Home » Bushing VS Bearing » Which is Better: Bearing vs. Bushing?

Which is Better: Bearing vs. Bushing?

When choosing between bearings and bushings, it’s essential to consider your application’s unique requirements. Both components play a vital role in reducing friction and supporting motion, but they differ in structure, performance, and ideal use cases.

Which is better—bearing or bushing? The answer lies in your application needs:

Bushings: Best for low-speed, heavy-load, or cost-sensitive applications with minimal maintenance requirements.

Bearings: Ideal for high-speed, precision, and dynamic load scenarios where efficiency and accuracy are critical.

In this article, we’ll answer common questions buyers often search for when deciding between bearings and bushings, helping you make an informed decision.

Table of Contents

1. What Are the Differences between a Bearing and a Bushing?

To figure out which is better, you first need to understand the fundamental differences between bushings and bearings:

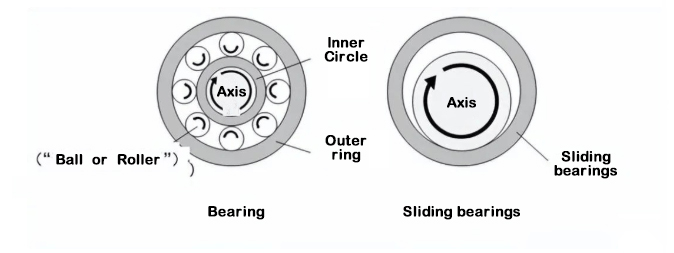

1.1 Bearing

Bearings usually have rolling elements (think balls or rollers) designed to reduce friction and support movement. Bearings are ideal for high-speed and dynamic applications.

Bushings typically mount between two surfaces using sliding friction to reduce wear between them. They work well for things that grind against each other. Bushings excel in low-speed, heavy-load, or cost-sensitive applications.

In short, remember that bushings have things slide, and bearings have things roll when it comes to which one you need to use. This difference directly impacts their performance and suitability for various industrial needs.

2. What Are the Advantages of Bushings Over Bearings?

Bushings offer several benefits that make them the better choice for certain scenarios:

- Cost-Effectiveness:

Bushings are simpler and cheaper to manufacture, making them a budget-friendly option for buyers who need high quantities. - Low Maintenance Requirements:

Many bushings are made from self-lubricating materials (e.g., bronze, polymer, or composite), reducing the need for regular maintenance. - Heavy-Load Capacity:

The larger contact area of bushings allows them to handle static loads and shock loads better than bearings. This is particularly useful in industries like construction equipment, agriculture machinery, and automotive suspensions. - Durability in Harsh Conditions:

Bushings perform well in environments with dirt, debris, or corrosion. Unlike bearings, they don’t have rolling elements that can seize or fail under harsh conditions. - Compact Design:

With a simple tubular structure, bushings require less space and are easier to install, making them a practical solution for tight-fitting assemblies.

3. What Are the Advantages of Bearings Over Bushings?

On the other hand, bearings excel in areas where bushings fall short:

- High-Speed Performance:

Bearings are designed for dynamic and high-speed applications. The rolling elements significantly reduce friction, allowing for smoother and more efficient motion in machinery like electric motors, industrial fans, and robotics. - Precision and Accuracy:

Bearings are highly precise, making them essential in industries like aerospace, medical devices, and manufacturing, where tight tolerances are required. - Energy Efficiency:

The lower rolling resistance in bearings helps reduce energy loss, ensuring smoother operation and less wear on machinery components. - Dynamic Load Handling:

Bearings are better suited for applications with changing or fluctuating loads, such as rotating machinery, conveyor systems, and vehicle wheels. - Longer Lifespan in High-Performance Scenarios:

With proper lubrication and maintenance, bearings can outperform bushings in high-speed, continuous-use applications.

4. Which Is Better for Heavy-Load Applications? Bearings VS Bushings

In the B2B world, especially for those of us who like to make things or source these types of pieces to make things, bushings are generally more cost-effective:

-They’re simpler to make.

–reduce ongoing maintenance expenses.

However, bearings, while more expensive, can provide better long-term value in high-speed or precision applications due to their efficiency and durability. The choice comes down to balancing initial cost with performance requirements.

5. Do Bearings or Bushings Require More Maintenance?

At the same time, bearings usually require more maintenance work. This maintenance includes proper lubrication, inspection to ensure the rollers and the seals don’t get torn up, don’t get overrun, and don’t break deal. If bearings don’t get cared for properly, they’re going to scream and die!

6. Can Bearings Replace Bushings in Machinery?

7. Which Is Better for Your Industry?

8. Conclusion

100000+ Types of Bushings – Contact Us for Details