Recent Posts

Tin Bronze: the Alloy That Powers Heavy Industry

From Ancient Metal to Modern Marvel

When machinery faces its toughest challenges—from the relentless pounding in a steel mill to the corrosive bite of seawater—there’s a family of alloys that has been the engineer’s trusted choice for centuries: tin bronze. More than just a historical artifact, modern tin bronzes represent the pinnacle of material science for demanding applications, combining legendary durability with critical self-lubricating properties. This guide delves into the engineering heart of these alloys, exploring why they remain indispensable and how today’s manufacturers are pushing their performance to new frontiers.

Table of Contents

1. The Core of Bronze: Copper, Tin, and Performance

At its simplest, tin bronze is a copper alloy primarily composed of copper and tin, with other elements like phosphorus added to enhance specific properties. The magic lies in the synergy between these metals. While copper provides excellent conductivity and corrosion resistance, the addition of tin (typically 8-12.5%) fundamentally transforms the material.

Solid-Solution Strengthening: Tin dissolves into the copper matrix, creating a stronger, tougher metallic structure without sacrificing too much ductility.

The Phosphorus Advantage: When deoxidized with phosphorus (0.01-0.45%), the alloy is often called phosphor bronze. Phosphorus not only cleans the melt during casting but also dramatically improves wear resistance, hardness, and fatigue resistance.

This combination yields a material profile perfectly suited for punishment: excellent corrosion resistance (especially against seawater), good fatigue strength to withstand cyclic loading, high wear resistance, and favorable machinability for creating precise components.

2. Pushing the Limits: Advanced Tin Bronze Composites

Traditional cast and wrought tin bronzes are formidable, but modern engineering demands even more. Research has focused on creating advanced tin-bronze-matrix self-lubricating composites to tackle extreme friction and wear challenges.

Scientists have developed innovative materials, such as tin-bronze-net reinforced composites, fabricated via powder metallurgy processes. These materials incorporate a reinforcing metallic net within a similar bronze matrix, leading to a significant boost in mechanical and tribological (friction and wear) behaviors. The key is excellent interfacial compatibility, which allows the composite to support higher loads and resist wear more effectively. However, studies show there is an optimal balance—too high a volume of reinforcing net can introduce defects and reduce performance.

Further innovations include adding novel Tribaloy alloy particles (like T-401) to the tin-bronze matrix. These cobalt-based intermetallic particles, dispersed during sintering, act as hard, wear-resistant phases. The result is a composite journal bearing material with superior wear resistance under poor or unlubricated conditions, while maintaining good ductility and corrosion resistance. The tribaloy particles do not chemically react with the bronze matrix, preserving the beneficial properties of both materials.

3. A Guide to Key Tin Bronze Alloys

Navigating the various designations can be complex. The following table breaks down some of the most important grades, highlighting their profiles and ideal uses.

| Common Designations | Base UNS Alloy | Key Composition (Approx.) | Engineering Profile & Typical Applications |

|---|---|---|---|

| C90300, C90500 | C90300, C90500 | Cu, ~10% Sn | General-Purpose Toughness. Excellent all-around corrosion resistance and fatigue strength for bearings, thrust washers, and pump components. |

| C90710, SAE 65, CuSn12 | C90710 | Cu, 11-12% Sn | High-Strength & Wear Resistance. The premium choice for heavy-duty worm gears, high-load bushings, and industrial gear blanks where superior strength is critical. |

| C93700, “80-10-10” | C93700 | Cu, 10% Sn, 10% Pb | High-Leaded for Machinability. Features excellent machinability and good corrosion resistance. Traditionally used for general bearings, bushings, and pressure-tight castings. |

| C94400 | C94400 | Cu, 8% Sn, 11% Pb, 0.35% P | Excellent Machinability & Castability. Known for its low strength but very good casting characteristics and corrosion resistance, used for bushings and corrosion-resistant castings. |

Note: Properties can vary based on manufacturing process (cast, sintered, wrought).

4. Contrasting Bronze: Choosing the Right Alloy for the Job

Understanding tin bronze also means knowing when it shines compared to its cousins:

Vs. Leaded Bronzes (e.g., C93200): Leaded bronzes offer fantastic machinability and embedded lubricity but lack the high fatigue and shear strength of high-tin bronzes. They are not suitable for heavy gearing.

Vs. Aluminum or Manganese Bronzes: These alloys offer very high tensile strength but can form abrasive oxides (like aluminum or zinc oxide) on mating steel surfaces over time, potentially promoting wear. High-tin bronzes form more benign, protective transfer films.

The Verdict: Tin bronze is the specialist for wear and fatigue. It is the engineer’s choice when the primary failure modes are expected to be friction, cyclical stress, and corrosion, particularly in environments like marine applications or heavy industrial machinery.

5. Where Tin Bronze Proves Its Mettle: Critical Applications

The unique property package of tin bronze makes it the undisputed champion in several high-stakes fields:

Heavy-Duty Gearing: The premier material for worm gears, spur gears, and gear rings that must transmit high torque and resist constant tooth wear, often as a sacrificial component protecting harder steel gears.

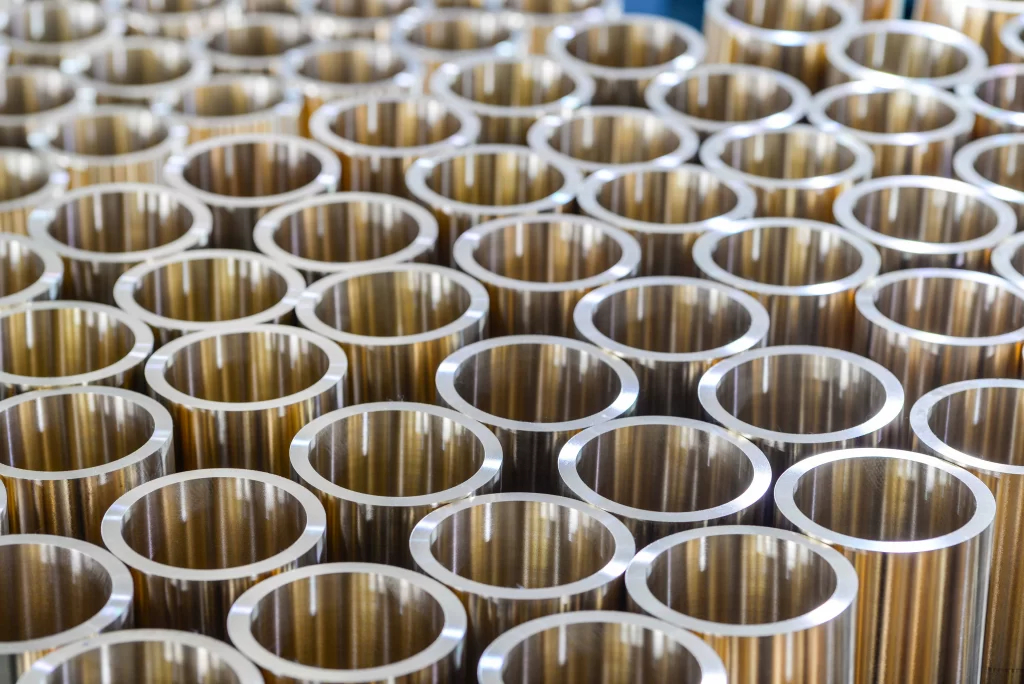

Industrial Bearings & Bushings: Ideal for high-load, low-speed bearings in steel mills, mining equipment, bridge turntables, and hydraulic systems where reliability is non-negotiable.

Marine & Offshore Engineering: From pump bodies and valve components to propeller bushings, its excellent seawater corrosion resistance ensures long-term reliability in the harshest environments.

General Machinery: A reliable choice for piston rings, steam fittings, impellers, and seal rings across countless industrial sectors.

6. Beyond the Alloy: The MYWAY Standard in Self-Lubricating Solutions

Understanding the material is only half the battle. The real-world performance of a bushing or bearing hinges on precision engineering, advanced composite design, and rigorous manufacturing. This is where MYWAY establishes its expertise.

While high-tin bronzes like CuSn12 provide a fantastic wear-resistant matrix, many modern applications demand built-in lubrication. MYWAY specializes in advanced self-lubricating composite bearings that take the core principles of bronze performance to the next level.

MYWAY’s DU/SF-1 Bushing: A Study in Layered Excellence

A prime example is the DU/SF-1 bushing, a multi-layer composite designed for optimal performance:

Steel Back (0.7-2.3mm): Provides exceptional mechanical strength, load-carrying capacity, and heat dissipation.

Copper Powder Sintered Layer (0.20-0.30mm): This porous bronze layer is the heart of the design. It ensures a perfect bond with the overlay and acts as a channel for superior heat conductivity.

PTFE/Lead Overlay (0.01-0.03mm): A mixture of modified PTFE and lead forms the active bearing surface. During operation, it creates a thin, slick transfer film on the mating shaft, providing a low coefficient of friction and protecting both surfaces from wear—even in dry or poorly lubricated starts.

This intelligent design encapsulates the evolution of tin bronze technology: leveraging bronze’s strength and thermal properties while solving the age-old problem of friction with an engineered polymer overlay.

7. Engineered for Your Challenge: The MYWAY Promise

Choosing MYWAY means more than buying a component; it’s partnering with a specialist dedicated to solving friction and wear problems.

Precision from the Ground Up: We employ tungsten steel precision molds and automated production lines to ensure that every bushing, from prototypes to large runs (10,000+ pieces for IDs under 50mm), meets exacting dimensional tolerances and surface finish standards.

Controlled Quality: Our materials are sintered in automatically controlled furnace systems, with strip thickness held to a tight ±0.01mm tolerance and verified by laser optical measurement.

From Blank to Finished Part: For gear manufacturers and machinery builders, we offer comprehensive services from supplying precision-machined bronze gear blanks to delivering ready-to-install, custom-finished bushings and bearings, helping you reduce scrap, save machine time, and control costs.

Ready to specify the right material and the right partner for your most demanding application?

Contact MYWAY today for a technical consultation and a quote. Let our engineering team help you select or develop the perfect tin bronze or self-lubricating composite solution to minimize downtime, extend service life, and reduce your total operating costs.

FAQ: Tin Bronze and Self-Lubricating Bearings

Q1: What’s the difference between “tin bronze” and “phosphor bronze”?

A: They are often used interchangeably. Technically, phosphor bronze is a type of tin bronze where phosphorus has been added as a deoxidizer during melting. The phosphorus (typically 0.01-0.45%) remains in the alloy, enhancing its wear resistance, hardness, and fatigue strength.

Q2: Why is tin bronze so good for marine environments?

A: Tin bronze exhibits exceptional corrosion resistance to seawater and brines. The alloy forms a stable, protective patina that prevents further degradation, making it ideal for ship propellers, pump parts, underwater fittings, and offshore platform components.

Q3: Can tin bronze bearings run without any lubrication?

A: Traditional monolithic tin bronze bearings generally require lubrication. However, modern composite bearings (like MYWAY’s MW-1 series) ingeniously combine a bronze structure with solid lubricants (e.g., PTFE, graphite). These create a self-lubricating transfer film, allowing them to operate for long periods with minimal or no external lubrication, perfect for maintenance-heavy or hard-to-reach applications.

Q4: Is high-tin bronze (like CuSn12) always the best choice for gears?

A: Often, yes. In bronze-to-steel gear pairs, the bronze gear is designed as the sacrificial component. High-tin bronzes like C90700 (SAE 65) offer the ideal balance: high strength to handle load, excellent wear resistance, and the ability to form a protective, low-friction tin-rich film on the mating steel gear, reducing overall system wear.

Q5: What are the main advantages of choosing a composite self-lubricating bushing over a traditional bronze bushing?

A: The key advantages are reduced maintenance (no need for frequent re-greasing), reliability in harsh conditions (dirty, dry, or extreme temperatures), clean operation (no grease contamination), and often higher load capacity due to the strong steel backing. They solve problems where traditional lubrication is impossible, unreliable, or undesirable.

100000+ Types of Bushings – Contact Us for Details