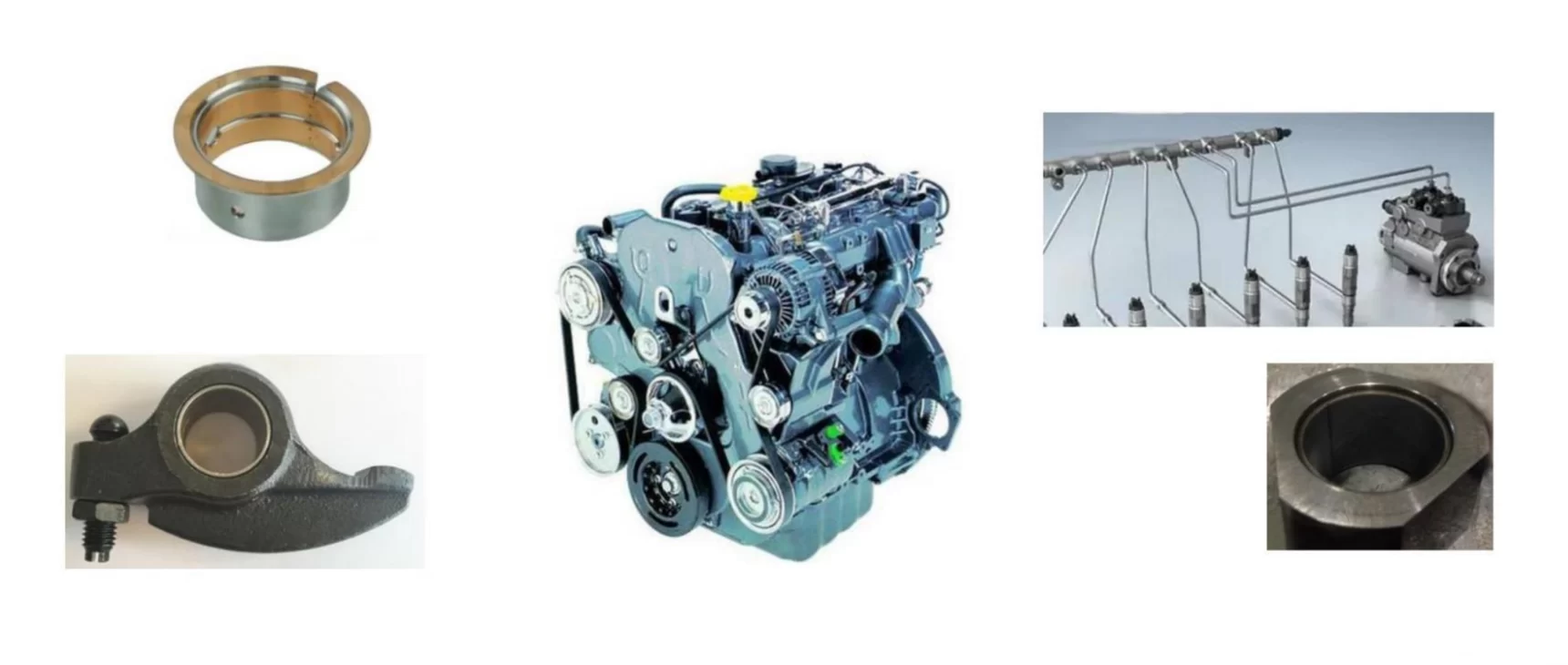

MYWAY Automotive engine Camshaft bushing & Valve Rocker Arm bushing & High-Pressure Common Rail System bushing

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Automotive » Automotive Engine Camshaft Bushing & Valve Rocker Arm Bushing & High-Pressure Common Rail System Bushing

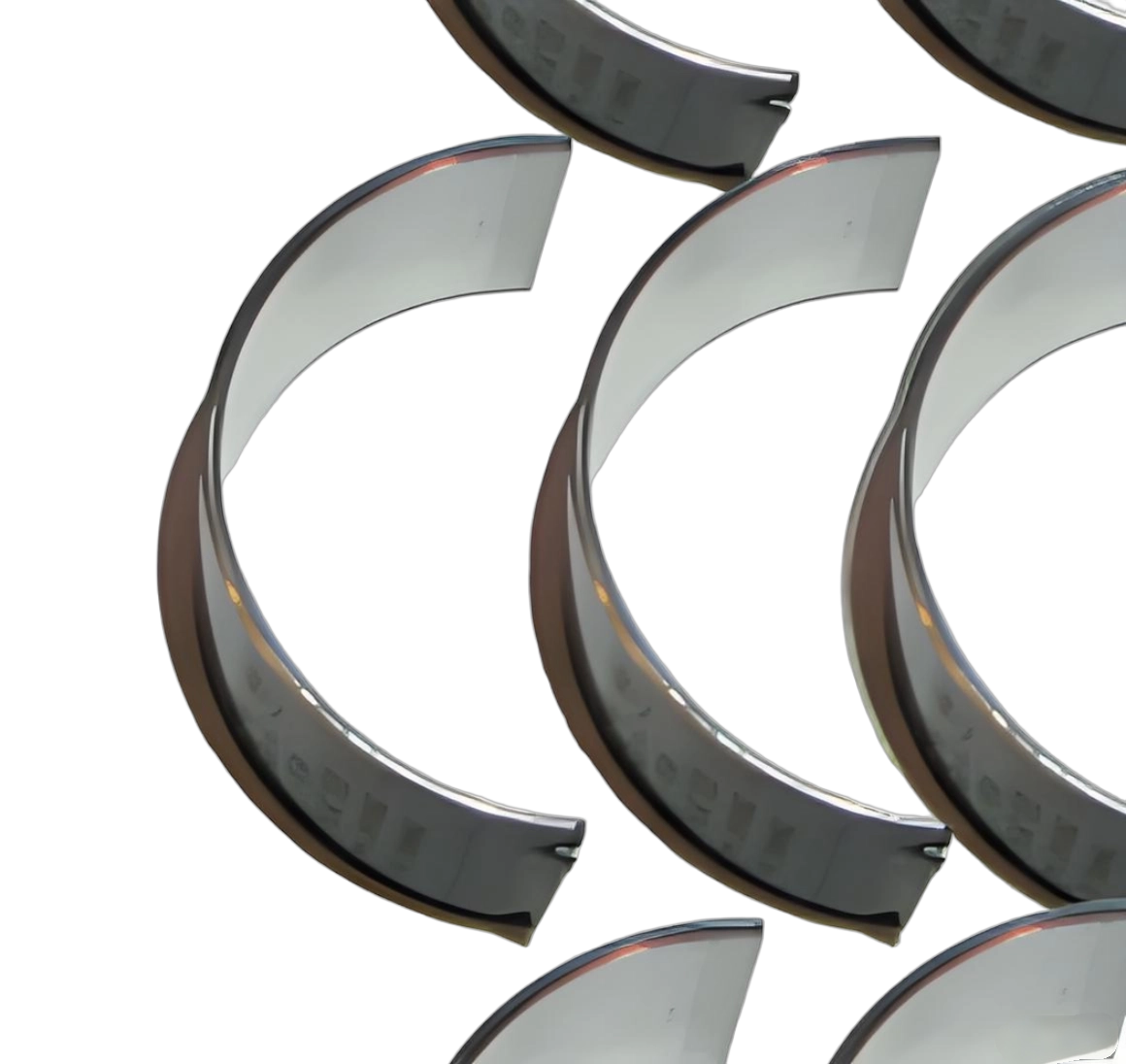

MYWAY Automotive engine Camshaft bushing

Camshaft Bushing 3901685 3943199 for Cummins Engine 6CT8.3 6CTA8.3 6CTAA8.3 QSC8.3 QSL9 S6D114 S6D114-1

Product description Camshaft Bushing 3901685 3943199 Compatible with Cummins Engine 6CT8.3 6CTA8.3 6CTAA8.3 QSC8.3 QSL9 S6D114 S6D114-1 Part Number: 3945329 3901685 3943199 Application: Compatible with Cummins Engine 6CT8.3 6CTA8.3 6CTAA8.3 QSC8.3 QSL9 S6D114 S6D114-1 SA6D114-1 SA6D114-1AA SA6D114E-1-GD SAA6D114E-2 SAA6D114E-2A-A SAA6D114E-3 SAA6D114E-5

Engine Camshaft Bushing Compatible With Chevrolet Express 3500 2007 2006 2005 2004 2003 1996 P-1927560

Camshaft Bushing 3002834 for Cummins Engine KTA19 QSK19 B3.3 K19 N14 QSK38 QSNT14

Camshaft Bushing 3002834 for Cummins Engine KTA19 QSK19 B3.3 K19 N14 QSK38 QSNT14 Replacement Part Number: 76103789, 3002834 Fit For Cummins Engine: B3.3, ISC CM850, K19, KTA19 G CMEICS K123, KTA19E G CMEICS K151G, KTA19GC, KTA19GC CM558, KTAA19 K131G, N14 MECHANICAL, QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, QSK38 CM850 MCRS, QSNT14 CM876 N103

3820566 Camshaft Bushing Compatible with Engine L10 M11 QSM11

3820566 Camshaft Bushing Compatible with Engine L10 M11 QSM11

Cummins Gta855 Parts Manual Cummins Camshaft Bushing - OEM Replacement For Dodge 3.9L/5.9L/6.7L (Part #3940059) 5633435 Cummins

Cummins 3940059 Camshaft Bushing (Thick) – OEM for 5.9L/6.7L ISB (1997.5–2018)

1997.5–2002 5.9L 24-Valve ISB Cummins 2003–2007 5.9L Common Rail ISB Cummins 2007.5–2018 6.7L ISB Cummins (Dodge/Ram & medium-duty platforms) Industrial, agricultural, and construction B-Series / ISB engines (verify by ESN) Important: Cam bushings vary by ESN and block machining requirements. Always verify your engine serial number (ESN) before ordering.

Eastern Motorcycle Parts Camshaft Bushing - A-25344-99 for Select Harley-Davidson Motorcycles

Specifications Mfg #: A-25344-99 Part #: 1400044 Style Plain Type Camshaft Bushing Units Each Weight 0.05 lbs Vendor Part Number(s): 09210528

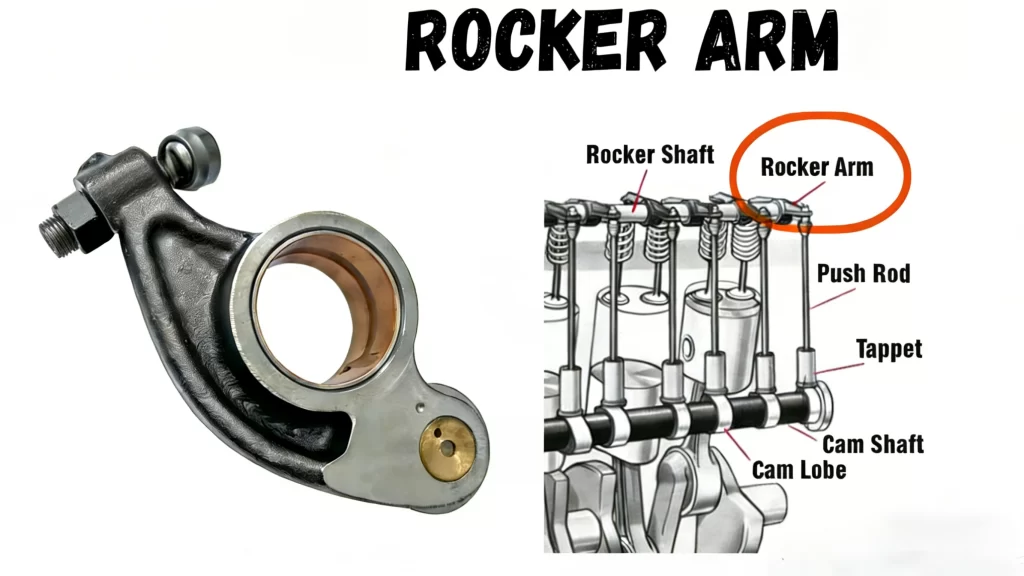

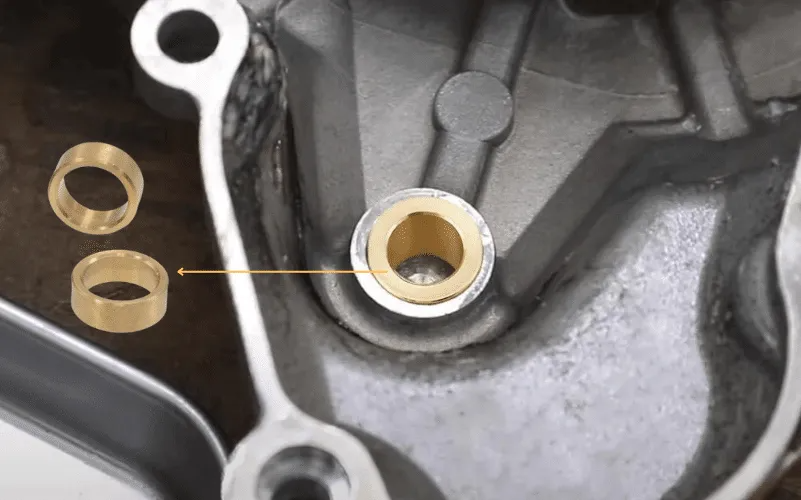

MYWAY Automotive Valve Rocker Arm bushing

Me302279 Bushing Used in Valve Rocker Arm for Mitsubishi 6m60

Model NO. 6M60 Technics Forging Material Iron Type Engine Part Machine Model Katoo HD1638-R5 Engine Model 6m60 Stock Status Available Part Name Bushing Transport Package Normal Packing

Rocker Arm Valve Bushings 1346 Solid Type 22 Vintage Chevrolet 1934-1940 P3

O.D Size 7/8" I.D. Size 25/32" SKU P3 Finish Brass Placement on Vehicle Left, Right, Front Car & Truck Parts & Accessories Engines & Engine Parts

Porsche Rocker Arm Shaft Bushing - OE Supplier 90110534403

Details SKU: OEM-90110534403 FCP Euro ID: 508017 Quality: OEM OE Numbers 90110534403, 90110534402, 90110534401

Kibblewhite 20-2106 Bronze Alloy Rocker Arm Bushings Kibblewhite Precision Rocker Arm Bushings 20-2106 - Bronze Alloy Engine Parts Valve Train Par

Rocker Arm Bush For Cummins Engines in Secunderabad

Diesel Series 60 Rocker Arm Assembly Bushing A8929059

1997.5–2002 5.9L 24-Valve ISB Cummins 2003–2007 5.9L Common Rail ISB Cummins 2007.5–2018 6.7L ISB Cummins (Dodge/Ram & medium-duty platforms) Industrial, agricultural, and construction B-Series / ISB engines (verify by ESN) Important: Cam bushings vary by ESN and block machining requirements. Always verify your engine serial number (ESN) before ordering.

24122 Bushing, Rocker Arm

Categories: Continental A65, A75 & A80, Continental C125, C145 & O-300, Continental C75 & C85, Continental C90 & O-200, Continental GO-300

MYWAY Automotive High-Pressure Common Rail System bushing

F 01M 101 211 BOSCH Control Valve, fuel quantity (common rail system) High Pressure Pump (low pressure side)

Fitting Position: High Pressure Pump (low pressure side) Item number: F 01M 101 211

Automotive High-Pressure Common Rail System bushing

5000+ Types of Automotive engine Camshaft & Valve Rocker Arm & High-Pressure Common Rail System bushings – Contact Us for Details

| Component Category | Specific Type / Model | Product Series Name |

|---|---|---|

| Engine Components | Automotive Engine Camshaft Bushing | Bimetal / Steel Sleeve |

| Engine Components | Valve Rocker Arm | Bimetal / Steel Sleeve |

| Fuel System Components | High-Pressure Common Rail System | Bimetal / Steel Sleeve |

A Deep Dive into Critical Engine Bushings for Camshafts, Rocker Arms & Common Rail Systems

Introduction: Why the Smallest Parts Matter Most

In the world of automotive and diesel engine engineering, massive horsepower figures and cutting-edge turbochargers often steal the spotlight. However, seasoned engineers and master technicians know a fundamental truth: an engine’s ultimate reliability, efficiency, and longevity are frequently determined by its smallest, most unassuming components. Among these, precision bushings and sleeves play a critical, albeit understated, role.

This article focuses on three high-stress, high-precision application areas where bushing failure is not an option: the camshaft, the valve rocker arm assembly, and the ultra-high-pressure common rail fuel system. We will explore their function, common failure modes, material science, and why selecting the correct busings—like those from MYWAY— is a strategic decision for performance and durability.

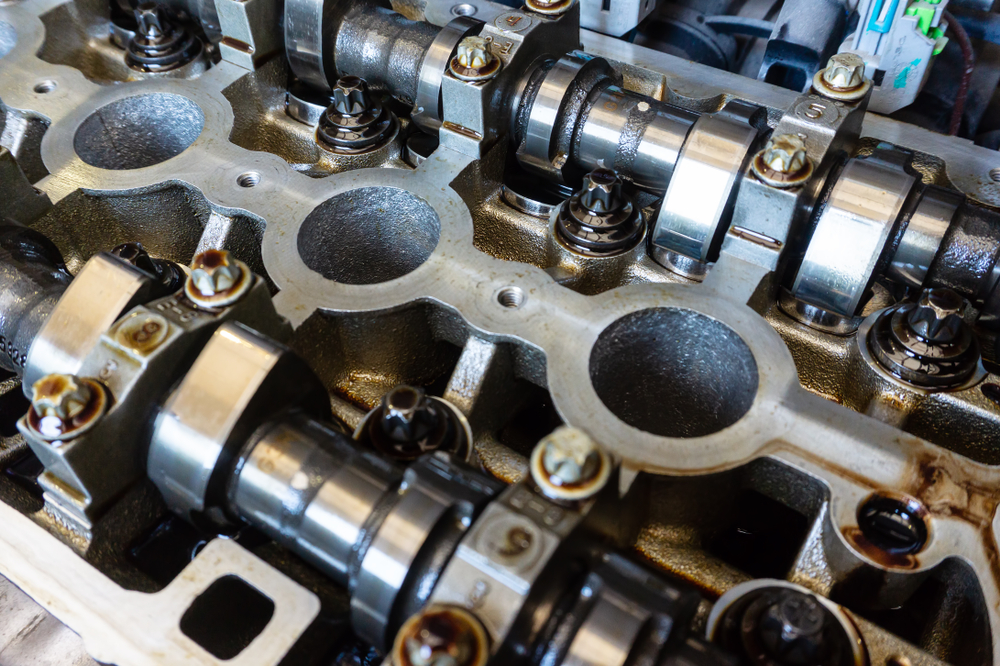

Part 1: The Automotive Engine Camshaft Bushing – The Conductor’s Pivot

Function & Importance:

The camshaft is the maestro of the combustion orchestra, precisely timing the opening and closing of intake and exhaust valves. Camshaft bushings (or bearings) are the pivot points on which this maestro rotates. They are pressed into the cylinder head or engine block, supporting the camshaft journals and maintaining critical oil clearance.

Failure Modes & Consequences:

Wear & Increased Clearance: Leads to low oil pressure, excessive camshaft movement, inaccurate valve timing, and ultimately, reduced engine power and efficiency.

Scoring & Seizure: Often caused by oil starvation or contamination. Can result in catastrophic engine failure, shearing the camshaft or destroying the cylinder head.

Fatigue & Spalling: Common in high-performance or heavily loaded engines, where the bearing material fatigues and flakes off.

Material & Technology Solution:

For camshaft applications, bimetal bushings are the industry standard for a reason. A MYWAY bimetal bushing typically features:

A High-Strength Steel Back: Provides structural integrity and perfect press-fit into the housing.

A Precision-Bonded Inner Layer: Often a copper-based alloy (e.g., leaded bronze) or aluminum-tin alloy, offering excellent embeddability for contaminants, conformability to slight misalignments, and superior wear resistance.

Optimized Grooving & Oil Hole Geometry: Ensures consistent lubricant film formation across the entire journal surface.

Part 2: The Valve Rocker Arm Bushing – The Fulcrum of Force

Function & Importance:

The valve rocker arm translates the rotational motion of the camshaft lobe into the vertical force needed to open the valve. The rocker arm bushing is the fulcrum at the heart of this lever. It houses the rocker shaft and must withstand intense, repetitive impact loads and sliding friction.

Failure Modes & Consequences:

Ovalization & Wall Fatigue: The hammering effect from valve springs can deform the bushing, increasing clearance and causing valvetrain noise (ticking), lost valve lift, and poor engine compression.

Gallling & Adhesive Wear: Occurs under boundary lubrication conditions, leading to metal-to-metal contact and eventual seizure of the rocker arm on the shaft.

Material & Technology Solution:

Rocker arm bushings demand a material that balances shock load absorption with wear resistance. MYWAY Steel Sleeves or advanced bimetal designs excel here due to:

Case-Hardened or Through-Hardened Steel: Provides a tremendously hard, durable wearing surface that resists ovalization.

Precision ID Finishing: A mirror-smooth internal diameter (ID) surface finish minimizes friction and promotes oil film retention.

Consistent Wall Thickness & Density: Guarantees uniform load distribution and prevents premature fatigue failure.

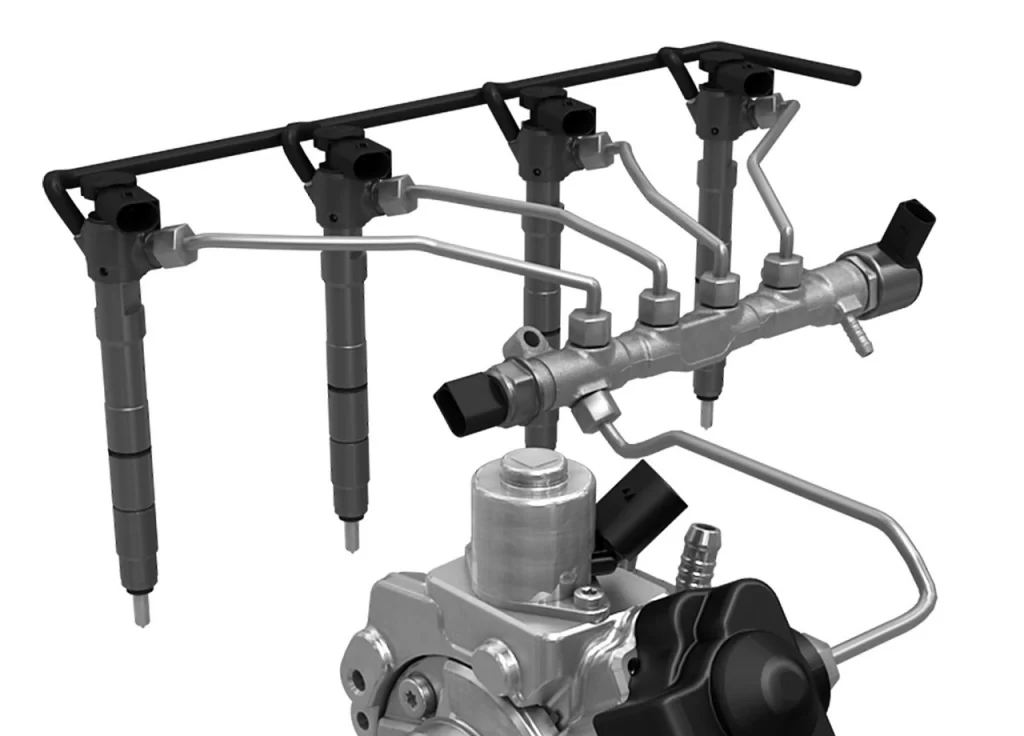

Part 3: High-Pressure Common Rail (HPCR) System Bushings & Sleeves – Containing the Fury

Function & Importance:

Modern diesel engines rely on High-Pressure Common Rail (HPCR) systems to deliver fuel at astonishing pressures (often exceeding 2,000 bar). Critical components within the fuel injection pump, pressure regulator, and injectors utilize ultra-precision bushings, sleeves, and plungers. These parts must contain this extreme pressure while allowing micron-level movements with minimal friction and zero fuel leakage.

Failure Modes & Consequences:

Erosive & Cavitation Wear: High-velocity fuel wash and pressure implosions can erode metal surfaces over time.

Corrosion: Exposure to various fuel blends and contaminants.

Scuffing & Seizure: Any failure here leads to immediate loss of rail pressure, engine misfires, power loss, and expensive injection system repairs.

Material & Technology Solution:

This is the pinnacle of bushing technology. MYWAY components for HPCR systems are engineered from specialized materials:

High-Grade, Corrosion-Resistant Steels: Such as stainless steel variants.

Advanced Surface Treatments & Coatings: Including nitriding, DLC (Diamond-Like Carbon), or super-hard chrome plating to combat wear and corrosion.

Nanometer-Level Precision Grinding: Tolerances are measured in microns to ensure perfect sealing and plunger fit, which is critical for maintaining injection pressure and meeting emissions standards.

Introducing MYWAY Bushings & Sleeves: Engineered for the Critical Moment

At MYWAY, we understand that an engine is a chain, and its strength is defined by its weakest link. Our Bimetal and Steel Sleeve product lines are manufactured not just to meet specifications, but to exceed the real-world demands of modern engines.

Why MYWAY Should Be Your Strategic Sourcing Partner:

Material Science Expertise: We don’t just supply metal; we supply optimized material solutions. Our metallurgical team selects and tests alloys for specific applications—be it the high-conformability needs of a camshaft or the extreme pressure resistance required in a fuel pump.

Precision as a Standard: Our manufacturing processes leverage state-of-the-art CNC machining, automated grinding, and 100% automated optical inspection. Every MYWAY Camshaft Bushing, Valve Rocker Arm Bushing, or HPCR sleeve delivers consistent, reliable geometry.

Durability & Performance Focus: Our products are designed to extend maintenance intervals, reduce downtime, and protect the more expensive components they support. This translates directly into lower Total Cost of Ownership (TCO) for your engines or fleet.

Customization & Flexibility: We offer full OEM-specification replacements and can work with clients on custom designs for performance applications or next-generation engine prototypes.

FAQ (Frequently Asked Questions)

Q1: Are MYWAY bushings direct replacements for OEM parts?

A: Absolutely. Our Engine Components and Fuel System Components are reverse-engineered and manufactured to match or exceed original equipment dimensions, material specifications, and performance benchmarks. You can cross-reference our Product Series Name (Bimetal/Steel Sleeve) with your OEM part number.

Q2: What makes your bimetal bushings different from others on the market?

A: The difference lies in the bond. MYWAY uses a proprietary metallurgical bonding process to ensure the inner alloy layer is perfectly and permanently fused to the steel backing. This prevents layer separation—a common failure point under extreme thermal cycling and load.

Q3: Do you offer bushings for high-performance or racing applications?

A: Yes. We work with many performance builders. For these applications, we can provide components from upgraded materials, apply specialized surface treatments, and hold even tighter tolerances to support higher RPMs and aggressive cam profiles.

Q4: What is your minimum order quantity (MOQ) for these precision bushings?

A: We understand the needs of both large distributors and smaller repair shops. We offer competitive MOQs and are flexible. Contact us directly to discuss your specific volume requirements.

Q5: How can I request a quote or technical datasheet for a specific engine model?

A: Simply visit our website’s contact page or email our technical sales team. Provide the engine model, OEM part number, or a sample of your current bushing. We will respond promptly with a quotation, technical specifications, and compatibility confirmation.

Conclusion: Partner for Precision, Source for Strength

Choosing the right bushing is a technical decision with significant commercial implications. In the critical junctions of the camshaft, rocker arm, and fuel injection system, there is no room for compromise.

MYWAY stands as a dedicated manufacturer committed to providing the precision, durability, and reliability that these systems demand. We invite OEMs, distributors, and master rebuilders to connect with us. Let’s discuss how our Bimetal and Steel Sleeve solutions can enhance your product’s performance or streamline your repair operations.

Ready to specify the right component for your critical application? Contact the MYWAY engineering and sales team today for a consultation and quote.