Home » Our Factory

MYWAY Bushing: The Complete Manufacturing Journey of a Bushing Leader

In the highly competitive landscape of industrial components, MYWAY has established itself as a premier manufacturer through its fully integrated, vertically-controlled production ecosystem. Our comprehensive manufacturing philosophy ensures complete quality control from raw materials to finished products, making us one of China’s few truly end-to-end solutions for self-lubricating bushings and composite bearings. With nearly two decades of expertise in global trade and manufacturing excellence, MYWAY represents the pinnacle of engineering precision and reliability in the bushing industry.

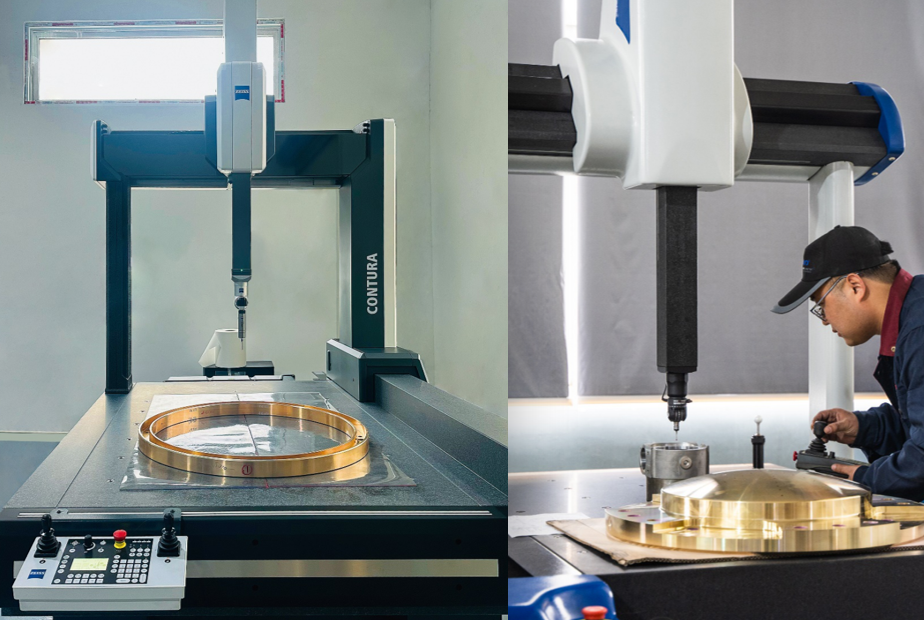

Advanced Quality Inspection: Our Uncompromising Standard

Quality inspection represents the cornerstone of our manufacturing philosophy and market reputation. At MYWAY‘s state-of-the-art testing laboratory, we maintain comprehensive quality control measures that exceed industry standards. Our extensively equipped laboratory features advanced testing capabilities including HB hardness testers, precision tensile testing machines, sophisticated metallographic analyzers, and UT testing equipment. The integration of high-precision coordinate measuring machines enables meticulous dimensional verification, while our sophisticated spectrometers, swing testing machines, and pneumatic measuring instruments ensure every product meets stringent international quality standards.

Our commitment to quality extends to advanced inspection methodologies, including three-coordinate measurement that enables precise spatial point coordinate acquisition—the fundamental basis for evaluating geometric shapes. This technology allows for dimensional accuracy measurement, positional accuracy measurement, geometric accuracy measurement, and contour accuracy measurement, ensuring perfect specifications in every bushing we produce.

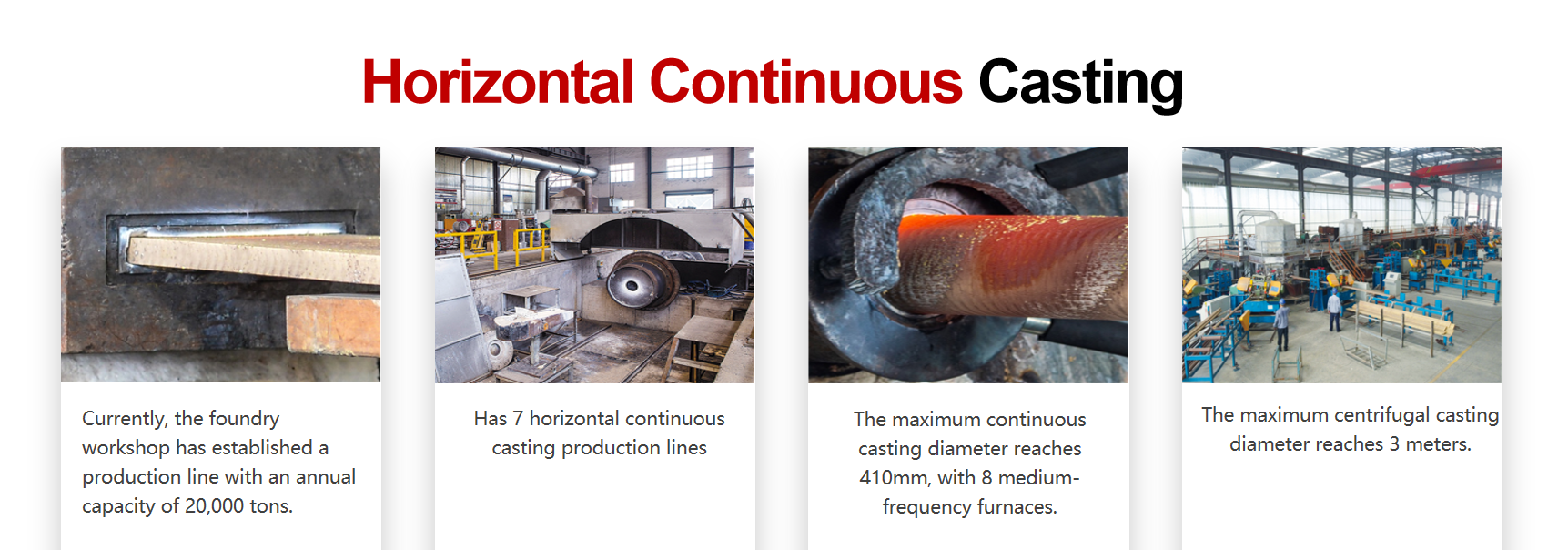

Comprehensive Foundry Operations: Where Quality Begins

Our manufacturing excellence starts with state-of-the-art casting capabilities that set industry standards. The foundry operations at MYWAY represent a perfect blend of scale and precision, featuring seven horizontal continuous casting production lines and eight medium-frequency furnaces that collectively maintain an impressive annual capacity of 20,000 tons. Our specialized centrifugal casting division operates nine centrifuges and two AC centrifugal furnaces, handling massive components up to 3,000 mm in diameter. The continuous casting process achieves precise diameters up to 410 mm, while our comprehensive mold library—featuring over 200 specialized centrifugal casting molds—ensures we can meet virtually any custom requirement.

The centrifugal casting capabilities at MYWAY deserve special mention, with maximum centrifugal casting diameter reaching 3 meters, making us one of the few companies capable of handling such large-scale components. Our horizontal continuous casting production lines ensure consistent material quality and mechanical properties from the very inception of the manufacturing process, establishing a robust foundation for all subsequent manufacturing stages.

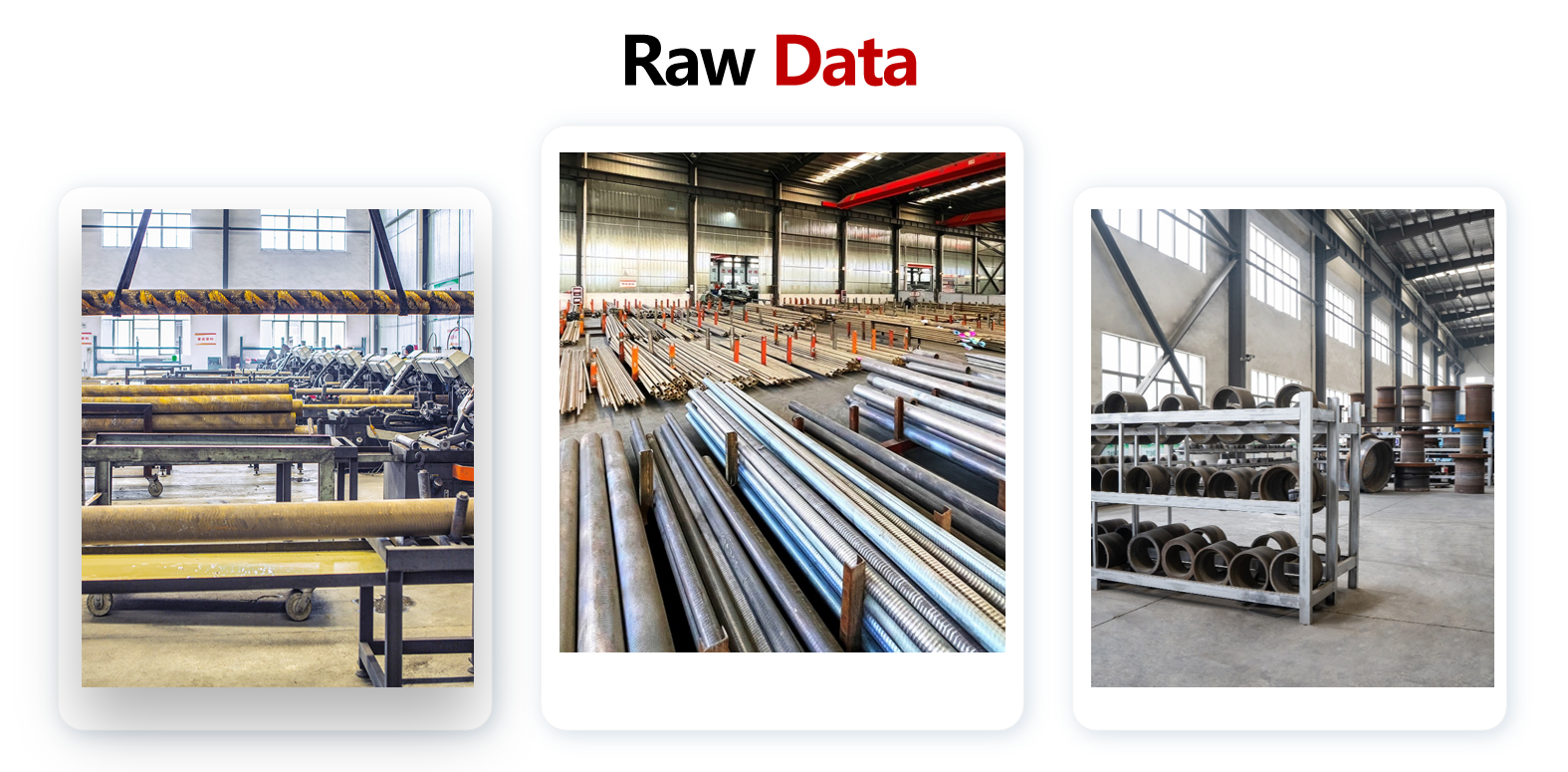

Material Resources and Raw Material Management

Supporting our massive production capabilities is an extensive raw material infrastructure that ensures uninterrupted manufacturing operations. We maintain more than 500 tons of various semi-finished pipe materials and over 200 sets of various centrifugal casting molds in our inventory. This substantial material reserve allows MYWAY to respond quickly to customer demands while maintaining consistent quality across all production batches.

The semi-finished products processing workshop, developed over more than ten years of continuous operation and refinement, has evolved into a crucial pillar supporting both our internal production needs and external customer requirements in the global self-lubricating bearing market. Operating from our Jiashan headquarters, this facility radiates support to customers nationwide and internationally, providing essential rough processing services and technical expertise that forms the backbone of our manufacturing reliability.

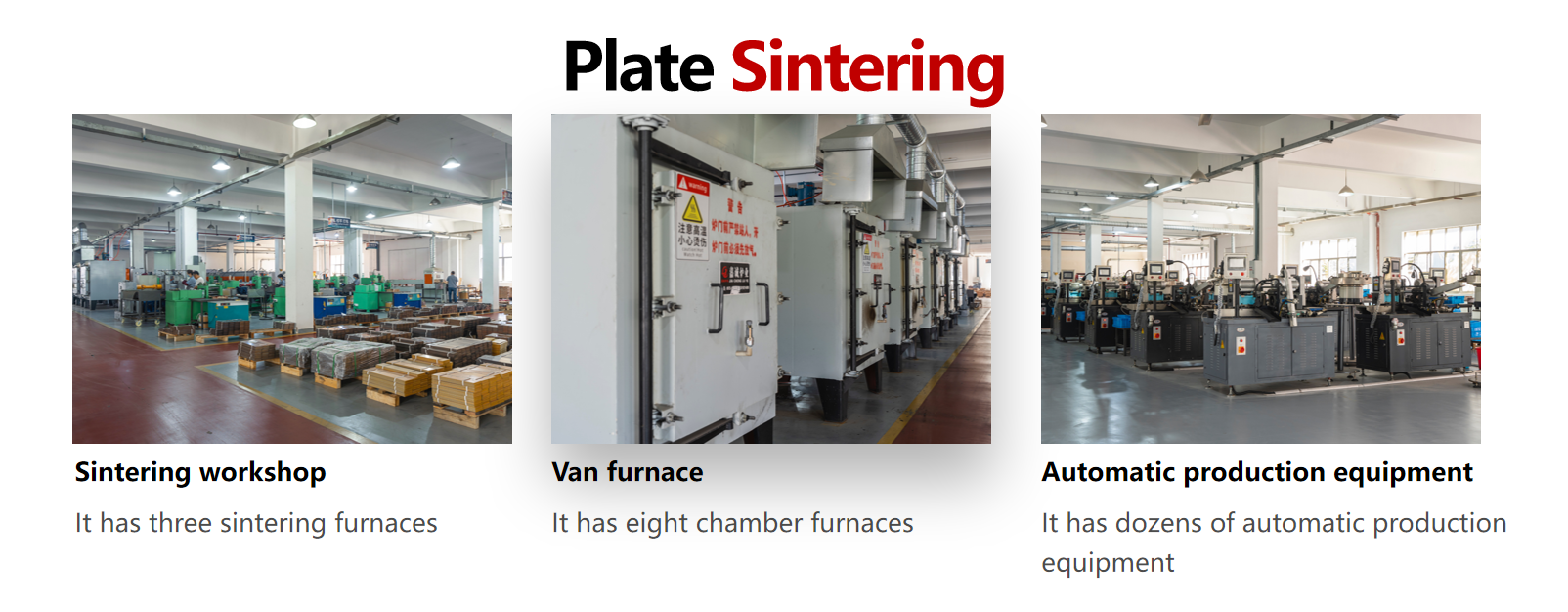

Sophisticated Sintering Technology: Precision Engineering

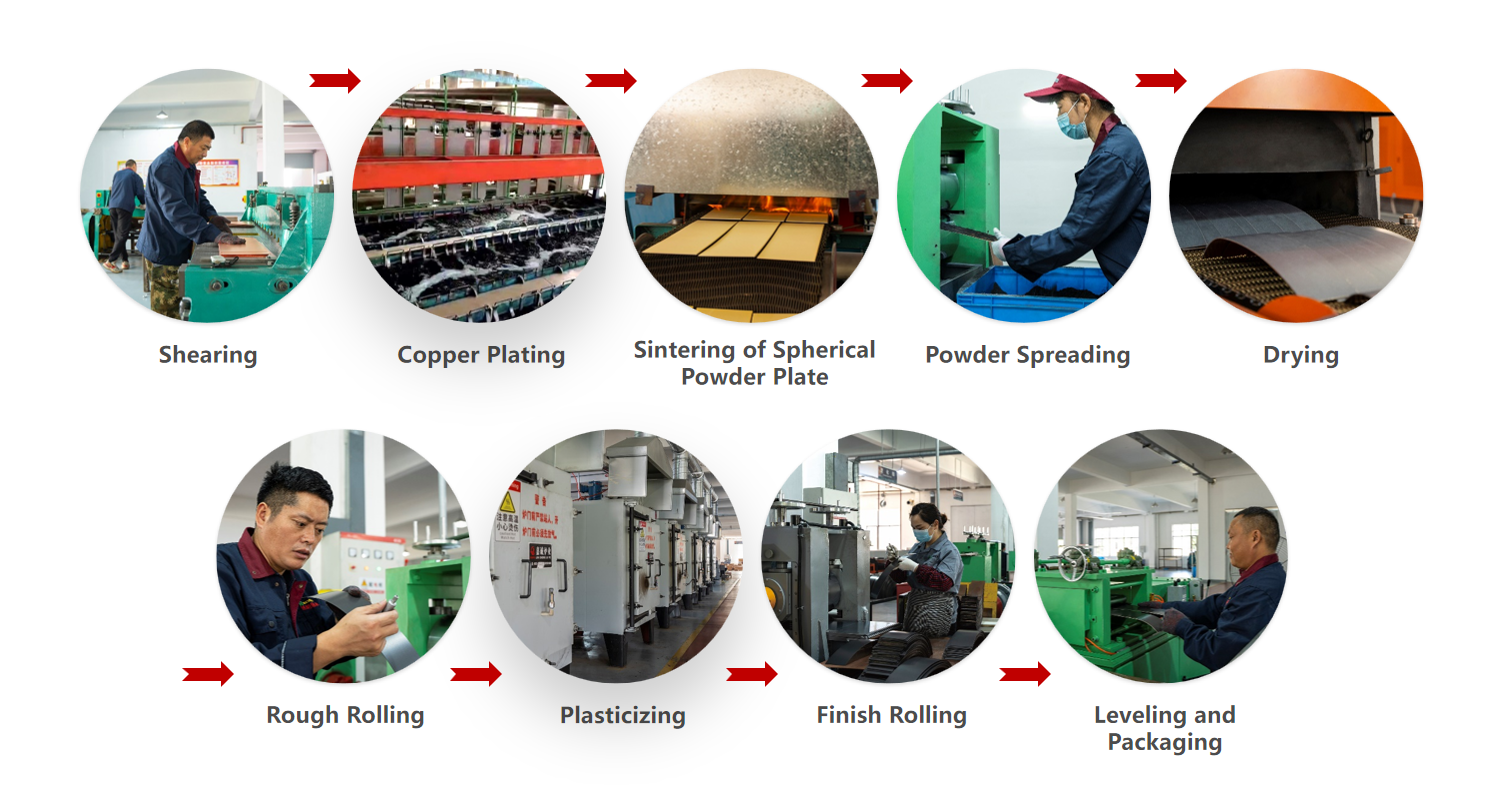

Our advanced sintering department represents another critical link in our integrated manufacturing chain. Featuring three specialized sintering furnaces and eight precisely controlled chamber furnaces, supported by dozens of automated production units, this department handles the complex process of composite sheet sintering with exceptional precision. The composite sheet sintering process involves multiple meticulously managed stages that ensure optimal material performance, including precision shearing and uniform copper plating, controlled spherical powder spreading and high-temperature sintering, systematic drying and carefully monitored plasticizing, multi-stage rough and finish rolling processes, and precision leveling with protective packaging.

This comprehensive approach guarantees uniform material distribution, consistent density, and optimal performance characteristics across all our composite materials. With multiple product sintering lines and over a hundred automated finished product machines, complemented by complete molds and advanced inspection equipment, our sintering products demonstrate strong market competitiveness that continues to drive industry standards forward.

Composite Bushing Manufacturing: Automation Excellence

The composite bushing production line at MYWAY showcases our commitment to automation and precision manufacturing. Our integrated manufacturing process follows a meticulous workflow that begins with sheet sorting and progresses through automatic rolling, punch blanking, and precision chamfering operations. The process continues with comprehensive cleaning, drying, and protective oiling stages, concluding with systematic sorting, secure packaging, and efficient shipping procedures.

This automated workflow ensures consistent quality, dimensional accuracy, and reliable performance in every bushing we produce. The efficiency of our composite bushing manufacturing process, combined with our rigorous quality control measures, enables MYWAY to deliver products that consistently exceed customer expectations in terms of both performance and durability.

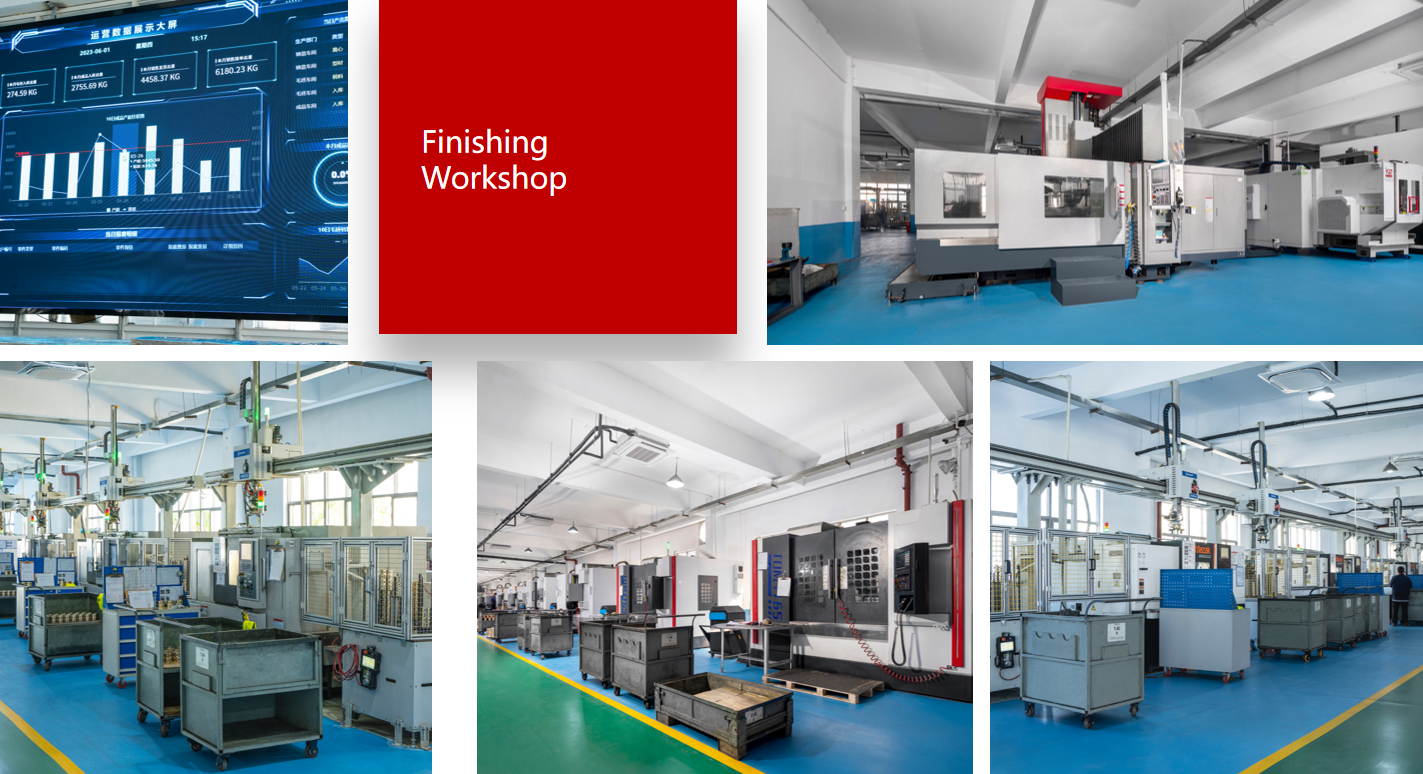

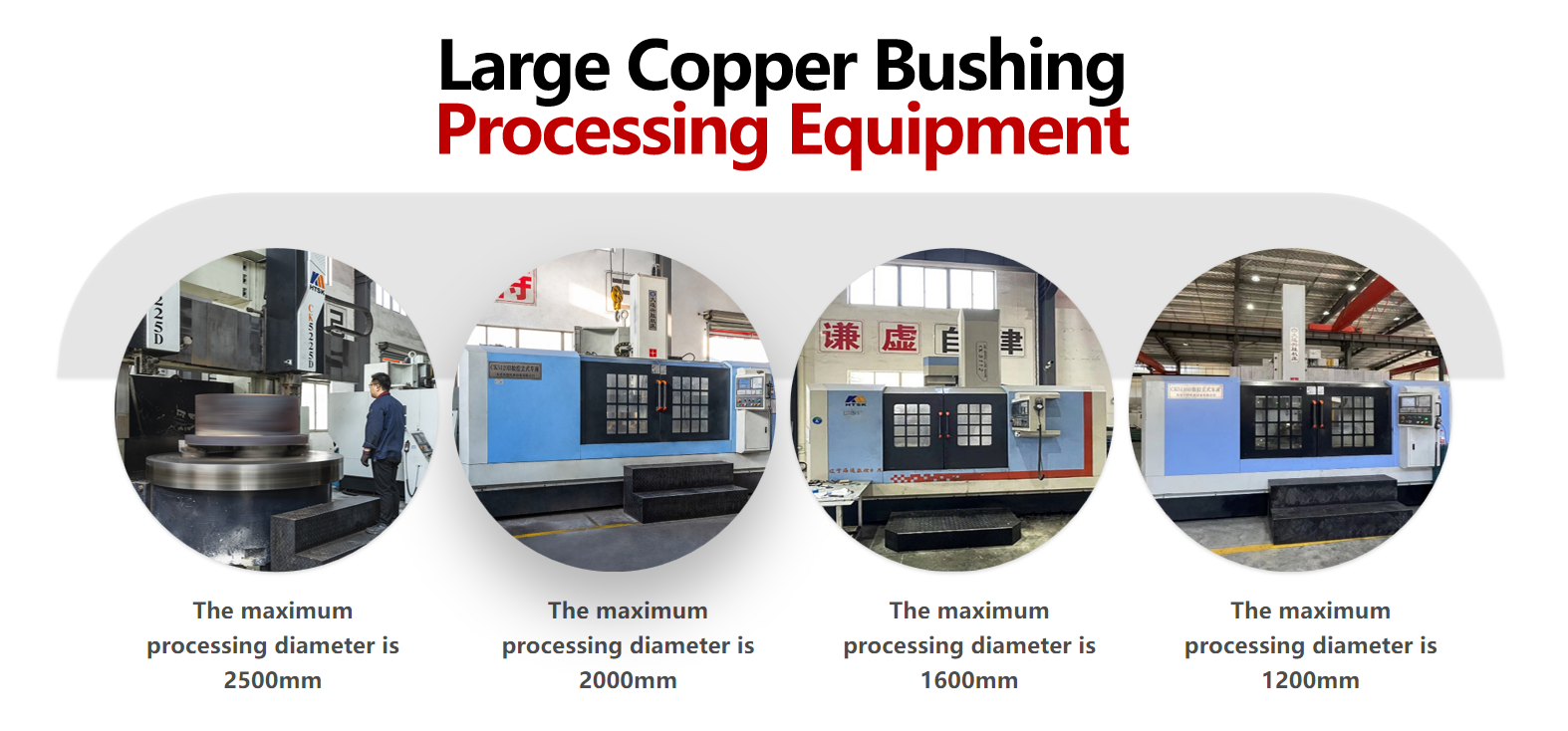

Precision Machining: The Final Touch of Excellence

Since its establishment in 2013, our precision machining workshop has become the driving force behind our continuous growth and innovation. Equipped with advanced machining centers capable of handling massive components, we expertly process copper bushings ranging from 1,200 mm to 2,500 mm in diameter. This impressive size range demonstrates our capability to serve diverse industrial applications, from compact machinery to massive industrial equipment.

Our expanding capabilities now include sophisticated copper plates, precision turbines, and advanced composite bearings for high-end applications across multiple industries. The precision machining workshop leverages strong process research and development capabilities, efficient flexible manufacturing capacities, and exceptional customer collaboration to drive the company’s growth. By 2023, our product types had expanded to include copper bushings, copper plates, turbines, and composite bearings, among other high-end application products, demonstrating our commitment to continuous innovation and market adaptation.

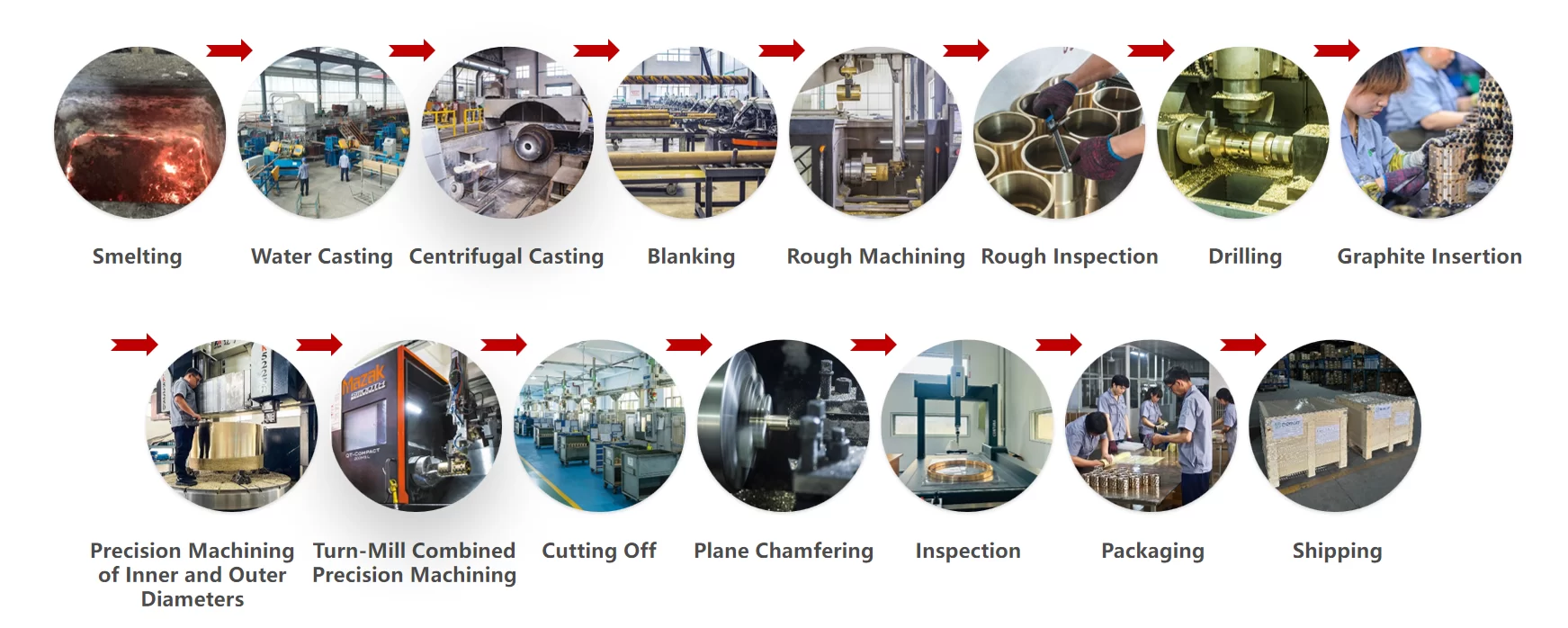

Self-lubricating Bearing Process Flow

Composite Panel Process Flow

Composite Bushing Process Flow

Complete Product Inspection and Quality Assurance

Before any product leaves our facility, it undergoes a comprehensive inspection process that represents the final checkpoint in our quality assurance system. At MYWAY, we understand that comprehensive quality control measures, testing equipment, and testing methods are indispensable safeguards in the quality control process. Therefore, the company has established a complete set of quality management systems for the finishing of products and is equipped with a full range of testing equipment.

Our finished product inspection protocol includes coordinate measuring machines for dimensional verification, spectrometers for material composition analysis, tensile testing machines for mechanical property validation, swing testing machines for performance under dynamic loads, hardness testers for material hardness verification, metallographic analyzers for microstructural examination, and pneumatic measuring instruments for precise dimensional checks. This multi-layered inspection approach ensures that every MYWAY bushing delivers consistent performance and reliability in the field.

Smart Logistics and Digital Warehousing: Efficient Delivery Systems

Our modern 5,000-square-meter digital finished goods warehouse represents the final link in our integrated manufacturing chain. With an impressive storage capacity of 500-600 tons, this facility maintains comprehensive stock of standard inventory items while supporting our made-to-order business model. The advanced digital warehouse system provides real-time inventory visibility to our customers and enables faster response times for urgent orders, significantly enhancing customer experience through reliable delivery performance.

The digital finished goods warehouse is fully stocked with various standard parts, meeting the needs of general OEMs and dealers for immediate shipment of in-stock items. The digital warehouse system features a special module for key clients, allowing them to directly check the inventory quantity and processing status of ordered products. This innovative approach provides faster response times for urgent orders from OEMs, demonstrating our commitment to customer-centric service excellence.

Every product undergoes rigorous final inspection and systematic packaging before being strategically placed in optimized storage locations. Outbound goods also go through a rigorous inspection before shipment, ensuring that our quality standards are maintained throughout the entire supply chain.

Technical Superiority Through Vertical Integration

MYWAY‘s manufacturing strength derives from our completely vertically integrated production approach. By maintaining complete control over every production stage—from initial raw material processing through final inspection and delivery—we guarantee consistent quality throughout the entire supply chain, significantly reduced production lead times, flexible customization capabilities for specialized applications, and competitive pricing through optimized process efficiency.

This vertical integration makes MYWAY one of the few companies in China capable of providing one-stop services from raw materials to finished products. Our ability to control every aspect of the manufacturing process ensures that we can respond quickly to market changes and customer requirements while maintaining the highest quality standards in the industry.

Conclusion: Engineering Your Success with MYWAY

Our unwavering commitment to technological advancement and quality excellence positions MYWAY as a trusted global partner for industries worldwide. Whether serving automotive, construction, agricultural, or specialized industrial applications, we deliver exceptional reliability engineered through decades of manufacturing expertise and continuous innovation. Our integrated manufacturing ecosystem ensures that every MYWAY bushing embodies the perfect balance of precision engineering, durable performance, and unmatched value.

From our advanced foundry operations and sophisticated sintering technology to our precision machining capabilities and comprehensive quality assurance systems, every aspect of our manufacturing process is designed to deliver superior products that help our customers succeed in their respective markets. The MYWAY advantage extends beyond the products themselves to include technical support, custom engineering solutions, and reliable delivery that keeps our customers’ operations running smoothly.

Discover how MYWAY‘s comprehensive manufacturing capabilities can enhance your applications with durable, high-performance bushing solutions specifically engineered for demanding operational environments. Partner with us for reliability that begins at the molecular level and delivers performance you can count on. At MYWAY, we don’t just manufacture bushings—we engineer success stories through superior manufacturing excellence and unwavering commitment to quality.

MYWAY Bushings by Structure

Are you still Looking for a Reliable Bushing Supplier?

Choose MYWAY, You will Enjoy One-stop Bushing Design and Production Services!

Ask For Quote Now!

We Will Contact You Shortly