Ensuring Reliable Cold Starts: MYWAY Heavy-Duty Truck Starter Bushings

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

MYWAY Starter Bushings for Heavy-Duty Trucks

Starter End Plate Bushing - 1932-53 Ford Truck, 1928-66 Ford Car, 1939-64 Ford Tractor

Starter End Plate Bushing - 1932-53 Ford Truck, 1928-66 Ford Car, 1939-64 Ford Tractor Features: • Brass - 5/8" I.D. x 3/4" O.D. x 9/16" Long • Installs in Starter End Plate Ford Tractor All - 1939-64 Ford Truck All - 1932-56

For 1951-1959 GMC 370 Starter Bushing SMP 56341ZCPK 1952 1953 1954 1955 1956

Application GMC 370 Starter Bushing Part Number 56341ZCPK Product Name Starter Bushing Years 1951 1952 1953 1954 1955 1956 1957 1958 1959 CS-SKU 400:56341ZCPK

labwork 2 pcs Starter Bushing Replacement for Polaris Sportsman Magnum Trail Boss Ranger 3083669

Product Dimensions : 3.54 x 2.36 x 1.02 inches; 1.13 ounces ASIN : B09STBYXBF Replacement for Polaris 300 1994-1995 Replacement for Polaris 400L 1994 Replacement for Polaris ATP 330 500 2004-2005 Replacement for Polaris Big-Boss 250 1989-1992 Replacement for Polaris Big-Boss 300 1993 Replacement for Polaris Big-Boss 350L 1994 Replacement for Polaris Big-Boss 400L 1993-1996 Replacement for Polaris Big-Boss 500 1998

Starter Bushings Briggs & Stratton Bushings ONLY part of Briggs 395538 Brush Kit

Replaces: PM395538 Fits the following Starter part numbers: BRIGGS & STRATTON 5406, 390838, 391423, 392749, 393499, 394805, 396306, 491766, 497401, 497525, 497594, 497595, 497596, 498148, 593934, 693054, 690658, 693551, 693552, 695479, 808106 JOHN DEERE AM122337, AM37352, AM39137, LG497595, MIU13772, SE501880, LG693551, SE501848

6V TO 12V STARTER BUSHING

Part Number: 00-4027-0 Fitment: Allows a 12-volt starter to work with a 6-volt transmission (1966 and earlier) Material: Brass Outer Diameter: 0.650" (fits 6-volt transmission) Inner Diameter: 0.425" (fits 12-volt starter shaft) Replaces OEM Part: 111 301 155 Sold As: Each This bushing is essential for adapting starter systems in classic VW models, ensuring proper fitment and reliable operation. 4027 - Bushing, Bronze, 12-Volt Starter to 6-Volt Transaxle

XRC TWO STROKE STARTER BUSHINGS BY TOKYO OFFROAD

XRC2020 XRC2016 XRC2017 XRC2019 (4pcs Standard) (2pcs Standard) (2pcs Long) 2018*Carb 2020KTM&Husky TPI 2017,2018*CarbKTM&Husky Upto2016CarbKTM&Husky (250&300) (250&300) (150,2508300) (250&300) 2019*KTM&Husky TPI 2019*KTM&HuskyTPI 2018TPI(250&300) KTMFreeride 250R (250&300) (250&300)

Customized Stainless Steel Sleeve Auto Electric Motor Starter Bushing

Material stainless steel Type Sleeve Inside Diameter Tolerance ±0.01 mm Lubrication Oil Outside Diameter Tolerance ±0.01 mm Overall Length 50MM Model Number BUSHING Bush types Tube Size 14*16*12mm etc Customized Size Product Material Stainless Steel,Brass,Aluminum,Carbon steel,copper

Truck Parts Starter Moter Bush Kit TCB118 Used for Lucas M45 M50 79-92104

weight (kg) 0.1 KG OEM 1887955M91 - TCB118 Model number KBS1053 Manufacturer Part Number BUH665 Starter Motor Type: M50 Weight 0.072kg Quality High-quality

DAF KB0101 Auto Truck Starter Motor Bronze Bush EK14001 Self-Lubricating Bearing Bushing EK14011 Sliding Type PMSNT Class 1

Precision Rating Class 1 Applicable Industries Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company Model Number KB0101 Type Sliding Part 1 2000301015 Part 2 2000301016

10 12 15 16 18 24 25mm Oil-impregnated Sintered Bushing,Auto Car Truck Starter Motor Cover Bush Bearing

Applicable Industries Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Home Use, Retail, Food Shop, Construction works , Energy & Mining, Gearbox, Fan Motor, Home Device Material Bronze, Copper, Brass, Iron, PTFE Type Spherical Model Number FZ,FB090,FB092,WB702,WB802,WB800,WB700,JDB,FU Lubricating Oil impregnated, Self lubricating Oil Rate >=18% Type

Truck Tractor Construction Machinery Starting Motor Engine Main Shaft Slide Sleeve JFB Steel Bronze Bimetal Bushings

Applicable Industries Manufacturing Plant, Machinery Repair Shops, Construction works , Energy & Mining Material Steel + CuPb10Sn10 Type Sleeve Inside Diameter Tolerance as required Lubrication Oil Outside Diameter Tolerance as required Overall Length as required Model Number TCB301 Brand Name TEHCO Product name Factory Supply Bimetal Sleeve Trunnion Bearing Bushing for Hino Truck Bush types Sleeve,Flanged,Washer Certification ISO9001, TS16949 Processing method CNC processing

AUTO-Bushings for hino Truck Parts M 125x135x83

Model Number M125x135x83 Product name AUTO-Bushings weight 1.2KG Material Steel Quality 100%tested MOQ 1 Piece SIZE M125x135x83 Single gross weight 1.300 kg

10000+ Types of Heavy-Duty Truck Starter Bushings – Contact Us for Details

| Component Category | Specific Type / Model | Product Series Name |

| Starter Motor | Bushing (Copper/Bronze) | Graphite-Embedded (e.g., Metal Graphite Brush) |

The Silent Killer of Truck Starters: How a Wrong Bushing Can Cost You Thousands

For fleet managers and heavy-duty mechanics, a truck that refuses to start is more than an inconvenience—it’s a direct hit to the bottom line. While technicians often blame the battery, solenoid, or starter motor itself, a critical and frequently overlooked component is the humble starter bushing. This small, cylindrical sleeve bearing is the guardian of your starter motor’s alignment and longevity. Ignoring it can lead to catastrophic failure, as evidenced by countless real-world repair headaches.

This article dives deep into the critical role of the starter bushing in truck applications, explains how the wrong bushing causes expensive failures, and provides a clear guide to selecting the right component for reliable cold starts and reduced downtime.

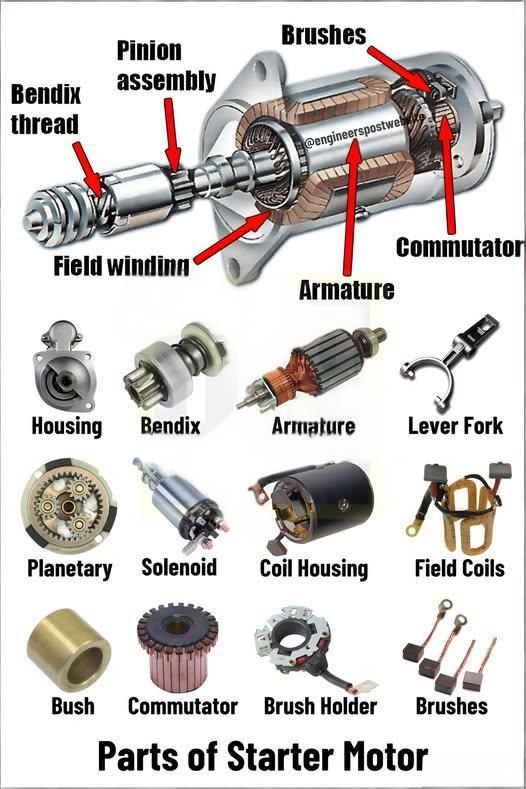

Understanding the Truck Starter Motor’s Extreme Duty

A truck starter motor is a powerhouse designed for a brutal job. It must convert electrical energy from the battery into sufficient mechanical force to rotate a large-displacement diesel engine’s flywheel, overcoming immense compression pressures. This process subjects the starter, especially its drive gear and shaft, to tremendous radial and axial forces.

The starter bushing (or bearing) is installed in the starter mounting nose or the transmission bell housing. Its core functions are:

Maintain Precise Alignment: It ensures the starter pinion gear engages perfectly with the flywheel ring gear.

Absorb Radial Loads: It supports the weight and rotational forces of the starter armature shaft.

Reduce Friction & Wear: It provides a smooth, durable surface for the shaft to rotate against, preventing metal-on-metal contact.

When this component fails or is incorrect, the entire starting system is compromised.

How the Wrong Bushing Leads to Catastrophic Failure: Real-World Lessons

Online mechanic forums and repair logs are filled with stories that trace major starter failures back to this small part. Here are the most common failure modes stemming from an incorrect or worn bushing:

Misalignment and Grinding: As several mechanics noted in discussions, using a bushing for a 6-volt starter in a 12-volt application (or vice-versa) often leads to a slight but critical misalignment. This causes the pinion gear to grind against the flywheel, producing metal shavings and eventually destroying both gears. One user described the result as the flywheel having “minced it up”.

Bushing Walk-Out and Destruction: Improper installation or excessive clearance can cause the entire bushing to be forced out of its bore when the starter engages. As one mechanic shared, “I… just pushed the bushing out the other side and the flywheel minced it up”. This leads to immediate, catastrophic failure.

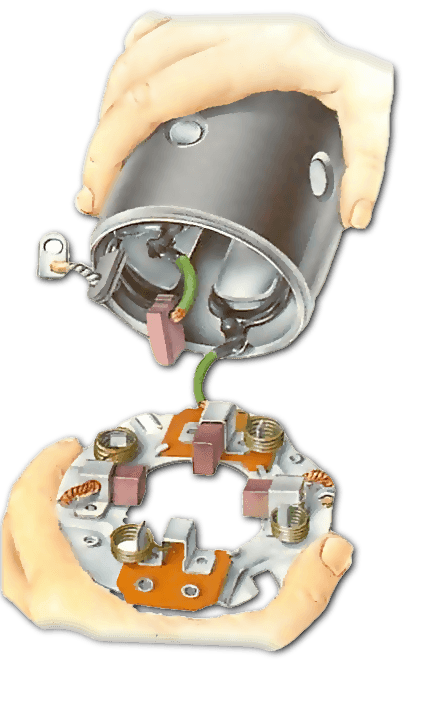

Increased Drag and Power Loss: A worn-out or poorly lubricated bushing creates excessive friction. This parasitic drag steals power from the starter motor, causing slow cranking, especially in cold weather. As an engineering source notes, worn bushes contribute to “more current draw” and weakness, straining the battery and electrical system.

Shaft Seizure and Starter Lock-Up: In severe cases, a completely failed bushing can cause the armature shaft to seize or bind. This may result in the starter staying engaged with the flywheel while the engine is running—a condition one mechanic called “kind of unusual” but devastating, as it can destroy the starter drive and ring gear.

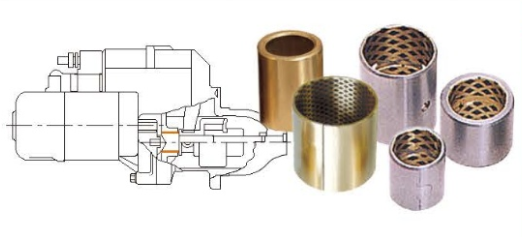

Choosing the Right Bushing: A Material and Specification Guide

Selecting a bushing isn’t a one-size-fits-all task. The correct choice depends on material properties and precise dimensions.

Common Bushing Materials & Their Fit:

| Material Type | Key Characteristics | Ideal Application |

|---|---|---|

| Sintered Bronze (Oil-Impregnated) | Traditional material, good wear resistance, self-lubricating to a degree. Requires proper soaking in oil before installation. | Standard replacement for many OEM applications where regular lubrication is possible. |

| Metal-Polymer Composites | Advanced self-lubricating materials. Lower friction, excellent dry-run capability, resistant to contamination. Often used in maintenance-free designs. | Modern truck applications, harsh environments, or where regular maintenance is difficult. |

| Brass/Bronze Alloys | Good machinability and corrosion resistance. Performance heavily depends on exact alloy composition and porosity. | Common in older models and specific OEM designs. Must be the correct specified alloy. |

Critical Selection Checklist:

To avoid the “wrong bushing” trap, always verify:

Voltage & Model Specification: Confirm if the starter is for a 6V, 12V, or 24V system and the exact truck/engine model.

Precise Dimensions: Measure the Inside Diameter (ID), Outside Diameter (OD), and Length (L) of the old bushing with calipers. Even a 0.5mm error can cause misalignment.

Material & Lubrication Requirements: Follow OEM guidelines. Some bushings require pre-soaking in gear oil, while others are coated or composite and installed dry.

Installation Context: Determine if it’s a starter nose bushing or a transmission housing bushing, as they differ.

The MYWAY Advantage: Engineering Reliability for Heavy-Duty Starts

At MYWAY, we understand that a starter bushing is a critical wear component, not just a simple spacer. Our DU/SF-1 series self-lubricating bushings are engineered to meet the extreme demands of truck starting systems.

Our bushings are constructed with a robust three-layer metal-polymer composite design for superior performance:

High-Strength Copper Substrate: Provides excellent load-bearing capacity and superior heat dissipation to manage the thermal stress of high-torque starts.

Intermediate Porous Bronze Layer: Ensures a permanent, mechanical bond between the substrate and the sliding layer.

PTFE-Based Sliding Layer: A specially modified PTFE mixture forms a protective, low-friction transfer film on the shaft during operation, enabling smooth engagement and long service life with minimal maintenance.

We offer both standard specifications for common truck models and fully customized solutions. Our engineering team can develop bushings to your exact ID, OD, length, and material requirements, ensuring a perfect fit and optimal performance for your specific application.

Tired of repeat starter failures and unnecessary downtime?

Don’t let a $20 bushing cause a $2,000 repair. Upgrade to precision-engineered, reliable components.

Contact MYWAY today for a technical consultation or a competitive quote. Let us provide you with the right bushing solution for guaranteed starts.

Frequently Asked Questions (FAQs)

Q: Can I just grease any starter bushing during installation?

A: No. Oil-impregnated sintered bronze bushings must be soaked in clean engine oil before installation. However, many modern self-lubricating composite bushings (like MYWAY’s DU/SF-1) are designed to be installed dry. Applying grease to these can clog their porous structure and hinder performance. Always follow the manufacturer’s instructions.

Q: How can I tell if my starter bushing is worn out?

A: Key signs include a high-pitched whining or grinding noise during cranking (indicating misalignment), slow or labored cranking (excessive drag), or visible wobble of the starter armature shaft. Metal shavings around the starter nose are a definitive red flag.

Q: Is it worth repairing a starter, or should I just replace the whole unit?

A: For many heavy-duty trucks, rebuilding the starter with new high-quality components—including the bushing—is a cost-effective and reliable option. It allows you to upgrade to more durable parts than some low-cost replacement starters might contain. The decision often depends on the core condition of the starter’s armature and field coils.

Q: MYWAY mentions custom solutions. What would I need to provide for a quote?

A: To provide an accurate custom bushing quote, we typically need: 1) Detailed dimensional drawings or precise measurements (ID, OD, Length), 2) Your application details (truck make/model, engine, starter part number), 3) Information on load, speed, and operating environment. Our engineering team will handle the rest.