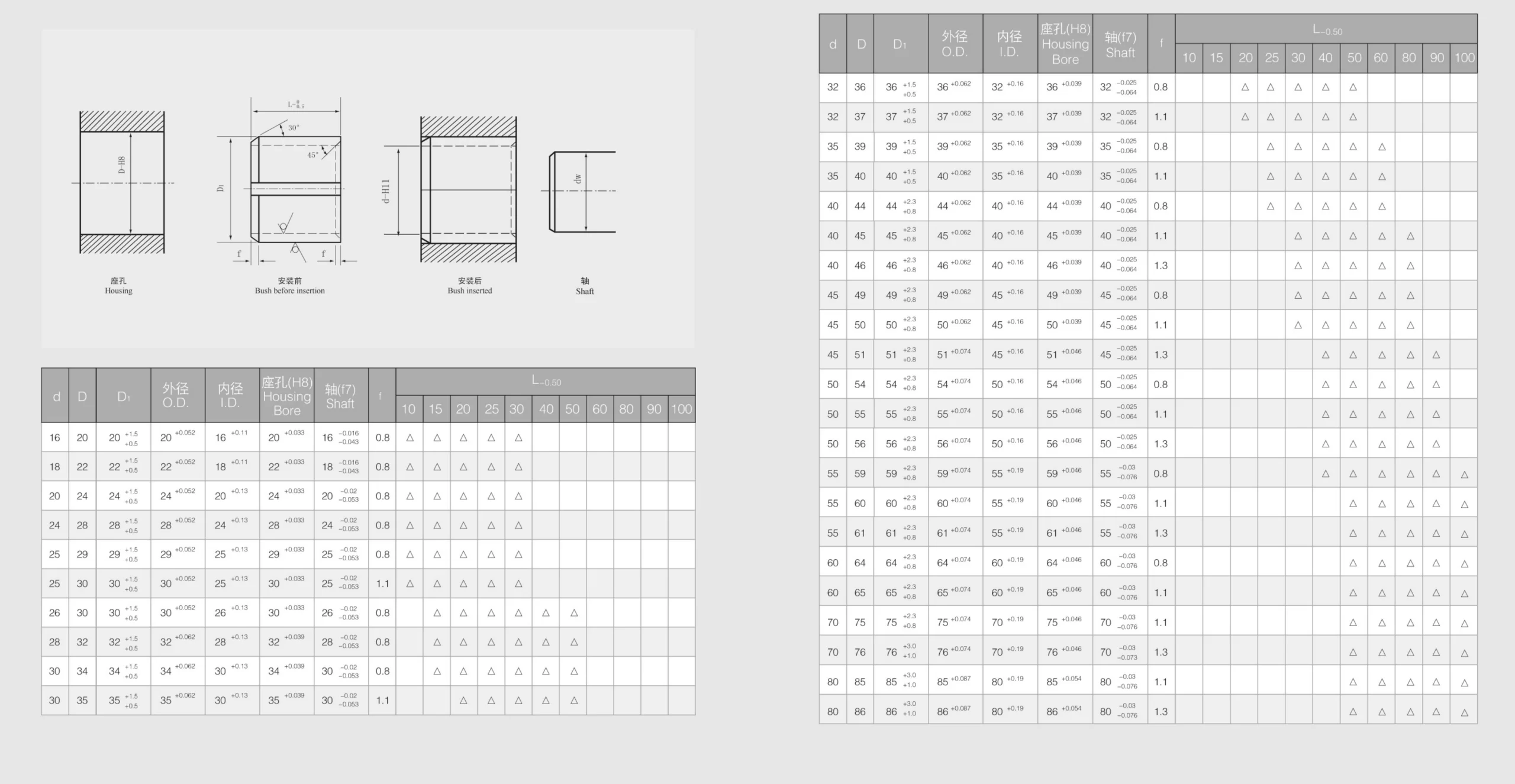

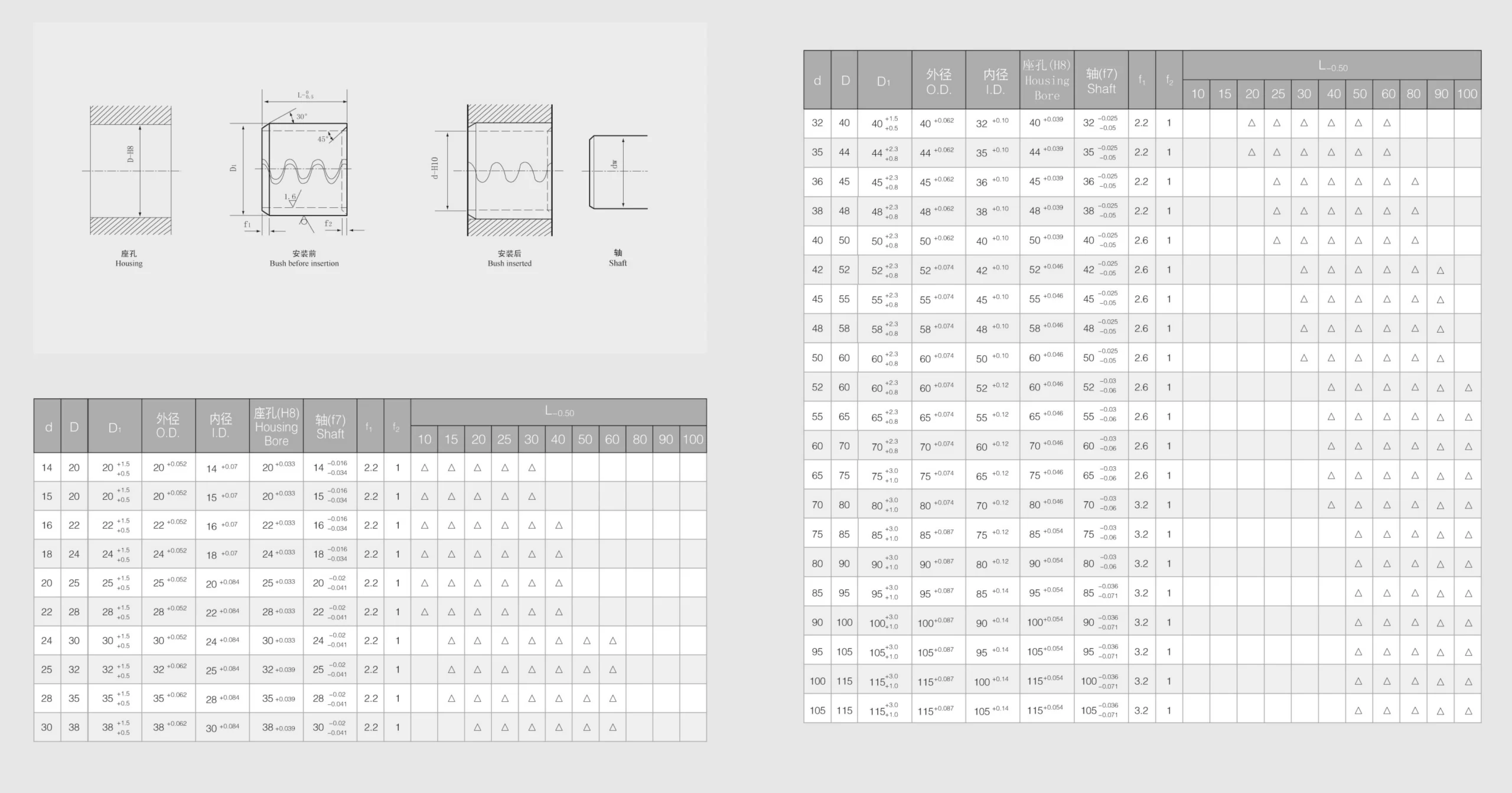

9. How do I determine the correct tolerances for shaft and housing when using spring steel bushings?

Standard recommendations for spring steel bushings typically specify H7 tolerance for the housing and f7 or h8 tolerance for the shaft . However, specific applications may require different tolerances based on operating conditions and performance requirements. Consulting the manufacturer’s specifications for the particular bushing type is essential for optimal performance.