MYWAY: The Complete Directory of Crane Bushing Manufacturers in China

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Construction Equipment Bushing » Crane Bushings

MYWAY Crane Bushings

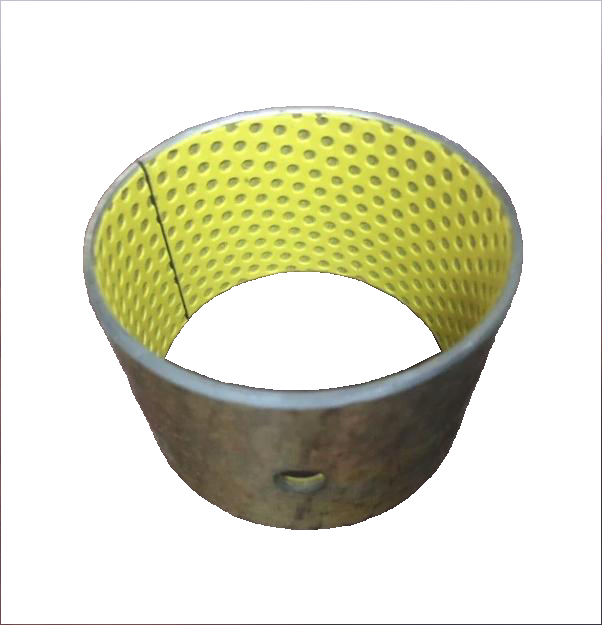

C45 Hardened Steel Bushing Excavator Boom Bushings For Loader Crane

Description: Hardened Steel Bushing Material: C45 Steel Lubricating: Oil Grease Application: Excavator,Loader,bucket Pin Highlight: C45 Hardened Steel Bushing, Bushing Excavator 56HRC, 56HRC Excavator Boom Bushings Max Dynamic Load(Mpa) 150 Max Temperature -100-300°C Max Sliding Speed(m/s) 0.17 Max PV Value(m/s*Mpa 1.2 Hardness 56-62 HRC

CNC Machining Metal Bushing Crane Agricultural Use JCB Casting Brass Bush

Model NO. TCB800 Type Bushing Product name Brass bushings Processing methods CNC processing Oil grooves Cross, spiral, ring, etc Sizes Customized sizes MOQ 100PCS Production Capacity 100000.0 Piece/Pieces Per Month

Crane Bronze Bushing Lubrication Pockets CuSn8 Material Inside Diameter 80mm OD85mm

Certification: Bushing Standard Met:MBZ, B09 or MBZ B09 Meterial: Wrapped Bronze Bushings Phosphor Tin Bronze CuSn8 Or CuSn6 Bushing: Bronze Lubrication Diamond Feature: BRO-MET, FB090, BRM10, WB800 Lubrication: Self Lubricating Bearing Application: Crane Bushing,Crane Bronze Bushing Lubricating Bearing Type: BK-090, BRM10, COB-090, MBZ-B09, PRM, PRMF, SERIE SBA, SERIE SBB, WB700, WF-WB 700

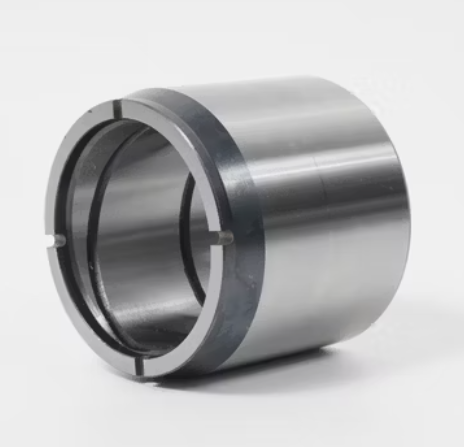

Spring Steel Tension Bush Harden Split Steel Bushing For Crane Lifiting Machinery Grab Machinery Joint Position Parts

Model NO. TCB603 Type Bushing Product name Spring steel bushing Processing CNC Machining Standard DIN1498 Color Natural color, black MOQ 100PCS Application Cranes, lifting machines, etc Transport Package Anti-Rust Paper, Carton, Wood Case or Pallet

Auto Crane 412044 BUSHING-CLUT HSG,PWD BRZ,200DOW-LOK

Auto Crane 412044 BUSHING-CLUT HSG,PWD BRZ,200DOW-LOK

Crane Bushing PM7050DX

Crane Bushing - 23337

Crane column upper bushing 3477771X

Product description Upper crane column bushing Hiab 070, Hiab 071, Hiab 080, Hiab 090 Pos. 10 on the diagram Hiab 090AW 235.240.50mm

Master Bushing 6075.036 for Konecranes Reach Stacker Crane

Product Details Master Bushing 6075.036 for Konecranes Reach Stacker Crane Replace Part Number: 6075.036, 6075036

CRANE IN/B-PC01 BUSHING RP61B4120-001 INBPC01

CRANE IN/B-PC01 BUSHING RP61B4120-001 INBPC01 B2/49 BB Additional information Weight 5.00 lbs

Ba0021087 Bridge Crane Bushing at 5000/piece

Premium High Load Capacity Bronze Bushing for Cranes

Lubricant & Load Hydrodynamic Bearing Bushing Material Bronze Material Cuzn25al5mn4fe3+Solid Lubricant Hardness Hb 210-250 Max. Dynamic Load N/mm² 98 Max.Speed M/S Dry Lubrication 0.3; Oil Lubrication 1.0 Max.PV N/mm²*M/S Dry Lubrication 1.65; Oil Lubrication 3.25 Friction Dry Lubrication 0.12~0.16; Oil Lubrication 0.03~0. Specification 100*120*100

Undergound Mining Bronze Bushing Jumbo/Drill/LHD/Scooptram/Mining Truck/DTH Drill/Spraying/Crane/Bollt/Excavator/Loader/Bulldozer Bushing Mining Machinery Part

Certification ISO 9001:2008 Material Copper and Copper Alloys

CNC Machining Casting Bronze Bushing Made of CuZn25Al5Mn4Fe3 Copper Alloy of Low Weight for Crane Machine

Product name Brass bushings Processing methods CNC processing Oil grooves Cross, spiral, ring, etc

Wrapped Bronze Bushing for Cranes Mining Agricultural Machinery Parts

Type Bushing Material CuSn8P Sample Available Processing Cold Extrusion Other Type Sleeve/Washer/Flanged Quality Guaranteed Features Good anti-fatigue, anti-erosion and load capacity Lubrication Self lubricating, oilless Transport Package Anti-Rust Paper, Carton, Wood Case or Pallet

High Load Capacity Durable Steel Backed Crane Bearing Bushing

Model NO. Spiral oil channel steel bushing Product Name Bushing Sleeve Bush Types Flange Features Wear Resistance Lubricating Carbon Standard DIN1494 Surface Treatment Phosphating Black Product Shape Customized Bushing Material Steel

Blackening Surface Treatment 50CrV4 High Carbon Strength Steel 42-48 HR Split Tension Steel Crane Machine Spring Bushing

Processing methods CNC processing

Steel Sleeve Bushing Bearing Blackening Treatment for Excavator Crane

Type Bushing Material GCr15, 40Cr, C45,42CrMo Name Steel bushing Size Customized size Types Sleeve Color Natural color OEM Accept Application Excavators,Cranes,Construction Machine ,etc. Processing CNC processing Operating Temperature -100~+250 Transport Package Anti-Rust Paper, Carton, Wood Case or Pallet

Customize The Bronze Bushing of Bearing for The Split-Type Crane

Type Bushing Material Cusn8p, Customized Material Capabilities Aluminum, Brass, Bronze, Copper, Precious Metals, Micro Machining or Not Micro Machining Surface Treatment Copper/Zinc/Tin Plating Stock Qty Rich /Great Supplying Ability Features Diamond Oil Socket to Preserve Oil Grease

Manufacturer High Precision 65mn Tension Steel Bushing DIN1498 Standard Crane and Lifting Machine Steel Spring Steel Bushing

Model NO. SWA012 DIN1498 Surface Treatment Bright Color, Black Oxide, Zinc Plated, HDG Head Type Round Product Name Spring Steel Bushing Certificate ISO9001 Feature High Strength , Corrosion-Resistance , Rust-Proof Transport Package Cartons+Plastic Bags+Pallet Specification Size: M3 M4 M5 M6 M8 M10 M12 M14-M120

Custom Bronze Bushing CNC Machining Copper Bushing Crane Electromotor Parts

Type Bushing Material CuZn25Al5Mn4Fe3 Sample Available Processing CNC Processing Other Type Flange/ Washer Automation Accept Name Bronze bushing Transport Package Anti-Rust Paper, Carton, Wood Case or Pallet

OEM: IMT

| Part Number | QTY | Application Site | Crane Model |

|---|---|---|---|

| 7BF81215 | 4 | LOWER BOOM ASSEMBLY | 3016/3816/2015GH |

| 7BF81015 | 4 | LOWER BOOM CYLINDER | 3016/3816/2015GH |

| 72063034 | – | EXT BOOM ASM | 3016/3816/2015GH |

| 70048142 | 1 | WINCH | 3016/3816/2015GH |

| 70143670 | 2 | WINCH | 3016/3816/2015GH |

| 72531836 | 1 | INSTALLATION KIT | 3016/3816/2015GH |

| 72531832 | 1 | INSTALLATION KIT | 3016/3816/2015GH |

| 72053377 | – | – | – |

| 72063027 | 2 | OPTION-OUTRIGGER KIT-MO/MD-6X4 | – |

| 60020124 | 1 | BASE & STABILIZER ASM | 20017 |

| 60020122 | 1 | BASE & STABILIZER ASM | 20017 |

| 60020120 | 1 | BASE & STABILIZER ASM | 20017 |

| 60020121 | 1 | BASE & STABILIZER ASM | 20017 |

| 7BF81225 | 8 | BASE & STABILIZER ASM | 20017 |

| 60020192 | 3 | INNER BOOM ASM | 20017 |

| 60020190 | 3 | INNER CYLINDER | 20017 |

| 60020189 | 2 | INNER CYLINDER | 20017 |

| 60020193 | 2 | OUTER CYLINDER | 20017 |

| 60020194 | – | OUTER CYLINDER | 20017 |

OEM: IMT/Kobelco

| Part Number | QTY | Application Site | Crane Model |

|---|---|---|---|

| 60020115 | 1 | BASE & POWER OUTRIGGER ASM | 7200/1080A |

| 60020116 | 1 | BASE & POWER OUTRIGGER ASM | 7200/1080A |

| 60020187 | 1 | BASE & POWER OUTRIGGER ASM | 7200/1080A |

| 60020188 | 1 | BASE & POWER OUTRIGGER ASM | 7200/1080A |

| 7BF81225 | 2 | MAST ASM | 7200/1080A |

| 7BF81220 | 6 | INNER BOOM ASM | 7200/1080A |

| 7BF81220 | 9 | INNER BOOM ASM | 7200/1080A |

| 7BF81025 | 4 | INNER CYLINDER | 7200/1080A |

| 7BF81220 | 4 | OUTER BOOM ASM | 7200/1080A |

| 7BF81220 | 2 | OUTER CYLINDER | 7200/1080A |

| 72063027 | 2 | OUTER CYLINDER | 7200/1080A |

| 7BF81520 | 2 | BASE & MANUAL OUTRIGGER ASM | 7200/1080A |

| 72063039 | 1 | BASE & MANUAL OUTRIGGER ASM | 7200/1080A |

| 72531826 | 1 | BASE & MANUAL OUTRIGGER ASM | 7200/1080A |

OEM: Grove

| Part Number | QTY | Application Site | Crane Model |

|---|---|---|---|

| 6207200806 | 2 | SECTION ASSEMBLY – BOOM BASE | RT60S |

| 6199000631 | – | SECTION ASSEMBLY – BOOM MID | RT60S |

| 6207180821 | 2 | – | RT60S |

| 6208120818 | 1 | HOSE SHEAVE AND REAR BOOM COVER INSTALLATION | RT60S |

| 6208120851 | 1 | JIB BOOM INSTALLATION – 24FT | RT60S |

| 6205200833 | 6 | – | RT60S |

| 6207080808 | 2 | – | RT60S |

| 7444121054 | 1 | HYDRAULIC LINES INSTALLATION | RT60S |

| 7444020156 | 1 | HYDRAULIC LINES INSTALLATION – SWING AND SWING BRAKE | RT60S |

| 7445161250 | 4 | HYDRAULIC LINES INSTALLATION – MAIN HOIST GROVE MODEL 15 | RT60S |

| 7444080456 | 1 | – | RT60S |

| 7444040256 | 1 | – | RT60S |

| 7199000399 | 1 | DRIVE INSTALLATION – TURNTABLE AND CYLINDER ASSEMBLY – 81/4″ | RT60S |

| 6200080409 | 1 | BOX ASSEMBLY – SWING | RT60S |

| 7444040150 | 1 | REEL ASSEMBLY – HOSE | RT60S |

| 6199000200 | 1 | TURNTABLE LOCK PIN INSTALLATION | RT60S |

OEM: IMT/Kobelco

| Part Number | QTY | Application Site | Crane Model |

|---|---|---|---|

| 60020115 | 1 | BASE & POWER OUTRIGGER ASM | 7200/1080A |

| 60020116 | 1 | BASE & POWER OUTRIGGER ASM | 7200/1080A |

| 60020187 | 1 | BASE & POWER OUTRIGGER ASM | 7200/1080A |

| 60020188 | 1 | BASE & POWER OUTRIGGER ASM | 7200/1080A |

| 7BF81225 | 2 | MAST ASM | 7200/1080A |

| 7BF81220 | 6 | INNER BOOM ASM | 7200/1080A |

| 7BF81220 | 9 | INNER BOOM ASM | 7200/1080A |

| 7BF81025 | 4 | INNER CYLINDER | 7200/1080A |

| 7BF81220 | 4 | OUTER BOOM ASM | 7200/1080A |

| 7BF81220 | 2 | OUTER CYLINDER | 7200/1080A |

| 72063027 | 2 | OUTER CYLINDER | 7200/1080A |

| 7BF81520 | 2 | BASE & MANUAL OUTRIGGER ASM | 7200/1080A |

| 72063039 | 1 | BASE & MANUAL OUTRIGGER ASM | 7200/1080A |

| 72531826 | 1 | BASE & MANUAL OUTRIGGER ASM | 7200/1080A |

OEM: Grove

| Part Number | QTY | Application Site | Crane Model |

|---|---|---|---|

| 6207200806 | 2 | SECTION ASSEMBLY – BOOM BASE | RT60S |

| 6199000631 | – | SECTION ASSEMBLY – BOOM MID | RT60S |

| 6207180821 | 2 | – | RT60S |

| 6208120818 | 1 | HOSE SHEAVE AND REAR BOOM COVER INSTALLATION | RT60S |

| 6208120851 | 1 | JIB BOOM INSTALLATION – 24FT | RT60S |

| 6205200833 | 6 | – | RT60S |

| 6207080808 | 2 | – | RT60S |

| 7444121054 | 1 | HYDRAULIC LINES INSTALLATION | RT60S |

| 7444020156 | 1 | HYDRAULIC LINES INSTALLATION – SWING AND SWING BRAKE | RT60S |

| 7445161250 | 4 | HYDRAULIC LINES INSTALLATION – MAIN HOIST GROVE MODEL 15 | RT60S |

| 7444080456 | 1 | – | RT60S |

| 7444040256 | 1 | – | RT60S |

| 7199000399 | 1 | DRIVE INSTALLATION – TURNTABLE AND CYLINDER ASSEMBLY – 81/4″ | RT60S |

| 6200080409 | 1 | BOX ASSEMBLY – SWING | RT60S |

| 7444040150 | 1 | REEL ASSEMBLY – HOSE | RT60S |

| 6199000200 | 1 | TURNTABLE LOCK PIN INSTALLATION | RT60S |

50000+ Types of Crane Bushings – Contact Us for Details

Crane Bushings: Features & Benefits

1. Superior Wear Resistance

- Constructed from high-strength alloys, our crane bushings offer exceptional resistance to wear, reducing downtime and prolonging equipment life.

2. Self-Lubricating Design

- The integrated self-lubricating layer ensures smooth operation, reducing the need for frequent maintenance and additional lubrication, leading to lower operational costs.

3. High Load Capacity

- Specifically designed to handle the heavy lifting requirements of cranes, our bushings maintain reliable performance under extreme loads, ensuring stable and efficient operations.

4. Dust and Dirt Resistance

- Special coatings provide enhanced protection against corrosion, dust, and other contaminants, making these bushings ideal for both indoor and outdoor crane applications.

5. Custom Manufacturing for Specific Needs

- We offer custom bushing solutions, adapting sizes, materials, and designs to meet your specific requirements and equipment specifications.

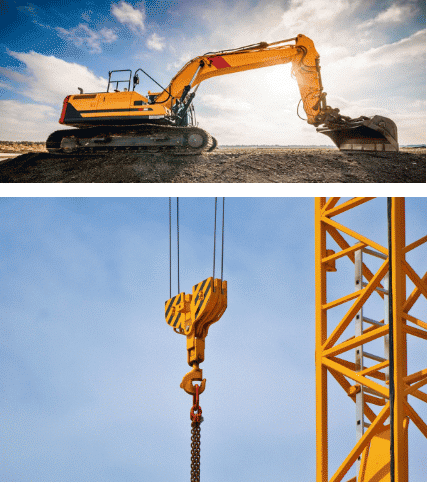

Crane Bushings: Applications

- Compatible with Major Crane Brands

- Our crane bushings are designed to fit a wide range of crane types and brands, including:

- Liebherr

- Tadano

- Manitowoc

- Terex

- Grove

- Konecranes

- Sany

- XCMG

- Zoomlion

- Link-Belt

- Demag

- Kobelco

- Palfinger

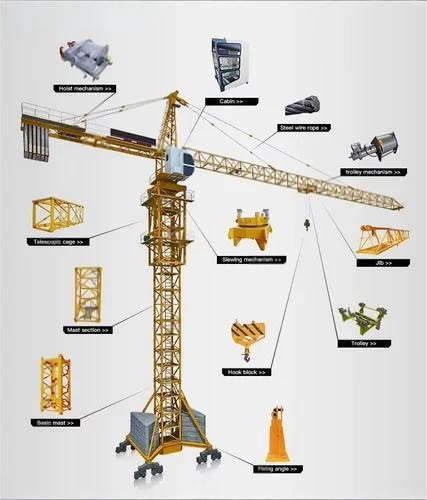

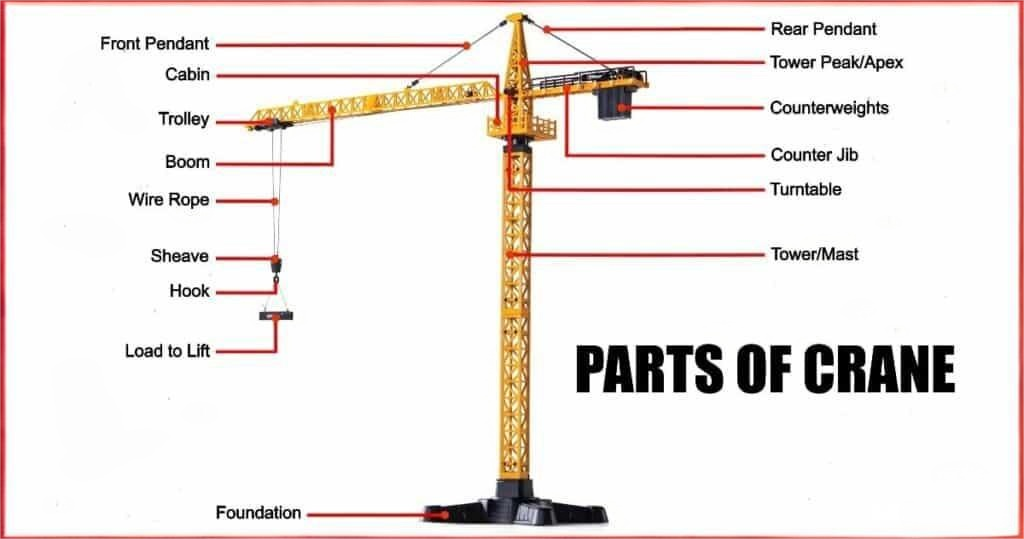

- From tower cranes and mobile cranes to overhead cranes, our bushings ensure stable lifting operations and reduced wear in critical joints and components.

- Our crane bushings are designed to fit a wide range of crane types and brands, including:

Crane Bushings: Customer Feedback

Crane Bushings: The Complete Guide to Smoother, Safer, and More Cost-Effective Lifting Operations

A single failed $50 bushing once grounded a $5 million container crane for 72 hours, racking up over $200,000 in operational losses and emergency repair costs.

From the colossal slewing rings that allow a tower crane to rotate to the intricate pivot points in a mobile crane’s hydraulic outriggers, bushings are the silent, unseen workhorses of the industry. These simple yet critical components are the linchpins of crane motion, tasked with the monumental job of reducing friction, managing immense loads, and ensuring precise, safe movement day in and day out. This guide delves into the world of crane bushings, explaining their function, types, selection criteria, and how choosing the right one—like those from MYWAY—can transform your equipment’s performance and your bottom line.

Crane Bushings 101: The Unsung Heroes of Heavy Lifting

What exactly is a crane bushing? At its core, a bushing, also known as a plain bearing or sleeve bearing, is a cylindrical component inserted into a housing to provide a smooth, low-friction surface for a rotating or sliding shaft or pin. In the muscular world of cranes, they are the shock-absorbing, wear-managing interfaces at nearly every joint and pivot point.

Their primary roles are multifaceted:

Friction and Wear Reduction: They prevent direct, destructive metal-to-metal contact between moving parts, drastically reducing wear on more expensive components like pins and shafts.

Load Support and Distribution: They absorb and distribute radial and axial forces—the crushing weights and side pressures experienced during lifts.

Vibration Dampening and Noise Reduction: By cushioning movements, they contribute to smoother, quieter, and less stressful operation for both the machine and the operator.

Contamination Control: In systems like hydraulic cylinders, specially designed bushings can act as a first line of defense, keeping abrasive particles away from sensitive seals.

Understanding these functions is key to appreciating why the correct bushing is not a generic spare part but a precision-engineered component critical to uptime, safety, and total cost of ownership.

The Great Bushing Divide: Traditional vs. Self-Lubricating

The most significant evolution in bushing technology has been the move from traditional designs to self-lubricating solutions. The choice between them fundamentally impacts your maintenance schedule and operational costs.

Traditional (Grease-Lubricated) Bushings

These are typically made from metals like bronze or steel and require a consistent regimen of manual greasing. This external lubrication creates a film that separates the moving surfaces. While initially cheaper and suitable for many applications, they come with hidden burdens: scheduled downtime for lubrication, labor costs, the risk of contamination from grease attracting dirt, and the potential for environmental pollution from grease leaks.

Self-Lubricating Bushings

These are engineered to provide their own lubrication continuously. This is achieved through materials like PTFE (Teflon), graphite, or other solid lubricants embedded within their structure (e.g., in a polymer matrix or as plugs in a metal backing). As the bushing operates, a thin, protective transfer film is created on the mating surface.

The contrast is clear:

| Aspect | Traditional Greased Bushings | Self-Lubricating Bushings |

|---|---|---|

| Maintenance | High (Regular greasing required) | Very Low to None |

| Downtime | Increased for maintenance | Maximized Uptime |

| Contamination Risk | High (Grease attracts dirt) | Low |

| Environmental Impact | Possible grease leakage | Clean, no leakage |

| Lifetime Cost | Higher (Labor, grease, failures) | Lower Total Cost of Ownership |

For modern operations prioritizing minimal maintenance and maximum reliability, self-lubricating bushings often present the superior long-term value.

Material Science: Choosing the Right Bushing for the Job

Selecting a bushing material is a balancing act between load, speed, environment, and cost. Here are the most common types found in cranes:

1. Sintered Bronze (Oil-Impregnated)

What it is: Powdered bronze sintered into shape, with oil stored in its porous structure.

Best for: Medium-load, oscillating motions like boom pivots. It offers a good balance of strength and self-lubrication but can exhaust its oil supply under extreme conditions.

2. Polymer-Based (PTFE, Nylon, UHMW)

What it is: Bushings made from high-performance engineering plastics, often with added lubricants.

Best for: Light to medium-duty, corrosion-prone applications like control linkages, cab controls, or environments with chemical or saltwater exposure. They are lightweight, quiet, and corrosion-proof.

3. Metal-Polymer Composite (e.g., Steel Backed with PTFE)

What it is: A robust, multi-layer design: a steel shell for high load capacity and a sintered bronze layer bonded to a low-friction PTFE or acetal lining.

Best for: Heavy-duty, high-load, low-speed applications where traditional lubrication is difficult. Think boom foot pins, sheave pins, and critical pivot points on mobile and tower cranes. This is a premier choice for demanding crane applications.

4. Fiber-Reinforced Composite

What it is: A blend of epoxy resins reinforced with fibers (like glass or carbon) and solid lubricants.

Best for: Extreme environments—exceptionally high loads, submerged applications, or where severe contamination is present. They handle misalignment well and are incredibly durable.

The MYWAY Advantage: Engineered for the Demand

At MYWAY, we understand that a crane is only as reliable as its most stressed component. Our bushing solutions are not just replacements; they are performance upgrades engineered for the real world.

We specialize in advanced metal-polymer composite and fiber-reinforced composite bushings that are specifically designed to meet the brutal demands of the crane industry. Our products are built to deliver:

Unmatched Durability: Engineered to withstand the high static and dynamic loads of lifting, extending the life of your entire pin joint assembly.

Maintenance-Free Operation: With premium, embedded solid lubricants, our bushings eliminate the cost, downtime, and mess of manual greasing.

Performance in Harsh Conditions: Whether it’s dust at a construction site, moisture at a port, or temperature swings, our materials are selected for resilience.

Cost Efficiency: By reducing downtime, eliminating lubrication labor and materials, and protecting more expensive components, a MYWAY bushing lowers your total operating cost.

We don’t just sell bushings; we provide application-specific solutions. Our engineering support can help you select or customize the perfect bushing for your specific crane model, from the slewing ring to the jib tip, ensuring optimal performance and longevity.

The Practical Guide: Selection, Installation, and Longevity

Choosing the right bushing is a technical decision. Follow this framework:

Analyze the Application: Identify the load (radial and axial), motion type (rotation, oscillation), speed, and environmental factors (temperature, contaminants).

Measure Precisely: Accurate measurements of the housing bore, shaft/pin diameter, and required width are non-negotiable for a proper fit.

Prioritize Key Properties: For most crane joints, load capacity, wear resistance, and need for external lubrication are the top priorities.

Install with Care: Ensure the housing and shaft are clean, deburred, and properly aligned. Press the bushing in squarely—never hammer it directly—using the correct tools. For self-lubricating types, they are typically installed dry.

Monitor and Maintain: Even self-lubricating bushings require periodic visual inspection for excessive wear, cracking, or extrusion. A well-chosen and installed MYWAY bushing will provide a long, predictable service life with minimal attention.

Crane bushings are foundational to safe, efficient, and profitable operations. Moving from a view of them as simple wear items to recognizing them as precision performance components is the first step toward improving your equipment’s reliability. By understanding the types, materials, and selection criteria—and by partnering with a focused manufacturer like MYWAY—you can make choices that reduce downtime, lower costs, and keep your cranes lifting smoothly for years to come.

Ready to eliminate lubrication headaches and specify bushings built for the long haul? Contact the MYWAY engineering team today for a consultation on your specific application.

FAQ: Your Crane Bushing Questions Answered

Q1: How often should I replace my crane’s bushings?

There’s no universal interval. Replacement should be based on regular inspection during routine maintenance. Look for signs of excessive wear (visible grooves, increased clearance), cracking, corrosion, or any change in the crane’s movement (e.g., increased slack or “stick-slip” motion). Using high-quality self-lubricating bushings can dramatically extend replacement intervals.

Q2: Can I replace a traditional bronze bushing with a self-lubricating one?

In the vast majority of cases, yes, and it is often a recommended upgrade. Ensure the new bushing has the same dimensional specifications (ID, OD, length) and a static load capacity rating equal to or greater than the original. This swap can immediately reduce future maintenance.

Q3: Are self-lubricating bushings more expensive?

Their initial purchase price is often higher. However, when you calculate the Total Cost of Ownership (TCO)—factoring in eliminated grease, saved labor hours, reduced downtime, and extended component life—self-lubricating bushings like those from MYWAY almost always prove to be the more economical choice over the long term.

Q4: My crane operates in a very wet/coastal environment. What bushing is best?

For wet or corrosive saltwater environments, polymer-based or fiber-reinforced composite bushings are excellent choices. Materials like PTFE composites or glass-reinforced composites offer superb corrosion resistance and are unaffected by water, unlike metals that can corrode or oil-impregnated bushings that can degrade.

Q5: How do I get the right MYWAY bushing for my specific crane?

Providing us with your crane make, model, and the specific component location (e.g., “lower boom foot pin, left side”) is the best start. Even better, provide the OEM part number you are replacing or precise dimensional drawings. Our technical team will match you with the optimal MYWAY solution for performance and value.