Recent Posts

Sintered Bronze Bushings: The Classic Workhorse and When to Upgrade for Demanding Performance

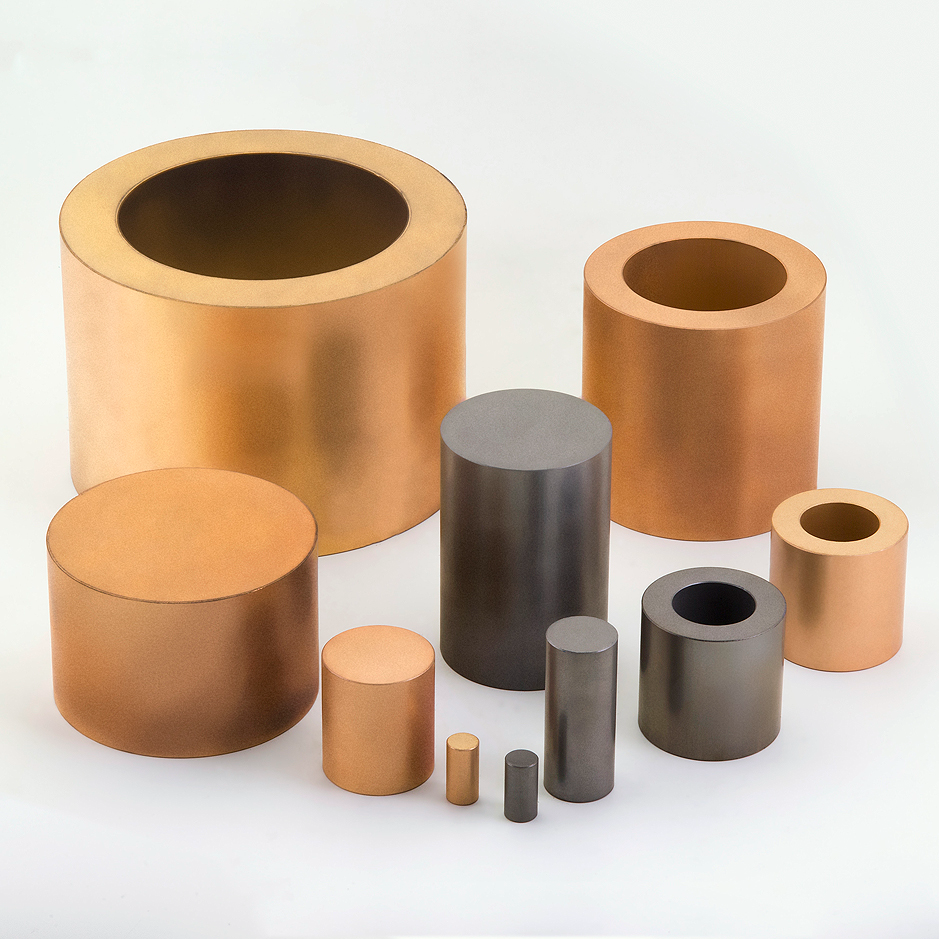

For decades, sintered bronze bushings have been the dependable, go-to solution for countless rotary and sliding applications. Found in everything from power tools and small appliance motors to automotive starters and conveyor rollers, their reputation for being self-lubricating and maintenance-free is well-earned. But how do they actually work, and are they always the best choice for today’s more demanding industrial applications?

This article explores the science, strengths, and limitations of traditional sintered bronze bushings. More importantly, we’ll discuss scenarios where advanced engineered composites, like those offered by MYWAY, provide a superior solution for reliability, longevity, and performance in challenging conditions.

Table of Contents

1. How Sintered Bronze Bushings Earn Their Reputation: Porosity is Key

The magic word is sintering. This manufacturing process involves compacting fine bronze powder (typically a copper-tin alloy) into a shape under high pressure and then heating it below its melting point. This creates a solid metal component with a unique, uniformly porous structure—typically 15-25% of its volume consists of microscopic interconnected pores.

This porous matrix is then impregnated with lubricating oil. During operation, frictional heat causes the oil to expand and migrate from these pores to the bearing’s sliding surface. As the shaft rotates, it draws this oil to form a thin hydrodynamic film, separating the surfaces and reducing friction. When operation stops, the oil cools and is partially reabsorbed via capillary action. This ingenious “self-oiling” mechanism is why they are celebrated as a maintenance-free bearing solution for many applications.

2. Ideal Applications: Where the Classic Bushing Shines

Sintered bronze bushings excel in stable, continuous-operation environments with specific parameters. They are ideally suited for:

Continuous or high-speed rotation: The hydrodynamic film builds and maintains best under consistent motion.

Light to moderate loads: Typical dynamic load ratings are around 10 N/mm².

Benign environments: They perform well in clean, dry conditions away from aggressive chemicals or excessive contamination.

Cost-sensitive, high-volume applications: Their powder metallurgy manufacturing makes them very economical for standardized parts.

You’ll reliably find them in electric motors, office machinery, household appliances, and packaging equipment—applications where they run predictably within their design limits.

3. Recognizing the Limits: When the Classic Design Reaches Its Threshold

Despite their advantages, traditional oil-impregnated bronze bushings have inherent limitations rooted in their design:

Limited Oil Reservoir: The oil volume is finite. In high-temperature operations (typically above 80-90°C), oil can oxidize, evaporate, or leak out, depleting the reservoir and leading to dry running and rapid failure.

Sensitivity to Intermittent Use: Slow, oscillating, or frequently start-stop motion may not generate enough frictional heat to effectively pump oil to the surface, leading to boundary lubrication and increased wear.

Low Tolerance for Contamination: While the porous surface can embed some particles, heavy contamination can clog pores, blocking oil release and acting as an abrasive.

Moderate Load & PV Capacity: Their strength is limited by the sintered bronze material. High shock loads, heavy static loads, or combined high pressure and speed (a high PV value) can overwhelm the structure.

Dimensional Limitations for Customization: While standard sizes are plentiful, creating complex custom geometries or very large diameters with consistent porosity can be challenging and costly with traditional sintering.

When an application involves variable loads, high temperatures, frequent starts and stops, exposure to dirt or chemicals, or requires a custom design, the sintered bronze bushing’s weaknesses can become critical failure points.

4. The Engineered Upgrade: Advanced Composite Bushings by MYWAY

For applications pushing beyond the limits of standard sintered bronze, modern composite bushings offer a robust, next-generation solution. At MYWAY, we engineer bushings that address the very challenges where traditional designs falter.

Consider our steel-backed, PTFE composite bushings (such as the DU/SF-1 series). This is not a porous metal but a sophisticated multi-layered, self-lubricating system:

| Layer | Material | Function & Advantage over Sintered Bronze |

|---|---|---|

| Backing Layer | High-Strength Steel | Provides immense structural integrity and load capacity (static loads up to 250 N/mm²), allows for secure press-fit in demanding housings. |

| Intermediate Layer | Sintered Bronze Matrix | Provides a bonded, porous foundation for the top layer and offers excellent thermal conductivity to dissipate heat. |

| Sliding Surface | PTFE (Polytetrafluoroethylene)-Based Composite | This is the game-changer. It provides an inherently low-friction, maintenance-free surface that performs reliably from the first movement, independent of speed or heat to release oil. It is chemically inert and excels in dry or lubricated conditions. |

This engineered approach delivers performance where traditional bushings struggle:

True Dry-Running Capability: No oil reservoir to deplete. Perfect for applications where lubrication is impossible or undesirable.

Excellent Performance Under Intermittent Motion: The ready-to-slide PTFE surface ensures low friction from the start, ideal for oscillating movements or slow speeds.

High Load & Shock Resistance: The steel backing supports significantly higher loads and impact forces.

Wider Temperature Range: PTFE composites can operate from -200°C to +280°C, far exceeding the thermal limits of oil.

Superior Contamination Tolerance: The soft PTFE layer can safely embed foreign particles, protecting the shaft.

5. The MYWAY Advantage: From Material Science to Reliable Delivery

At MYWAY, we bridge the gap between advanced material science and real-world industrial reliability. We understand that choosing a bushing is a critical engineering decision impacting machine uptime and total cost of ownership.

Why partner with MYWAY for your bushing needs, whether standard or advanced?

Solution-Oriented Expertise: We don’t just sell parts; we provide bearing solutions. Our engineers can help you analyze your application—considering load, speed, temperature, and environment—to recommend the optimal material, whether it’s a cost-effective sintered bronze bushing for a standard application or a high-performance PTFE-steel composite for a demanding one.

Full-Spectrum Manufacturing Prowess: Our vertical integration is key. We control the entire process, from powder metallurgy for sintered components to the precise sintering and rolling of advanced composites. With an annual casting/sintering capacity of thousands of tons, we ensure scalability, consistency, and quality control for every unit that leaves our factory.

Proven Track Record with Global Brands: Our components are trusted in critical applications by over 300 major companies, including leaders in construction (XCMG, SANY) and automotive (Great Wall Motors). This experience means we understand the rigor required for industrial-grade components.

Customization and Engineering Support: Need a non-standard size, a specific flange design, or a material tweaked for unique conditions? Our engineering team collaborates with you to develop and prototype custom bushing solutions that fit your design perfectly, not just your catalog.

Facing a bushing challenge where standard solutions are falling short?

Contact the MYWAY engineering team today. Let’s discuss how our expertise in both sintered bronze and advanced self-lubricating composite bushings can provide a more reliable, durable, and cost-effective solution for your application.

6. FAQ: Sintered Bronze and Advanced Bushing Solutions

Q1: When should I definitely choose a traditional sintered bronze bushing?

A: Choose sintered bronze for cost-sensitive, high-volume applications with stable, continuous rotation at light to moderate loads in clean, moderate-temperature environments. They are a superb, economical default for motors, appliances, and similar machinery where operating conditions are predictable and within standard limits.

Q2: The oil in my sintered bushings keeps drying out. What’s a better option?

A: This indicates your application likely involves high temperatures, intermittent use, or excessive side load that squeezes out the oil. An upgrade to a steel-backed, PTFE composite bushing from MYWAY is ideal. Its solid lubricant layer does not dry out or migrate, providing consistent performance regardless of thermal cycles or operational pauses.

Q3: Can MYWAY supply both sintered bronze and the more advanced composite bushings?

A: Absolutely. We are a full-service manufacturer. We produce high-quality, oil-impregnated sintered bronze bushings in standard and custom metric/imperial sizes for general applications. Simultaneously, we engineer and manufacture advanced self-lubricating composite bushings (like DU/SF-1) for demanding scenarios. We provide unbiased advice on the most cost-effective and reliable solution for your specific case.

Q4: We have a high-load, low-speed oscillating application. Sintered bronze failed quickly. Why?

A: This is a classic failure mode. Sintered bronze relies on shaft speed to generate an oil film. In low-speed, high-load oscillating applications, the film cannot form effectively, leading to metal-to-metal contact and rapid wear. A PTFE-based composite bushing operates effectively at any speed, making it the perfect choice for slow, heavy oscillating movements like those in construction or agricultural equipment linkages.

Q5: Do you offer custom sizes and shapes for sintered components?

A: Yes. While powder metallurgy (sintering) has some geometric constraints compared to machining, we specialize in producing custom sintered bronze components beyond simple cylinders. This includes flanged bushes, specific wall thicknesses, and certain non-round profiles. For highly complex geometries, we may recommend starting with a sintered pre-form and finishing with precision machining, or evaluating if a composite solution is more suitable.

100000+ Types of Bushings – Contact Us for Details