Home » DX/SF-2 Boundary Lubricating Bushing » DX/SF-2T Tin-plated Steel-Based Boundary Lubricating Bushing (Red POM)

DX/SF-2T Tin-plated Steel-Based Boundary Lubricating Bushing (Red POM)

This product features a high-quality low-carbon steel substrate, a sintered spherical bronze intermediate layer, and a surface layer of specially formulated resin composed of acetal and oleophilic fibers. It offers a low friction coefficient, excellent wear resistance, and self-lubrication even in oil-free conditions.

Ideal for applications where hydrodynamic lubrication is difficult to maintain—such as frequent starts/stops, oscillating motion, or continuous operation under boundary lubrication—it requires minimal maintenance. Occasional relubrication can further extend service life. The surface layer can be machined after installation for a precise fit.

Widely used in construction machinery (hoists, bulldozers), industrial equipment (printing/dyeing machines, coal miners, punches, cranes), automotive chassis, metallurgical, mining, hydraulic, agricultural, and steel rolling machinery. Its lead-free composition makes it suitable for environmentally sensitive applications.

Technical Parameters

| Parameter | Value/Condition |

|---|---|

| Static Load Capacity | 250 N/mm² |

| Max. Load Capacity – Very Low Speed – Rotating/Oscillating Motion | 140 N/mm² 70 N/mm² |

| Max. PV Value (Dry Running) | 3 N/mm²·m/s |

| Temperature Limit | –40 °C to +110 °C |

| Coefficient of Friction (Grease Lubrication) | 0.05–0.20 |

| Max. Sliding Speed – Grease Lubrication – Continuous Oil Supply | 2 m/s >2 m/s |

| Thermal Conductivity | 50 W/(m·K) |

| Coefficient of Thermal Expansion | 11 × 10⁻⁶ /K |

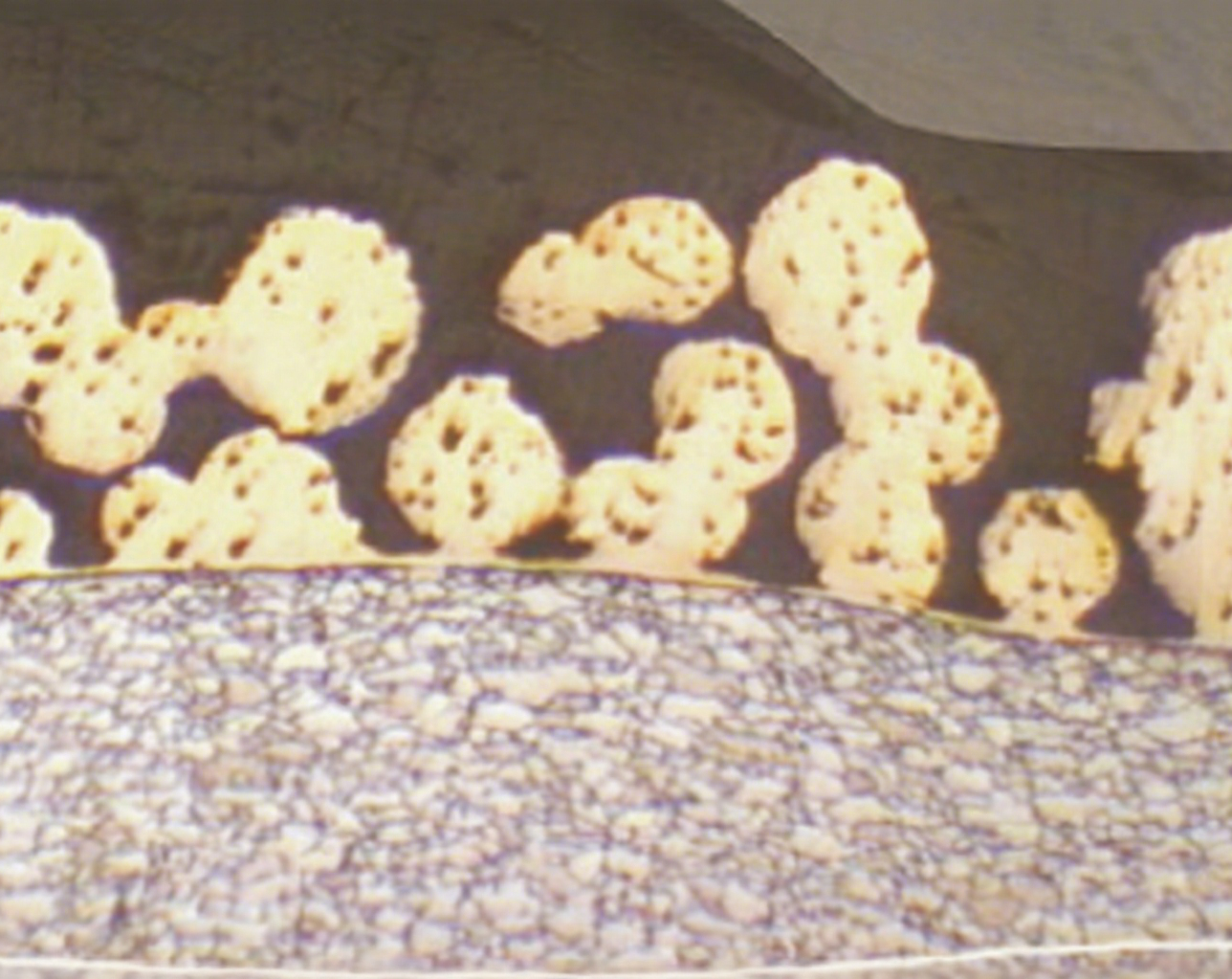

Metallographic Analysis

Mixture of POM and fibers: 0.3–0.5 mm

Spherical bronze powder: 0.2–0.3 mm

Steel backing: 0.4–2.2 mm

Electroplated layer:

Tin plating: 0.005 mm

Copper plating: 0.008 mm