MYWAY: Trusted Steel Bushing Manufacturer with Short Lead Time

High-Quality Sleeves, Flanged & Threaded Bushings for Industrial Applications

- ISO9001 certified & food-grade compliant

- Premium metal alloys with corrosion resistance

- Quick delivery: 7 days or less for standard orders

- 100% inspection ensures tighttolerances (±0.01″)

- Good resistance to fatigue under high temperature

Home » Seamless Steel Bushing

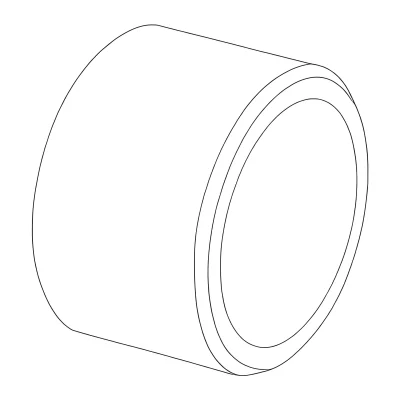

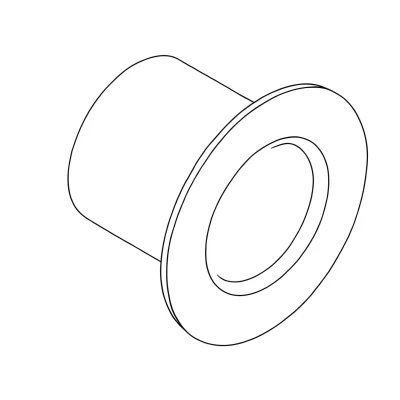

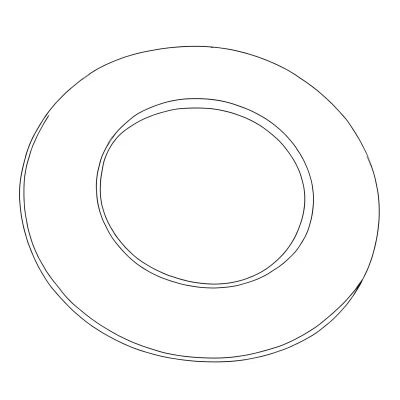

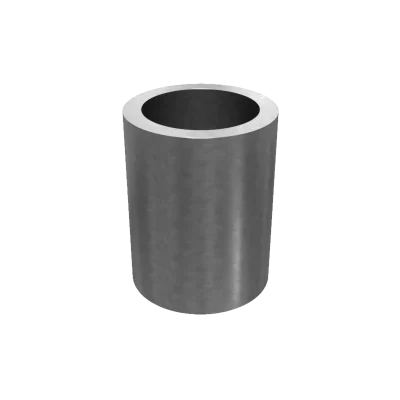

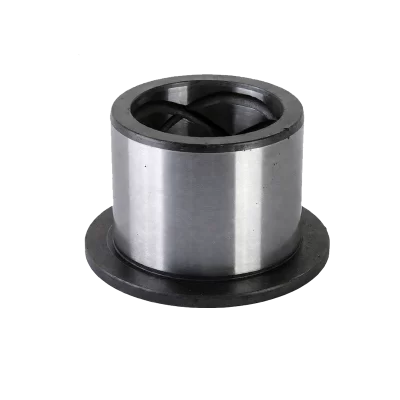

Seamless Steel Bushing

What is Self Lubricating Bushing?

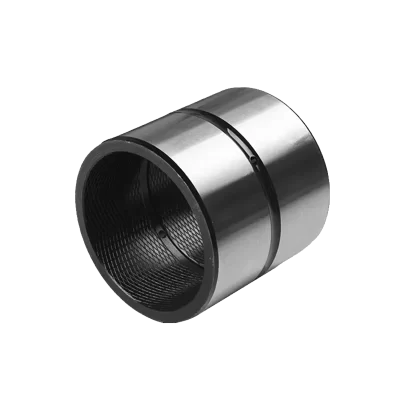

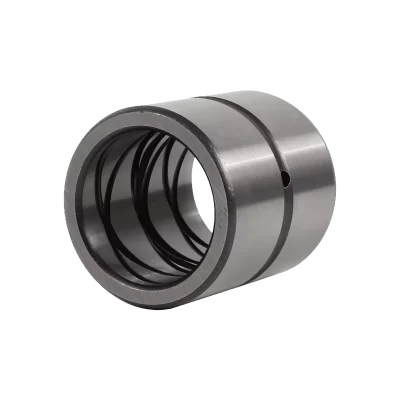

Seamless Steel Bushing Series are machined from low-carbon steel with various grades and hardness levels, featuring precision-engineered oil grooves on the surface. These bushings excel in outstanding impact resistance and high dynamic load capacity, making them ideal for low-speed, high-load applications.

Self-Lubricating Bushings by Structure

Self-Lubricating Bushings by Material

Self-Lubricating Bushings by Feature

Self-Lubricating Bushings by Feature

Self-Lubricating Bushings by Type

Direct Replacements For

| Brand | Series/Models |

|---|---|

| GGB | FP20, SHB |

| ISB | HT-M |

| CSB | CSB-260 |

| GLT | TEF-MET, FER-MAS, FER-MET |

| DE | DE Steel |

| COB | M06 |

Applications of Self Lubricating Bushing

Our Factory

MYWAY’s seamless steel bushings are manufactured using cold-drawing forming technology and precision CNC machining systems that ensure excellent dimensional accuracy and surface quality. Our production line incorporates automated heat treatment equipment for enhanced material properties, along with precision grinding and honing machines that deliver superior surface finish. Rigorous quality control is implemented through coordinate measuring machines and automated inspection systems, ensuring every bushing meets the most stringent industrial requirements for strength and durability.

Bronze Bushings vs. Steel Bushings

- Hardness:Steel bushings are harder than bronze bushings, especially the hardened steel, which can reach up to HRC 55. They are suitable for high-load applications with pressure ≥30MPa, and can also resist high-frequency impacts of mining crushers. Bronze bushings are more suitable for medium-load scenarios.

- Self-lubricating:The self-lubricating property of bronze bushings is superior to that of steel bushings. In addition to natural friction reduction, oil impregnated and graphite embedded bronze bushings are completely maintenance-free. Steel bushings are dependent on external lubrication and either have a self-lubricating coating or need to be lubricated periodically.

When you have a limited budget, need high-hardness and high-precision parts for a short period of time, steel bushings are your wise choice! If you are looking for self-lubricating, corrosion-resistant and long-term maintenance-free performance, bronze bushings will perfectly match your needs. Of course, you can also contact us to customize a mixed solution to balance cost and performance.

Why Choose Myway Steel Bushings

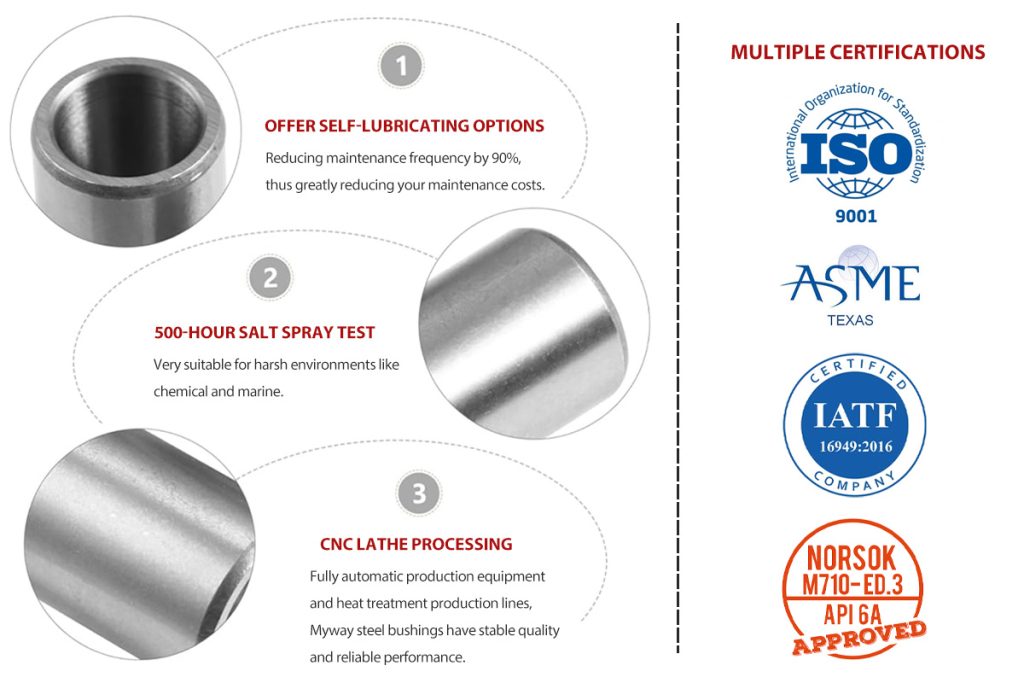

Myway steel bushings offer self-lubricating options, reducing maintenance frequency by 90%, thus greatly reducing your maintenance costs. Our stainless steel bushings has passed the 500-hour salt spray test, very suitable for harsh environments like chemical and marine.

With CNC lathe processing, fully automatic production equipment and heat treatment production lines, Myway steel bushings have stable quality and reliable performance. You can fully trust us, and our products have passed ISO9001, ASME, IATF 16949, API 6A and other international certifications.

Myway is a factory integrating design, production and testing, with multiple production lines and experienced technicians. We can guarantee delivery within 7 days and support global logistics. Choosing Myway means that you can buy high-quality bushings at an favorable price with short lead time.

The Engineering Marvel You've Been Overlooking: An In-Depth Look at Seamless Steel Bushings

In the world of industrial machinery and heavy equipment, there exists a humble yet vital component that often goes unnoticed – the seamless steel bushing. While commonly referred to as “bushings” or “sleeve bearings,” these unassuming parts play a crucial role in ensuring smooth operation and longevity of machinery across countless industries.

Understanding Seamless Steel Bushings: More Than Just a Simple Sleeve

Unlike their welded or seamed counterparts, seamless steel bushings are manufactured from a single piece of material without any joints or seams. This manufacturing method creates a uniform structure that offers superior strength and reliability. The seamless construction eliminates potential failure points, making these components exceptionally durable under heavy loads and stressful operating conditions.

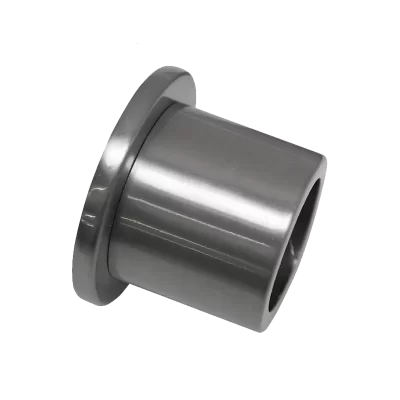

Key Manufacturing Processes and Types

The production of seamless steel bushings involves specialized techniques that contribute to their exceptional performance characteristics:

Weldless Steel Bushing: Created through cold drawing or extrusion processes

Forged Seamless Bushing: Manufactured using hot forging methods for enhanced grain structure

Solid Bore Seamless Bushing: Machined from solid steel bars for maximum precision

Carbon Steel Seamless Bushing: Often made from high-carbon steel with heat treatment capabilities

These manufacturing methods result in various specialized forms, including Seamless Steel Sleeve, Tubular Bushing, and Seamless Shaft Sleeve components, each designed for specific applications and performance requirements.

Technical Advantages That Matter

The seamless design provides several critical benefits that make these bushings preferred in demanding applications:

Enhanced Load Distribution: The continuous material structure allows for even stress distribution

Superior Impact Resistance: No seams mean no weak points under shock loads

Better dimensional stability: Maintains precise tolerances under thermal and mechanical stress

Extended service life: Typically outlasts seamed alternatives in harsh conditions

Technical Advantages That Matter

The seamless design provides several critical benefits that make these bushings preferred in demanding applications:

Enhanced Load Distribution: The continuous material structure allows for even stress distribution

Superior Impact Resistance: No seams mean no weak points under shock loads

Better dimensional stability: Maintains precise tolerances under thermal and mechanical stress

Extended service life: Typically outlasts seamed alternatives in harsh conditions

MYWAY: Your Trusted Partner for Premium Seamless Bushings

At MYWAY, we’ve mastered the art and science of manufacturing high-performance seamless steel bushings. Our commitment to excellence ensures that every bushing we produce meets the highest standards of quality and reliability.

Why Choose MYWAY Seamless Bushings?

Manufactured from premium materials including hardened and stainless steel

Available in metric (16-300mm) and imperial (0.63″-11.81″) sizes

Precision machining with tight tolerance control

Custom designs and special patterns available

Comprehensive technical support and engineering expertise

Our seamless bushings are engineered to withstand the most demanding conditions, providing exceptional wear resistance and longevity that reduces downtime and maintenance costs.

Ready to experience the MYWAY difference? Contact our engineering team today to discuss your bushing requirements and discover how our seamless solutions can enhance your equipment’s performance and reliability.

MYWAY Seamless Steel Bushing FAQs

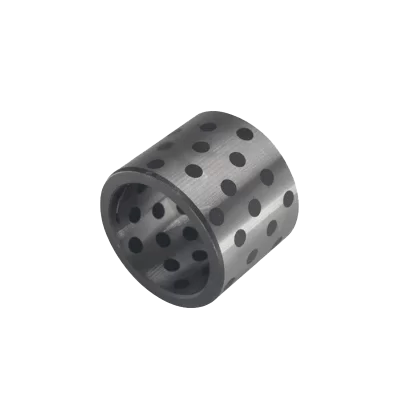

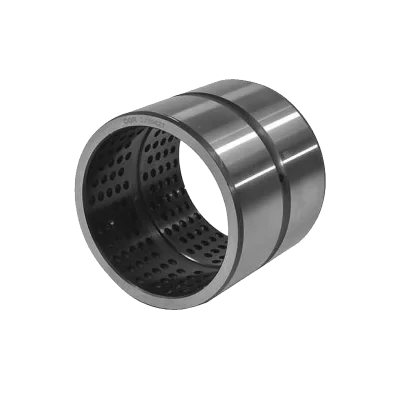

1. What Are the Key Features of Honeycomb Bushings?

The product is a seamless bushing with uniformly distributed conical blind holes on its inner wall.

A natural lubricating oil wedge is formed during the grinding process of the inner hole, ensuring rapid oil film formation during startup.

The honeycomb structure provides 3-5 times more oil storage capacity than conventional grease grooves, enabling long-term maintenance-free operation.

The uniform honeycomb pattern with fixed circumferential spacing ensures full oil coverage across the inner surface with minimal rotation, eliminating lubrication dead zones.

The honeycomb skeleton significantly enhances load-bearing capacity and extends the bushing’s service life.

2. What makes seamless bushings superior to seamed alternatives?

The absence of welds or seams creates a uniform structure with no weak points, resulting in better load distribution, higher impact resistance, and longer service life.

3. Can MYWAY produce custom-sized seamless bushings?

Yes, we specialize in custom designs and can manufacture bushings according to your specific drawings and requirements.

4. What materials are available for MYWAY seamless bushings?

We offer various materials including hardened steel, stainless steel, and carbon steel, selected based on your application requirements.

5. How do I determine the right bushing type for my application?

Our technical team can assist in selecting the optimal bushing type based on your load requirements, operating environment, and performance expectations.

6. What are the lead times for custom seamless bushing orders?

Lead times vary depending on complexity and quantity, but we strive to provide timely solutions without compromising quality.