Recent Posts

Aluminium Bronze: The Ultimate Engineering Alloy for Demanding Applications

Why This Super Alloy Should Be Your First Choice for Bushings and Bearings

In the world of industrial machinery and marine engineering, component failure is not an option. The relentless forces of corrosion, friction, and high loads demand materials that are not just adequate, but exceptional. This is where aluminium bronze stands apart. Far from being just another copper alloy, aluminium bronze represents a pinnacle of material engineering, offering a suite of properties so versatile and robust that it is often the first and only logical choice for the most demanding applications.

For engineers and procurement specialists navigating specifications for bushings, bearings, and wear plates, understanding the unique advantages of aluminium bronze is key to ensuring longevity, reliability, and cost-effectiveness. Let’s delve into what makes this alloy a global industry standard and how MYWAY Bushings leverages its power to deliver superior components.

Table of Contents

1. The Defining Properties: More Than Just Corrosion Resistance

Aluminium bronze is a family of copper-based alloys where aluminium (typically between 5% and 14%) serves as the primary alloying element. This combination creates a material whose whole is far greater than the sum of its parts. While its renowned resistance to corrosion—especially in seawater and chemical environments—is a flagship feature, its true value lies in a balanced portfolio of mechanical strengths.

Imagine a material that possesses the corrosion-fighting prowess of stainless steel in marine settings, the high strength and hardness of low-alloy steels, and the excellent wear and galling resistance necessary for bearing surfaces. Aluminium bronze does exactly that. It maintains its strength over a wide temperature range, exhibits good fatigue and creep resistance, and remains ductile even at sub-zero temperatures. For components like bushings that must withstand continuous stress, this translates directly into extended service life and reduced downtime.

2. A Material for Every Challenge: Key Applications Across Industries

The exceptional blend of properties in aluminium bronze makes it indispensable across a broad industrial spectrum. Its application is a direct response to specific, harsh operational challenges.

Marine & Offshore: This is perhaps the classic domain of aluminium bronze. Components such as propellers, pump impellers, shaft bushings, and valve seats are constantly attacked by saltwater. Aluminium bronze not only resists this corrosion but also stands up to cavitation erosion and biofouling, making it a cornerstone for shipbuilding and offshore platforms.

Oil, Gas & Chemical Processing: In these sectors, safety and durability are paramount. Certain aluminium bronze alloys are non-sparking, a critical safety feature for equipment used in explosive atmospheres. Furthermore, their resistance to a variety of acids, alkalis, and saline solutions makes them ideal for pump components, valve trim, and fasteners in processing plants.

Heavy Industry & Power Generation: Where high loads and significant wear are daily realities—such as in steel mill equipment, heavy-duty gear bushings, and turbine components—the high load-bearing capacity and wear resistance of aluminium bronze ensure reliable performance.

Aerospace and Automotive: Demanding applications in landing gear components, bearings, and high-strength fasteners benefit from the alloy’s reliable performance under stress and in variable environments.

This wide applicability is reflected in a consistently growing market. Industry analysis projects the global aluminium bronze market to grow steadily, driven by ongoing demand from these core sectors.

3. Navigating the Alloy Families: Choosing the Right Grade

Not all aluminium bronzes are the same. The family is divided into several key types, each optimized for different manufacturing processes and performance profiles:

| Alloy Type | Key Characteristics | Typical Use Cases |

|---|---|---|

| Single-Phase (Alpha) Alloys (e.g., C95200) | Excellent ductility and cold workability; good corrosion resistance. | Sheet, strip, tubing, forgings for chemical plant equipment. |

| Duplex (Alpha-Beta) Alloys (e.g., C95400) | Higher strength and hardness; good castability and pressure tightness. | Most common for cast bushings & bearings, gears, pump bodies. |

| Nickel-Aluminium Bronzes (e.g., C95500, C95800) | Superior strength, corrosion fatigue resistance, and elevated temperature stability. | High-strength marine propellers, aircraft landing gear bushings, heavy-duty bearings. |

| Manganese-Aluminium Bronzes | Excellent castability, good shock and cavitation resistance. | Large, complex castings like propellers and high-strength structural marine components. |

For bushings and plain bearings, the C95400 (CuAl10Fe3) alloy is frequently the standard choice. It provides an outstanding balance of wear resistance, compressive strength, and corrosion resistance, making it suitable for a vast array of heavy-duty, high-load situations.

4. Beyond the Base Alloy: Advanced Bushing Solutions

The inherent properties of aluminium bronze can be further enhanced through intelligent design to meet specific operational challenges. Modern bushing solutions often incorporate advanced features:

Self-Lubricating/Grease Groove Designs: For applications where maintenance access is difficult or where “lubricated-for-life” operation is desired, bushings can be designed with internal grease reservoirs and distribution grooves (e.g., spiral, grid, or XY patterns).

Graphite-Plugged Options: Solid lubricants like graphite can be integrated into the bushing wall. This provides a constant, low-friction film at the bearing surface, reducing wear and preventing seizure during start-up or in poorly lubricated conditions.

Custom Geometry & Finishes: From simple sleeve bushings to complex flanged, thrust washer, or spherical designs, aluminium bronze can be precision-cast and machined to meet exact dimensional and tolerance requirements.

5. Why Source Your Aluminium Bronze Bushings from MYWAY?

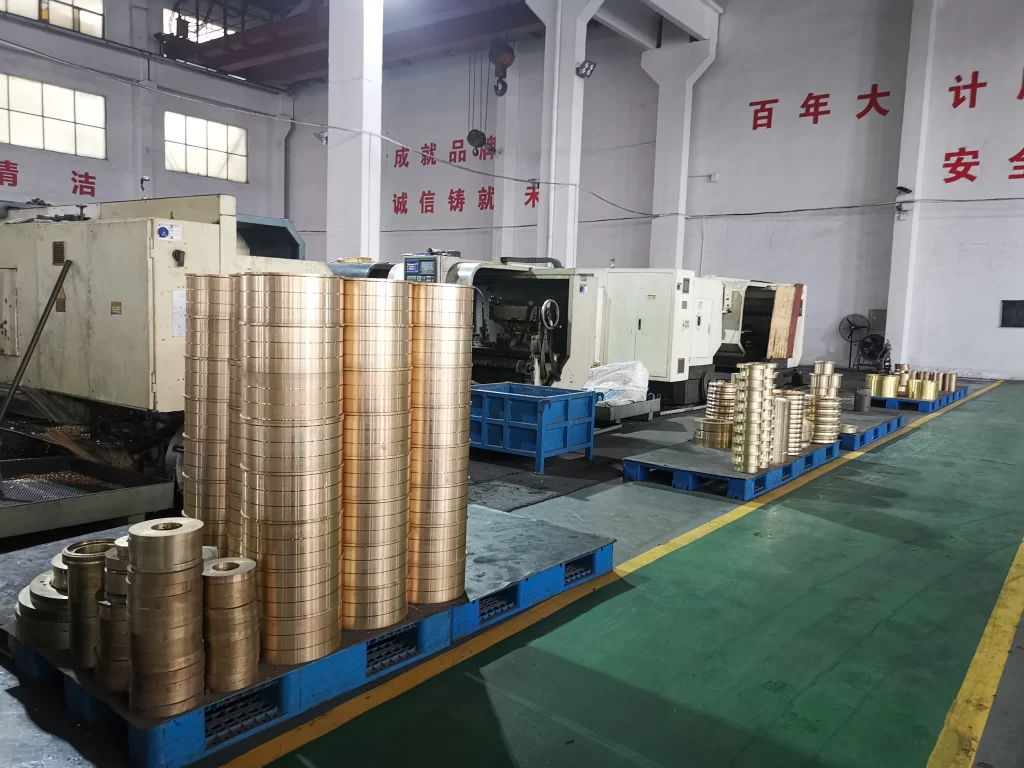

At MYWAY, we don’t just supply bushings; we provide engineered solutions. We understand that your machinery’s reliability hinges on the quality of its smallest components. Here’s how we make the difference:

Deep Material Expertise: We go beyond catalog sales. Our team understands the metallurgy of aluminium bronze and can guide you in selecting the optimal alloy (C95400, C95500, etc.) and design for your specific application—be it in a saltwater pump, a mining excavator, or a hydraulic press.

Commitment to Quality & Consistency: We adhere to strict international standards (such as ASTM). Every batch of material and every finished bushing is subject to rigorous quality control, ensuring you receive a component with predictable, reliable performance.

Custom Manufacturing Capability: Need a non-standard size, a special flange, or a unique grease groove pattern? Our foundry and machining expertise allow us to produce made-to-order components that match your blueprints precisely, eliminating compromise.

Focus on Value & Long-Term Partnership: We aim to be your trusted partner. By providing components that extend maintenance intervals and reduce unplanned stoppages, we help lower your total cost of ownership. Our efficient production and responsive service ensure you get the parts you need, when you need them.

6. Frequently Asked Questions (FAQ)

Q1: How does aluminium bronze compare to standard tin bronze (SAE 660) for bushings?

Aluminium bronze (e.g., C95400) generally offers higher tensile strength, greater hardness, and superior corrosion resistance, especially in seawater and alkaline environments. It is the preferred choice for high-load, high-wear, or corrosive applications. Tin bronze has excellent machinability and conformability and is often used for general-purpose, lower-load bushings.

Q2: Is aluminium bronze suitable for use in high-temperature environments?

Yes. Aluminium bronzes retain a significant portion of their room-temperature strength at elevated temperatures, much better than many other copper alloys. This makes them suitable for components in engines, turbines, and high-temperature processing equipment.

Q3: Can aluminium bronze bushings be used in submerged seawater applications?

Absolutely. This is one of their strongest applications. Nickel-aluminium bronze (e.g., C95800) is particularly renowned for its outstanding resistance to seawater corrosion, impingement attack, and cavitation erosion, making it a standard for naval and commercial marine hardware.

Q4: Do you offer self-lubricating options for aluminium bronze bushings?

Yes. We provide graphite-plugged aluminium bronze bushings which are ideal for situations where re-lubrication is impossible or undesirable. The graphite provides a permanent dry-lubricating layer, reducing friction and wear.

Q5: Can MYWAY produce custom or prototype bushings?

Yes, we specialize in it. Whether you need a prototype for testing or a full production run of a custom-designed bushing, our engineering and manufacturing teams can work from your drawings or samples to deliver a solution tailored to your exact needs.

Ready to specify the right bushing for your most challenging application? Don’t let component failure dictate your maintenance schedule.

Contact MYWAY today for a expert consultation and a competitive quote. Let our team help you leverage the unparalleled properties of aluminium bronze to build more durable, reliable, and efficient machinery.

Get in Touch for Your Custom Bushing Solution

100000+ Types of Bushings – Contact Us for Details