Recent Posts

Leaded Bronze Bushings: Enduring, Self-Lubricating Workhorse

In the demanding world of machinery, a critical component often works quietly in the shadows, ensuring smooth operation under immense pressure and stress: the leaded bronze bushing. For decades, this alloy has been the go-to choice for engineers facing high loads, low speeds, and challenging environments where lubrication is difficult. But what exactly makes this traditional material so enduringly valuable in modern applications? And how can you ensure you’re getting a bushing that meets today’s performance and reliability standards?

This guide will delve into the science and application of leaded bronze bushings, explaining why they remain indispensable and how advanced manufacturing, like that offered by MYWAY, can elevate their performance to solve your toughest engineering challenges.

Table of Contents

1. The Unmatched Legacy of Leaded Bronze

At its core, a leaded bronze is a copper-based alloy where lead particles are finely dispersed within a bronze (copper-tin) matrix. This seemingly simple combination creates a material with a unique set of properties:

Built-in Lubrication: The lead acts as a solid lubricant. During operation, it smears to form a protective film on the surface, significantly reducing friction and wear, especially in start-stop or boundary lubrication conditions. This self-lubricating quality is its most celebrated feature.

Superior Conformability and Embeddability: The soft lead phase allows the bushing to conform to minor misalignments in the shaft. More importantly, it can embed foreign particles like dust or grit that enter the system, preventing them from scoring the shaft—a vital trait in harsh environments like mining or agriculture.

Excellent Machinability and Dampening: Lead improves the alloy’s ability to be cut and shaped, reducing manufacturing costs. It also provides good vibration dampening.

Proven Performance Profile: Alloys like C93700 (High-Leaded Tin Bronze) are known for good corrosion resistance and reliable performance in a wide range of industrial and automotive equipment.

2. The Material in Action: Where Leaded Bronze Excels

Leaded bronze isn’t a one-size-fits-all solution, but it is the optimal solution for specific, demanding scenarios. According to material selection guides, leaded bronze is best suited for high-load, low-to-medium speed applications.

Here are some classic applications where its properties shine:

Heavy Industrial Machinery: Bushings in rolling mills, crushers, and large presses where shock loads and high surface pressures are common.

Marine and Offshore Equipment: Components like pump sleeves and rudder bearings benefit from its good corrosion resistance and ability to handle intermittent lubrication.

Agricultural Machinery: In environments rife with dirt and contamination, its embeddability protects critical drivetrains.

General Automotive and Industrial Applications: A workhorse material for a wide variety of bearings, bushings, and thrust washers in systems with moderate speeds and significant loads.

3. The Modern Evolution: Addressing Limitations with Advanced Technology

Traditional leaded bronze has its limits, including a relatively lower load capacity compared to some alternatives and environmental considerations regarding lead content. Modern engineering has developed advanced composite solutions that build upon the bronze foundation to overcome these hurdles.

The cutting edge is represented by bimetal or trimetal self-lubricating bushings. As detailed in a General Electric patent, a high-strength steel backing provides immense structural integrity and load capacity. On this, a porous sintered bronze layer is bonded. This layer is then impregnated with a polymer, typically PTFE (Teflon), creating a sophisticated, maintenance-free bearing surface.

This advanced design offers a powerful synergy:

Steel Backing: Bears the extreme load.

Bronze Interlayer: Provides thermal conductivity (dissipating heat) and a secure bond.

PTFE-Infused Surface: Delivers an extremely low, consistent coefficient of friction, superior corrosion resistance, and can operate completely dry or in media like water.

4. Why Partner with MYWAY for Your Bushing Solutions?

Choosing the right bushing is a technical decision, but choosing the right manufacturer is a strategic one. At MYWAY, we don’t just supply parts; we deliver engineered solutions that ensure reliability in your most critical applications.

Here’s how we add value to every leaded bronze bushing we produce:

Material Mastery and Selection Guidance: We understand the full spectrum of bronze alloys, from standard C93700/C93200 (SAE 660) for general use to specialized compositions. Our experts will guide you to the optimal material—be it traditional cast leaded bronze or a state-of-the-art steel-backed, PTFE-impregnated composite—for your specific load, speed, and environmental conditions.

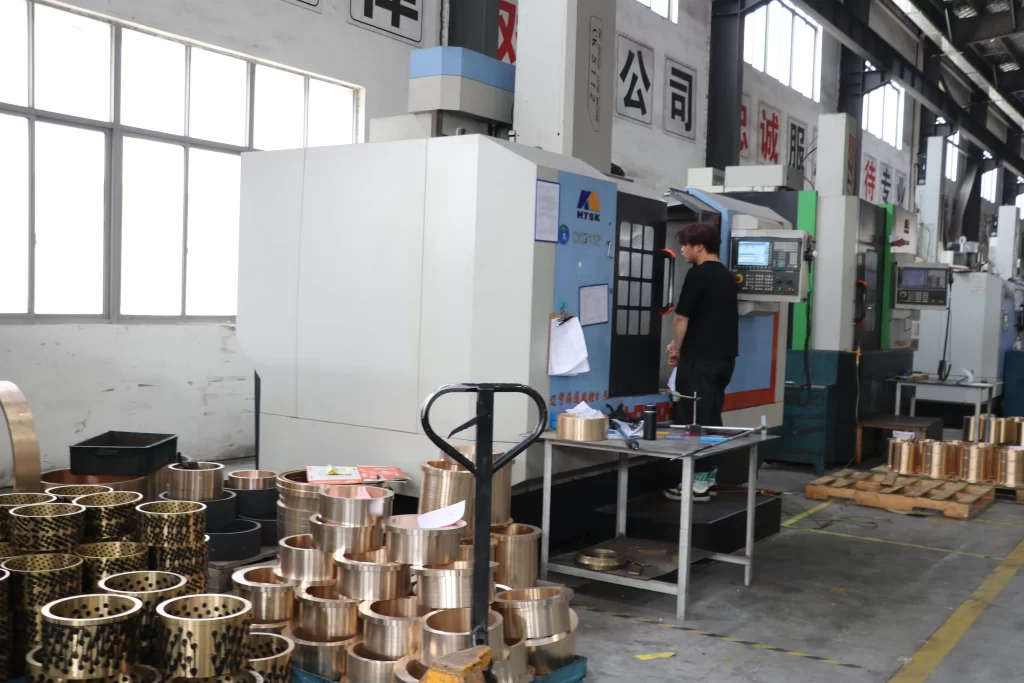

Precision Manufacturing for Reliability: Whether it’s precision casting of classic alloys or the sophisticated sintering and impregnation processes for advanced composites, our manufacturing rigor ensures every bushing meets exact dimensional and performance specifications. This translates to longer service life and fewer failures in the field.

Custom-Engineered for Your Application: We specialize in custom-sized bushings, including flanged designs for axial load management. Need a specific oil groove pattern, a unique wall thickness, or a special tolerance? Our engineering team can work with your design or develop one optimized for you.

A Partner Committed to Your Success: Our philosophy is built on “Quality as our lifeline.” We combine our deep manufacturing expertise—honed by supplying global leaders in construction and automotive—with a partnership approach to support your projects from prototype to high-volume production.

Ready to solve your high-load, low-speed bearing challenges with a reliable, high-performance solution?

Contact the MYWAY engineering team today. Let’s discuss your application, and explore how our expertise in leaded bronze and advanced self-lubricating bushing technology can enhance your machine’s durability and performance.

FAQ: Leaded Bronze Bushings

Q1: When should I choose a leaded bronze bushing over a polymer or plastic bushing?

A: Choose leaded bronze when your application involves high loads, low-to-medium speeds, and elevated temperatures. While polymers like Nylon or UHMWPE are excellent for lightweight, corrosive, or very low-friction needs, they can creep or deform under sustained high pressure. Leaded bronze maintains its structural integrity and performs reliably in these demanding conditions.

Q2: Are leaded bronze bushings truly “maintenance-free”?

A: Traditional cast leaded bronze bushings perform best with some lubrication, though their lead content provides a safety net during lubrication failure. However, modern PTFE-impregnated, steel-backed bronze bushings are designed to be truly maintenance-free and can operate dry for their entire service life, making them ideal for sealed or hard-to-service locations.

Q3: What’s the difference between a standard sleeve bushing and a flanged bushing?

A: A standard sleeve bushing primarily handles radial loads (forces perpendicular to the shaft). A flanged bushing includes a collar or lip that allows it to also withstand significant axial (thrust) loads (forces parallel to the shaft), providing positioning and load support in two directions.

Q4: Can MYWAY produce bushings for both replacement (aftermarket) and new equipment (OEM) design?

A: Absolutely. We excel in both. For the aftermarket, we provide high-quality, direct-replacement bushings that restore or even improve upon original performance. For OEMs, our engineering team collaborates on design-for-manufacturability, offering custom material specifications and geometries to optimize performance and cost in new machinery.

Q5: My application is in a wet or corrosive environment. Is leaded bronze suitable?

A: Leaded bronzes offer good general corrosion resistance. For highly corrosive environments like seawater, specific alloys or surface treatments can be used. In many cases, an advanced steel-backed bushing with a PTFE-composite surface is an excellent choice, as PTFE is highly inert and resistant to most chemicals, while the steel backing is protected from the medium.

100000+ Types of Bushings – Contact Us for Details