MYWAY Bushing: Automotive Braking System Bushing Solutions

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Automotive » Automotive Braking System Bushing

MYWAY Automotive Braking System Bushing

Auto Bus Brake Pedal Bushing

Model Number: 35V47-01516 Package Dimensions: 16x40x33cm Package Weight: 150 products total 14.6kg Material: Steel

Automotive Brake Shoe Bushing

Automotive Brake Shoe Bushing

BRAKE SHOE BUSHING MERCEDES- 3354210250

Brake Shoe Bushing 667962, d: 22 mm

for OE number 667962 Height [mm] 27 mm Type Brake shoe bushing Inner Diameter [mm] 22 mm Outer diameter 25 mm Net Weight [g] 23 g OE/OEM Part Number DAF 0667962, DAF 667962

Automotive Braking System Bushing

Automotive Braking System Bushing

Automotive Braking System Bushing

Height [mm] 73 mm Type Bushing Inner Diameter [mm] 42 mm Outer diameter 46 mm Net Weight [g] 132 g

Automotive Braking System Bushing

Automotive Braking System Bushing

Automotive Braking System Bushing

Automotive Braking System Bushing

Weight: 0.18 lbs

500+ Types of Automotive Braking System Bushings – Contact Us for Details

| Component Category | Specific Type / Model |

| Automotive Braking System Bushing | Wrapped Copper Bushings |

| Self-lubricating Bushings | |

| Bimetal Bushings |

How Premium Automotive Braking System Bushings Elevate Performance and Safety

Introduction

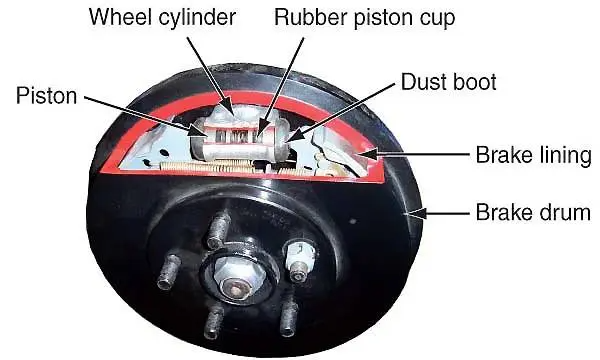

When you think about your car’s brakes, you likely picture discs, pads, and calipers. But nestled within the brake caliper assembly and other critical junctions is a small, yet vital component working silently: the braking system bushing. These unassuming parts are pivotal for precise alignment, smooth operation, and effective vibration damping. As the global automotive brake systems market evolves with new technologies, and regulations like China’s 2025 brake system standards place greater emphasis on reliability and functional safety, the quality of every component, including bushings, has never been more critical. This article explores why these small parts matter and how choosing the right supplier can make a significant difference.

What Are Braking System Bushings and Why Do They Matter?

Automotive braking system bushings are sleeves or liners, often made from metals, polymers, or composites, used at connection and pivot points. In a brake caliper, for instance, bushings allow the caliper to slide smoothly on its pins or bolts, ensuring the pads clamp the brake disc evenly.

Their core functions are:

Precision Alignment: They maintain the exact position of moving parts like calipers, which is essential for even pad wear and consistent braking performance.

Vibration Damping and Noise Reduction: By absorbing shocks and oscillations, they prevent brake squeal and provide a quieter, more comfortable ride.

Friction Management: They facilitate smooth movement with minimal resistance, which is crucial for the proper function of sliding components.

The push for protoless development and virtual validation in the industry makes accurately simulating bushing behavior in systems like the brake pedal assembly key to predicting real-world performance.

The High Cost of Compromise: Risks of Substandard Bushings

Choosing bushings based on price alone can lead to significant downstream issues:

Premature and Uneven Wear: Poor alignment from low-quality bushings causes brake pads and discs to wear out faster and irregularly, increasing maintenance costs.

Noise, Vibration, and Harshness (NVH): Inadequate damping results in noticeable brake squeal, shuddering, or a spongy pedal feel, degrading driver experience.

Compromised Safety and Performance: In extreme cases, excessive play or seizure in caliper slide pins due to bushing failure can lead to reduced braking efficiency or even partial brake failure.

Increased Total Cost of Ownership: Frequent replacements, additional part wear, and potential vehicle downtime far outweigh the initial savings from a cheaper component.

The MYWAY Advantage: Engineering Excellence in Every Bushing

At MYWAY, we understand that a bushing is not just a commodity but a precision-engineered component. Our Automotive Braking System Bushings are designed to meet the rigorous demands of modern vehicles, from passenger cars to commercial vehicles.

Our Specialized Product Line:

We offer a comprehensive range of solutions tailored for braking applications:

MYWAY Caliper Pin Bushings: Manufactured from self-lubricating bronze or advanced polymers for smooth, consistent sliding motion, preventing stick-slip and ensuring reliable caliper operation.

Brake Pedal Pivot Bushings: Engineered to provide the precise stiffness and damping characteristics required for optimal pedal feel and accurate simulation in finite element analysis (FEA).

Custom-Designed Bushing Solutions: We collaborate with clients to develop bushings for specialized applications, including emerging electro-mechanical brake (EMB) systems.

Why Choose MYWAY Bushings?

| Feature | Benefit for Your Braking System |

|---|---|

| Premium Materials | Use of graphite-impregnated bronze, high-performance polymers, and PTFE composites for exceptional wear resistance, self-lubrication, and longevity. |

| Precision Manufacturing | Tight tolerances and consistent quality ensure perfect fit and function, guaranteeing reliable braking performance and alignment. |

| Thermal & Chemical Resistance | Formulations designed to withstand high temperatures from braking and resist corrosion from road salts and brake fluid. |

| Expert Technical Support | Our engineering team provides support from material selection and design optimization to integration guidance. |

Navigating a Changing Market with a Trusted Partner

The automotive braking industry is in flux. The shift towards electric vehicles (EVs) and hybrids demands components that manage new NVH challenges and integrate with regenerative braking systems. Simultaneously, stringent new standards, such as China’s 2025 update which mandates higher functional safety (ASIL) levels, require components from a certified, technically proficient supply chain.

MYWAY is positioned as your ideal partner in this landscape. We don’t just sell parts; we provide engineered solutions that enhance your system’s reliability, safety, and performance. By investing in high-quality MYWAY bushings, you invest in reduced warranty claims, stronger brand reputation for quality, and ultimately, greater customer satisfaction.

Frequently Asked Questions (FAQs)

Q1: How often should brake caliper bushings be inspected or replaced?

A: There’s no universal mileage, but they should be checked whenever brake pads are replaced. Signs of wear include uneven pad wear, brake dragging, squealing, or a stuck caliper. High-quality bushings like ours offer dramatically extended service life.

Q2: Can MYWAY produce bushings according to our specific drawings and material specifications?

A: Absolutely. Customization is a cornerstone of our service. We can manufacture bushings to your exact CAD drawings, using a wide range of materials including specialized bronze alloys, copper-alloy, and polymers to meet your application’s load, environmental, and performance needs.

Q3: Are your bushings suitable for electric vehicles?

A: Yes. Our materials are engineered to perform under the unique conditions of EVs, such as different vibration frequencies and the need for exceptional durability in corrosion-resistant applications.

Q4: What certifications does MYWAY hold?

A: We operate a certified quality management system. Please contact our team for the most current details on our certifications and compliance with international automotive standards.

Q5: How can I request a quote or technical datasheet?

A: Visit our website’s contact page or email us directly. Please provide your component drawings, material preferences, and annual volume requirements for a prompt and detailed quotation.