MYWAY Bushing: Automotive Engine Connecting Rod bushing Solutions

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Automotive » Automotive Connecting Rod Bushings

MYWAY Automotive Engine Connecting Rod bushing

Connecting Rod Bushing 3364862273

Connecting rod bushings Audi 1588-1716-1781-2144-2226cc ACL

Connecting rod bushings Audi 1588-1716-1781-2144-2226cc ACL The big end bush is a piece metal tube pressed into the connecting rod head, adjacent to the piston pin. Works in extreme conditions as a sliding bearing. Use of oil of wrong viscosity, oil deficiency, low pressure in the lubrication system, too high load on cold engine, neglect of oil change intervals or wrong mounting of the connecting rod cause excessive load on the bushings, their faster wear.

4DQ7 Connecting Rod Bushing Suitable for Mitsubishi Engine Part

Product Name: Con Rod Bush Higher-quality: Using high-quality materials and manufacturing processes to ensure its reliability, durability and consistent performance. Application: Compatible for Mitsubishi 4DQ7

1372504 Auto Parts Engine Parts Connecting Rod Bushing Bb3q-6207-AA for Transit Ranger 2.2L

Model NO. 1372504/BB3Q-6207-AA Engine Type Diesel Car Fitment for Ford Transit Engine Puma 2.2 Specification OE Standard Size

Bushes for connecting rod (4 units) VW T2 1.7L, 1.8L, 2.0L (08/1971-07/1979) and VW T3 2.0L (06/1979-12/1982)

For 1700 CC, 1800 CC and 2000 CC petrol engines of the VW T2 between 08/1971 and 07/1979 and VW T3 2000 CC between 06/1979 and 12/1982.

For 1700 CC, 1800 CC and 2000 CC petrol engines of the VW T2 between 08/1971 and 07/1979 and VW T3 2000 CC between 06/1979 and 12/1982.

BC Brian Crower connecting rod bushings fit the 4G63 Evo 1-9, 1G/2G DSM, and GVR4, VR38DETT R35 GTR, V10 R8/ Lambroghini, FA20/ EJ20/ EJ25 Subaru WRX/ Sti. Offered in various diameters. BC Brian Crower connecting rod bushings are available for purchase as replacements to existing bushings that come installed in all new BC connecting rods. Manufactured from Aluminum/Silicone/Bronze material.

1 Connecting rod bushing for Type 4 engine: 1.7, 1.8, 2.0 L

Details about : 1 Connecting rod bushing for Type 4 engine: 1.7, 1.8, 2.0 L Connecting rod bushing 23.5 - 24 mm Quality equivalent to the original For Combi, Transporter T25/T3, Porsche 914 type 4 engines: 1700, 1800, 2000cc The connecting rod bushings are press-mounted, drilled when in place (oil holes), and slightly bored out again if need be so that the axis slides smoothly without play Original reference OEM: 021 105 431A

5257363 Engine Connecting Rod Bushing Isf3.8 Qsf3.8 Copper Sleeve for Foton Cummins

Model NO. 5257363 Certification ISO 9001 Engine Type Diesel Material Aluminum OEM Support Specification Standard size

Connecting Rod Bushing 11241278209

BMW E28 528e M20 2.7L Use vehicle selector to confirm fitment BMW E30 318i M10 1.8L Use vehicle selector to confirm fitment BMW E30 318i M42 1.8L Use vehicle selector to confirm fitment BMW E30 318is M42 1.8L Use vehicle selector to confirm fitment BMW E30 325e M20 2.7L Use vehicle selector to confirm fitment BMW E30 325i M20 2.5L Use vehicle selector to confirm fitment BMW E30 325ix M20 2.5L Use vehicle selector to confirm fitment

VW Connecting Rod Bushing

The VW Connecting Rod Bushing installs by first pressing out the old bushing from a stock connecting rod. Then, chamfer one end of the new bushing, clean it up, apply a strong thread locker to the outside of the bushing and press it in place. The oil hole must be drilled in the new bushing, then it can be honed out to accept the wrist pin bushing. Then check and correct the alignment as needed and you're done. We recommend leaving the whole process up to a qualified machine shop, or purchasing a new set of rods that already have the bushing installed.

M129 M108 M180 M127 piston pin connecting rod bushing

Categories: GLYCO, M108, M127, M129, M180, NOS(New Old Stock), UNIMOG, W105, W108, W110, W111, W113, W114, W128, W180, W187 、GLYCO BEARING, glyco bearing catalogue, GLYCO bearing set, glyco rod bearing set standard, M108 engine parts, M108 parts, M108 spare parts, M129 M108 M180 M127 piston pin connecting rod bushing set of 6 MERCEDES-BENZ #108 038 03 50 MERCEDES-BENZ #A 108 038 03 50 KOLBENSCHMIDT #87 247 690 1080380350 GLYCO #55-2533

VWC-111-105-433-SET - (111105433) - OE QUALITY REPLACEMENT - SET OF 4 CONNECTING ROD BUSHINGS - 40HP 1200CC BEETLE STYLE ENGINES

Connecting Rod Bushing at best price in Ahmedabad by Omkar Motors | ID: 3364862273

Diesel Engine Spare Parts for Cummins Qsb6.7 4891178 Connecting Rod Bushing

Model NO. 4891178 Engine Type V-Type Engine Number of Cylinders Four Cylinder Start Electric Start Part Name Connecting Rod Bearing Material Code 4891178 Standard Standard, Nonstandard Material Steel

10000+ Types of Automotive Engine Connecting Rod bushings – Contact Us for Details

| Component Category | Specific Type / Model |

| Automotive Engine Connecting Rod Bushings | Brass Bushing, Bimetal Bushing |

Automotive Engine Connecting Rod Bushings: Selection, Performance, and Durability

Introduction

Nestled deep within the heart of your car’s engine lies a component that operates under immense pressure yet is fundamental to smooth performance: the connecting rod bushing. Often overshadowed by pistons and crankshafts, this small bearing is the critical pivot point linking the piston to the crankshaft. It withstands explosive combustion forces, rapid directional changes, and intense friction every second of operation. Choosing the right connecting rod bushing isn’t just a maintenance task; it’s a strategic decision impacting engine efficiency, longevity, and reliability. This guide cuts through the complexity, offering a clear roadmap to understanding, selecting, and optimizing this essential engine component for peak performance.

What is a Connecting Rod Bushing and Why Does It Matter?

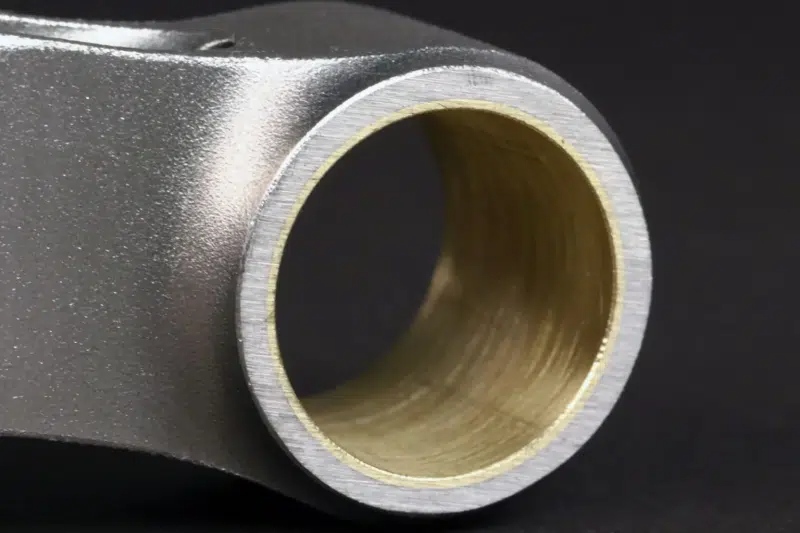

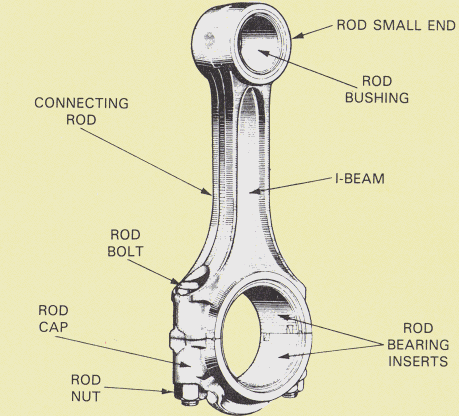

The connecting rod (con-rod) acts as the engine’s crucial intermediary, converting the piston’s linear up-and-down motion into the crankshaft’s rotating motion. At the small end of this rod, where it connects to the piston via the wrist pin (gudgeon pin), sits the connecting rod bushing.

Think of it as a high-performance sleeve bearing. Its core functions are deceptively simple yet vitally important:

Friction Reduction: It provides a precision, low-friction surface for the wrist pin to rotate within, minimizing power loss and heat generation.

Load Distribution & Shock Absorption: It absorbs and distributes the tremendous cyclic loads from combustion and inertial forces, protecting both the piston and the connecting rod from excessive stress and wear.

Alignment Maintenance: It ensures precise alignment between the piston and connecting rod, which is critical for smooth operation and preventing abnormal wear patterns.

A failure here is catastrophic. Symptoms of a worn or failing bushing include increased engine knock or tapping noises, loss of power, excessive oil consumption, and ultimately, engine seizure. This makes its selection and quality paramount.

Deep Dive: Materials and Types of Connecting Rod Bushings

The demanding environment of an engine cylinder requires bushings made from specialized materials. The choice directly influences performance, load capacity, and lifespan.

1. Bronze Bushings: The Traditional Workhorse

Bronze alloys have been the standard for decades due to their excellent balance of properties.

Tin Bronze (e.g., CuSn6Zn6Pb3): Known for high mechanical strength, good wear resistance, and favorable corrosion resistance. The addition of tin and other elements enhances machinability and load-bearing capacity, making it a reliable choice for many production and high-performance engines.

Aluminum Bronze: Offers superior strength and exceptional wear and corrosion resistance, often used in highly stressed or specialized applications.

Advantages: Good conformability (ability to adapt to minor misalignments), well-understood performance characteristics, and generally good heat dissipation.

Considerations: Typically requires a robust lubrication film and may have a lower load capacity compared to advanced bi-metal options under extreme conditions.

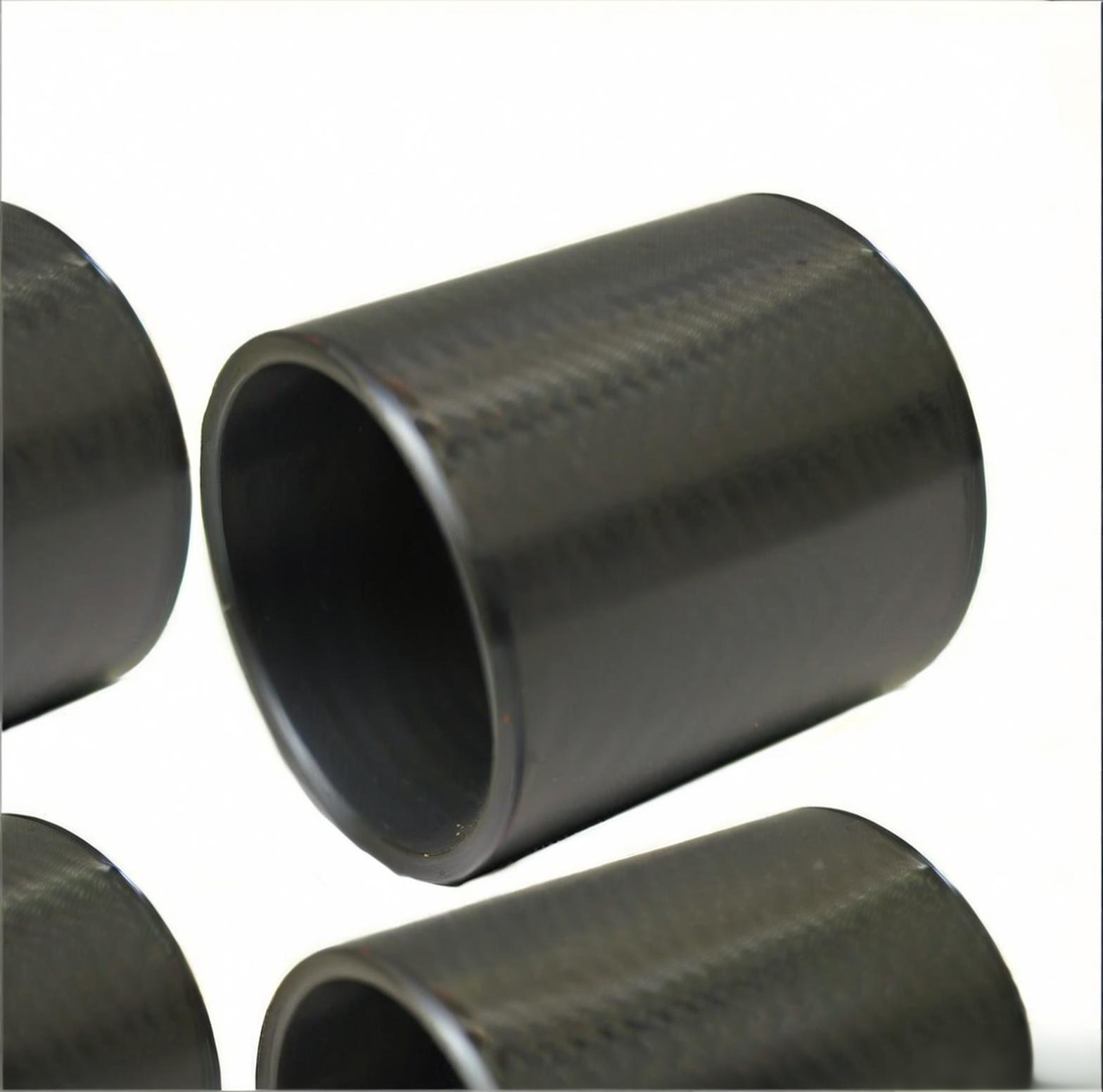

2. Bi-Metal (Steel-Backed) Bushings: The Modern Standard for Performance

This is where engineering meets innovation. Bi-metal bushings are a composite material, delivering the “best of both worlds.”

Construction: A strong, rigid steel backing provides structural integrity and excellent load-bearing capacity. Bonded to this is a sintered layer of a bearing alloy—commonly a copper-lead alloy (e.g., CuPb10Sn10, CuPb30) or a lead-free alternative like aluminum-tin (AlSn20Cu).

Key Advantages:

Exceptional Load Capacity: The steel back allows it to withstand the extreme pressures of modern, high-output engines.

Embeddability & Conformability: The softer bearing surface can safely embed small foreign particles, preventing shaft scoring.

Optimized for Lubrication: The sintered structure can be engineered to retain oil, and surfaces often include precision grooves or holes (like hemispherical oil dimples) to enhance oil film maintenance.

Cost-Effectiveness: Provides high performance without the cost of a solid bronze bushing.

These characteristics make bi-metal bushings, such as JF700 or JF800 series alloys, the preferred choice for most OEM automotive applications, from passenger cars to heavy-duty truck engines.

3. Specialized and Emerging Materials

Polymer-Based or Composite Liners: Used in some bi-metal designs, these offer extremely low friction and can run under marginal lubrication conditions.

Solid Lubricant-Impregnated Alloys: For extreme environments, materials are sintered with graphite or other solid lubricants, creating a self-lubricating safety net.

The Manufacturing and Quality Imperative

A bushing is only as good as its manufacturing. Key processes define its quality:

Precision Machining: Dimensional accuracy (ID, OD, wall thickness) is non-negotiable for a perfect press-fit into the connecting rod and precise clearance around the wrist pin. Tolerances are measured in microns.

Surface Engineering: The finish of the inner bore is critical for promoting oil film retention and minimizing initial wear.

Robust Bonding: For bi-metal types, the metallurgical bond between the steel back and the bearing layer must be flawless to prevent separation under load.

Heat Treatment & Finishing: Processes like tin plating are often applied to improve corrosion resistance, break-in properties, and compatibility with the mating surface.

Choosing the Right Bushing: An Engine Builder’s Checklist

Selecting a bushing isn’t about picking the “strongest” material. It’s about the right fit for the application.

Engine Application & Load: Is this for a daily driver, a high-revving race engine, or a high-torque diesel? Load profiles differ drastically.

Performance Goals: Are you prioritizing maximum durability, reduced friction for power, or longevity under stop-and-go conditions?

Material Compatibility: The bushing material must work harmoniously with your chosen wrist pin material (e.g., hardened steel, DLC-coated).

Precision Dimensions: Always refer to the engine manufacturer’s specifications for clearances. “Close enough” can lead to rapid failure.

Supplier Expertise: Source from manufacturers who understand the metallurgy and can provide consistent, certified quality.

Partner with MYWAY for Your Critical Engine Component Solutions

The journey to understanding the perfect connecting rod bushing underscores a universal truth in engineering: reliability is built on precision, material science, and meticulous attention to detail. At MYWAY, we live by this principle every day.

While the connecting rod bushing is a masterpiece of focused engineering, its core challenges—managing extreme friction, bearing shock loads, and ensuring longevity under stress—are the very same challenges we conquer for our clients across industries. MYWAY specializes in manufacturing high-performance bushings, wear plates, and custom bearing solutions for the most demanding applications in metallurgy, heavy machinery, and industrial automation.

Our expertise lies in selecting and engineering the right material for the job, whether it’s a specialized bronze alloy, a self-lubricating composite, or a high-strength steel-backed component. We bring this same commitment to precision manufacturing and problem-solving to every project.

Are you tackling a wear problem, seeking a more reliable component, or designing a new system that demands custom bearing solutions? Let’s discuss how MYWAY’s engineering-centric approach can provide the durability and performance your application requires.

Contact MYWAY today for a consultation. Let us help you build something that lasts.

FAQ: Automotive Connecting Rod Bushings

Q: How often should connecting rod bushings be replaced?

A: There’s no fixed mileage. They are typically inspected and measured during major engine rebuilds. Replacement is necessary if wear exceeds manufacturer specifications, ovality is detected, or if there is visible scoring or damage. Using contaminated oil or experiencing lubrication failure will drastically shorten their life.

Q: Can I replace a bi-metal bushing with a solid bronze one, or vice versa?

A: It is generally not recommended unless the engine is specifically designed for it or you are working with an experienced engine builder. The different materials have different expansion rates, load capacities, and required wall thicknesses/clearances. Switching can lead to improper fit, accelerated wear, or failure.

Q: What is “embedability” and why is it important?

A: Embedability refers to a bearing material’s ability to absorb tiny, hard contaminant particles (like dust) into its surface, preventing them from scratching the harder shaft (wrist pin). This is a key advantage of many bi-metal and softer bronze alloys, acting as a final defense against abrasive wear from contaminated oil.

Q: Is a tighter bushing clearance always better for performance?

A: No. Clearance is a critical engineered specification. Too tight can prevent adequate oil film formation, leading to overheating, galling, and seizure. Too loose causes excessive noise (knock), increased impact loads, and loss of oil pressure. Always follow the engine manufacturer’s or a reputable performance builder’s recommended clearance for your specific application.

Q: Do performance bushings require a special break-in procedure?

A: Often, yes. Especially with precision-machined high-performance bushings, a proper break-in procedure using non-detergent break-in oil and varying engine speeds is crucial to allow the surfaces to mate properly without generating excessive heat or wear. Always follow the bushing or engine builder’s specific break-in instructions.