MYWAY Bushing: Automotive Oil Pump and Power Steering Pump Bushing Solutions

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Automotive » Automotive Oil Pump and Power Steering Pump Bushings

MYWAY Automotive Oil Pump and Power Steering Pump Bushings

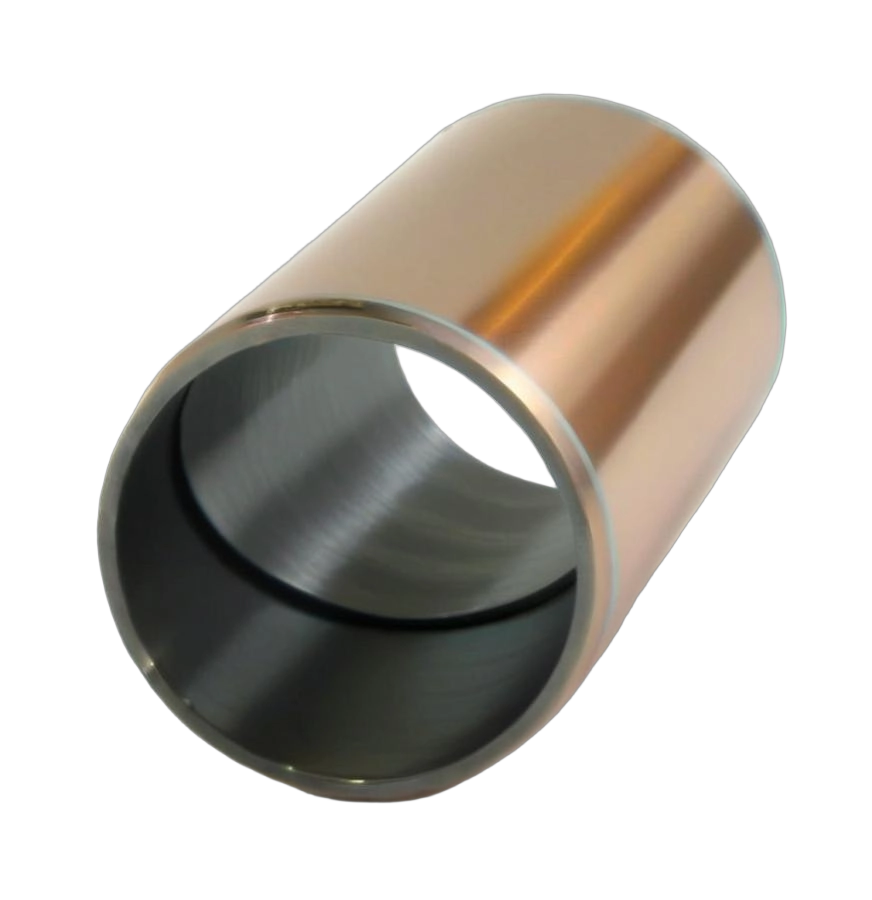

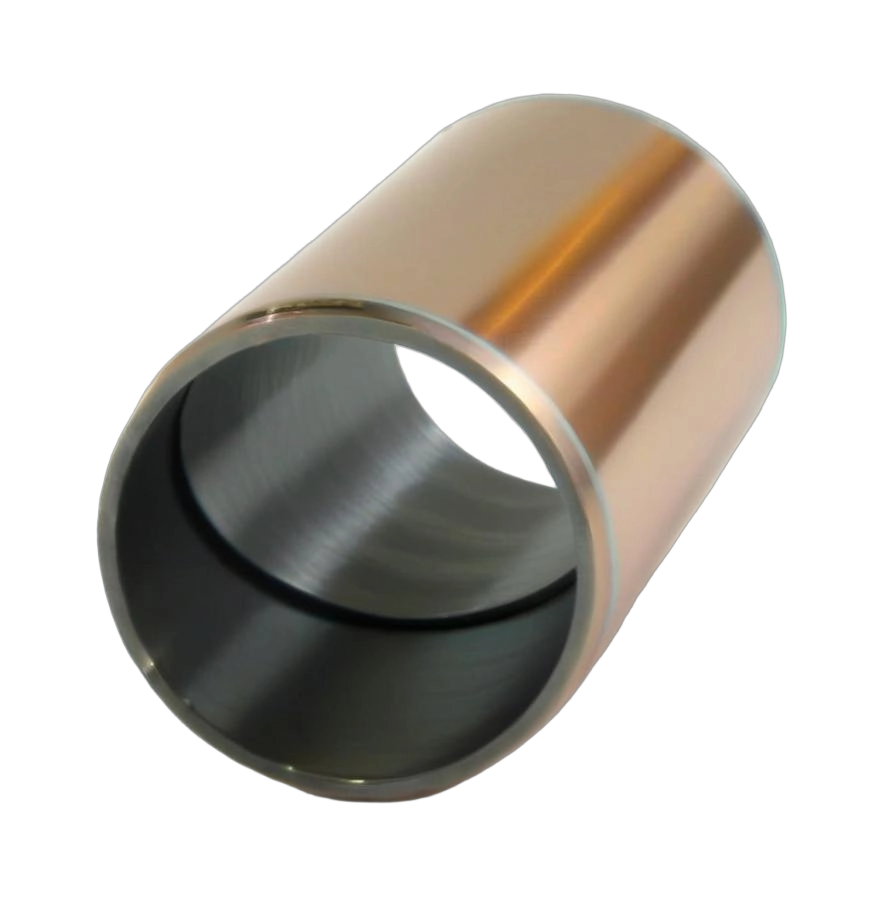

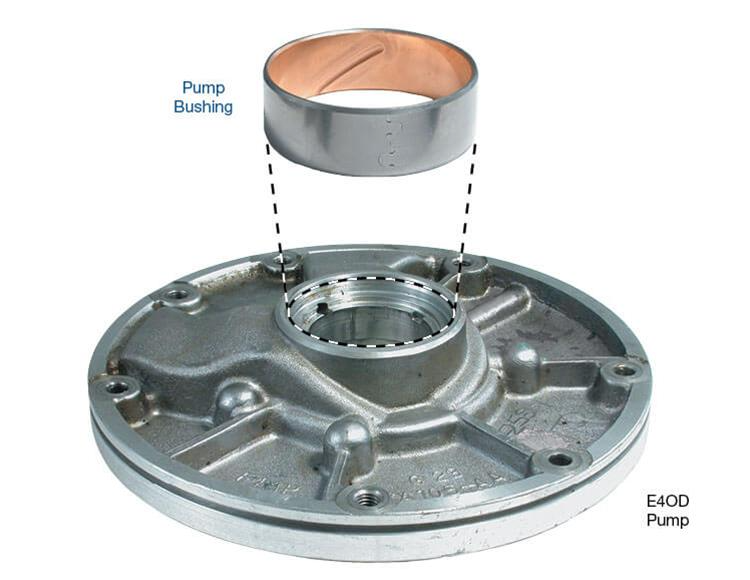

Automotive Oversized Pump Bushing 85916-01

Sonnax oversized pump bushings 85916-01 and 85916-01U contain one pump bushing each to allow rebuilders to salvage pumps with damaged bushing bores. Specs Bushing Style: Precision Material: Bimetal Width: 0.533" Shaft Dia.: 1.774" Housing Bore: 2.002"

Toyota Front Pump Bushing A340 AW4 U140E U240E U241E U140F 99-On A210 A240 85-01

Automatic transmission front pump bushing. AW80-40LS, GM 1999-On. AF33-5, AF23-5, RE5-F22A, RE5F22A, AW55-50SN, AW55-51SN Pontiac GM Saturn Suzuki Infiniti Nissan Saab Volvo Aisin Warner Automatic Transmission 2001-On. GM MX17, 1985-2001 Lexus Pontiac U240-E, U241-E, U140-F, 1999-On.

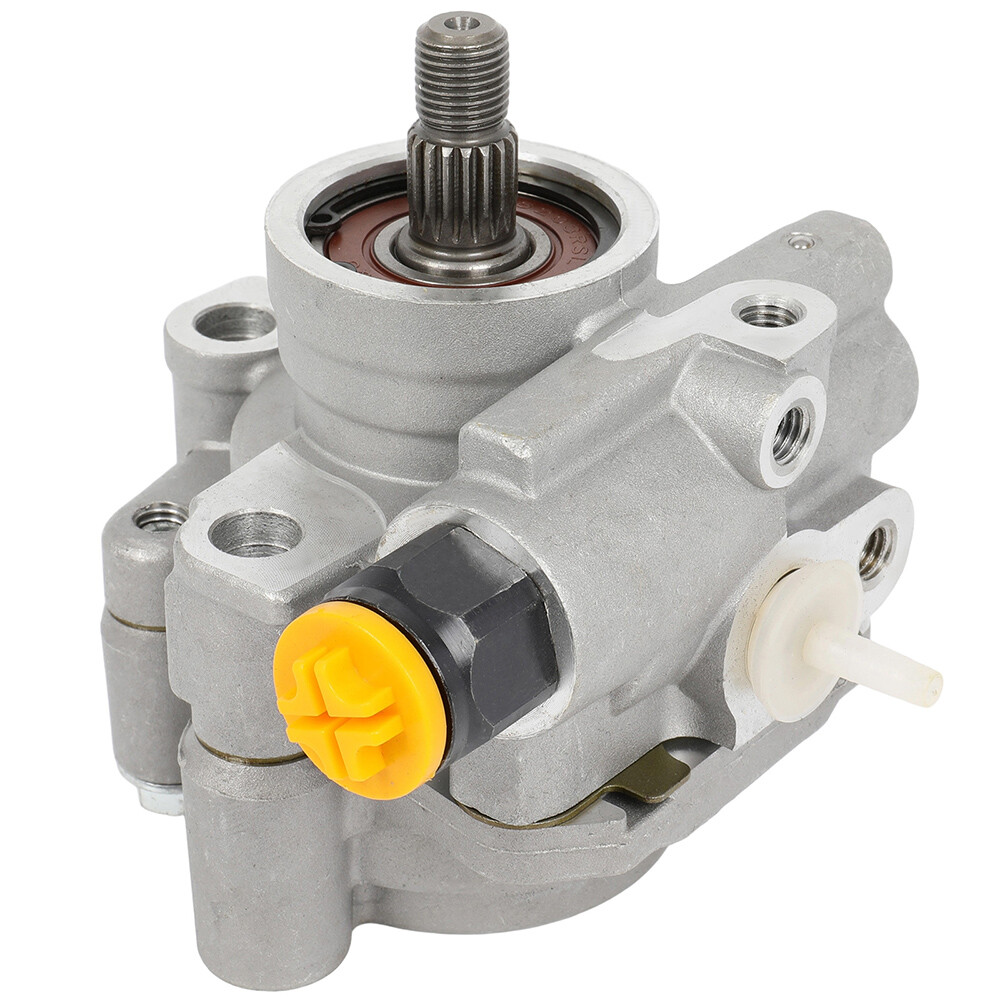

Automotive Power Steering Pump Bushings

Automotive Power Steering Pump Bushings

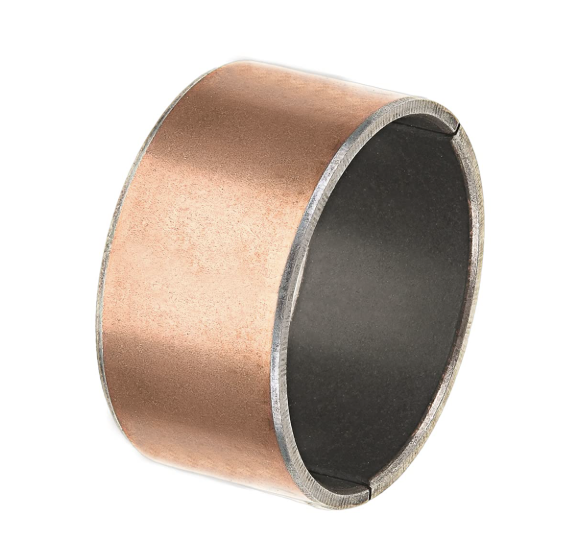

Automotive Pumps - Oil Pump and Power Steering Pump Bushing

Automotive Pumps - Oil Pump and Power Steering Pump Bushing

Automotive Pumps - Oil Pump and Power Steering Pump Bushing

Automotive Pumps - Oil Pump and Power Steering Pump Bushing

10000+ Types of TAutomotive Oil Pump and Power Steering Pump Bushings – Contact Us for Details

| Component Category | Specific Type / Model | Product Series Name |

| Automotive Oil Pump and Power Steering Pump Bushings | Bimetal Bushings | Bimetal Bushing Series |

| Self-Lubricating Bushings | Self-Lubricating Bushing Series |

The Heartbeat of Your Engine: Why Bushing Quality is Non-Negotiable for Oil and Power Steering Pumps

In the symphony of a running engine, two pumps work in concert to ensure its life and drivability: the oil pump, circulating the vital lifeblood, and the power steering pump, translating driver effort into smooth, effortless turns. While often overlooked, a small, precision component sits at the operational core of both: the bushing. More than just a simple sleeve, it is the critical interface that ensures alignment, minimizes wear, and dictates the longevity of the entire pump assembly.

Choosing the right bushing isn’t just a procurement decision; it’s a direct investment in reliability, performance, and cost-effectiveness. This guide dives deep into the role of bushings in automotive pumps and explains how MYWAY’s advanced bushing solutions are engineered to meet the exacting demands of modern and remanufactured pump assemblies.

The Critical Role of Bushings in Pump Performance

Bushings in oil and power steering pumps serve one fundamental purpose: to provide a perfectly aligned, low-friction, and durable bearing surface for rotating shafts. Their failure is never an isolated event; it cascades into total pump failure.

| Pump Type | Core Function of the Bushing | Consequences of Bushing Failure |

|---|---|---|

| Oil Pump | Aligns and supports the pump gears or rotor shaft, maintaining precise internal clearances (typically between 0.0004 to 0.0025 inch for gear-to-housing clearance). | Loss of oil pressure, catastrophic engine wear due to metal-on-metal contact, and total engine failure. In some engine designs, a failed oil pump bushing can necessitate replacing the entire engine block. |

| Power Steering Pump | Supports the pump’s drive shaft, ensuring smooth rotation against hydraulic pressure. Prevents shaft “walk” that destroys seals. | Shaft misalignment leads to rapid seal wear, fluid leaks, noise (whining/groaning), loss of steering assist, and eventual pump seizure. |

A telling case study from SPIROL highlights the cost of tolerance errors. In an oil pump assembly, using a solid dowel bushing required an expensive reamed hole with ultra-tight tolerances. An oversized bushing could damage the housing during press-fitting, while an undersized one could lead to play and eventual pump failure. Switching to a standard, compliant bushing design that could conform to the hole saved the customer 50% per part and eliminated a costly machining step. This underscores that the bushing itself must be engineered as intelligently as the system it serves.

What Makes a High-Performance Pump Bushing? Material and Design

Not all bushings are created equal. The extreme environment inside an automotive pump—subjected to high pressures, temperature swings from cold starts to engine operating heat, and constant chemical exposure to oils and additives—demands specialized materials and precision manufacturing.

1. The Foundation: Superior Bearing Materials

The base material is paramount. Bronze alloys, particularly self-lubricating varieties, are the gold standard for these applications. They offer an ideal balance of strength, thermal conductivity to dissipate heat, and excellent wear resistance. At MYWAY, our proprietary bronze blends are formulated to provide superior embedability (the ability to absorb small abrasive particles) and consistent performance across the required temperature range, outperforming generic brass or sintered alternatives that may fail under stress.

2. The Seal’s Best Friend: Compatible and Durable Seal Surfaces

The bushing’s inner diameter is the running surface for the pump’s shaft seal. Any imperfection here will accelerate seal wear and cause leaks. Modern pumps, especially remanufactured units from leaders like CARDONE, use advanced seal materials like Hydrogenated Nitrile Butadiene Rubber (HNBR). HNBR offers exceptional resistance to heat (operating from -40°C to +165°C), power steering fluid, and engine oils. A high-quality bushing must have a fine, consistent surface finish (a low Ra value) to ensure these premium seals achieve their full service life without grooving or cutting.

3. The Key to Longevity: Precision Tolerancing and Alignment

As detailed in our specialized guide on Press Fit Tolerancing, the bushing’s outer diameter must achieve a perfect interference fit (e.g., H7/p6 per ISO standards) within the pump housing. This prevents any micro-movement (“creep”) that leads to wear and misalignment. “Precise bushing alignment prevents premature shaft and seal wear, significantly reducing noise and vibration,” a principle critical to both new and remanufactured pumps. Achieving this requires not just precise OD tolerances but also absolute concentricity between the ID and OD, ensuring the shaft rotates perfectly on-axis.

A Guide for Engineers and Remanufacturers: Selection and Diagnosis

Choosing the Right Bushing for Your Application

For Critical, High-Load Locations: In applications like an oil pump’s idler gear shaft or a power steering pump’s main shaft, opt for a solid or heavy-walled bronze bushing with a precise press-fit tolerance. Material consistency is non-negotiable.

For Alignment and Dowel Applications: Consider standard, compliant dowel bushings like the SPIROL Series DB100. These can simplify assembly, forgive minor hole variations, and reduce overall cost without sacrificing reliability.

Always Specify Surface Finish: Clearly call out the required surface roughness (e.g., Ra 0.4μm) for the seal-running ID to match the quality of the seal being used.

Troubleshooting Bushing-Related Pump Failures

When diagnosing a failed pump, don’t overlook the bushing:

Low Oil Pressure or Pump Whine: After disassembly, inspect the bushing for scoring, galling, or excessive clearance. Use precision gauges to check the manufacturer-specified gear-to-housing or shaft-to-bushing clearance.

Persistent Power Steering Leak After Seal Replacement: If a new HNBR seal fails quickly, the likely culprit is a worn or scored bushing that is damaging the seal lip. Replacing the seal without addressing the bushing is a guaranteed comeback.

Metallic Debris in Fluid: If you find metallic “glitter” in the power steering reservoir or oil, it points to active wear. The bushing is a prime suspect and should be replaced along with a full system flush to prevent abrasive damage to new components.

Engineered for Excellence: The MYWAY Advantage

At MYWAY, we specialize in manufacturing the precise, high-performance bushings that modern automotive pumps demand. We go beyond being a supplier to act as a solutions partner for OEMs and remanufacturers worldwide.

Our core strengths align perfectly with pump manufacturers’ critical needs:

Precision-Grade Materials: We use certified, high-grade bronze alloys and offer self-lubricating options, ensuring optimal performance for shaft support and seal compatibility.

Uncompromising Manufacturing Tolerances: Our processes are calibrated to consistently achieve the ISO tolerance grades (like p6, r6) required for secure, reliable press fits and perfect shaft alignment, directly addressing the leading cause of premature seal and pump failure.

Custom Engineering Support: Need a bushing for a legacy pump model, a unique material specification, or a custom wall thickness? Our engineering team can develop and prototype tailored solutions that meet exact design and performance criteria, helping you avoid costly downtime or redesigns.

Proven Quality for the Aftermarket: Our bushings are manufactured as direct replacements that match or exceed OE fit, function, and durability, making them the ideal choice for reliable remanufacturing programs.

Ready to Specify with Confidence?

Don’t let an underspecified bushing become the weak link in your pump assembly. Whether you’re designing a new system, sourcing for remanufacturing, or troubleshooting a persistent failure, MYWAY has the technical expertise and manufacturing capability to deliver the right solution.

Contact MYWAY today to discuss your specific application, request samples, or get a detailed quotation. Let us help you build pumps that are quieter, leak-free, and built to last.

FAQ: Automotive Pump Bushings

Q1: Why can’t I just use any standard bronze bushing from a general supplier?

Automotive pump applications require very specific material properties for wear, thermal expansion, and compatibility with modern fluids and seals. Generic bushings often lack the precise chemical composition, heat treatment, or tolerance control, leading to premature failure in this demanding environment.

Q2: We’re remanufacturing pumps. Is upgrading the bushing material worth the cost?

Absolutely. Upgrading to a high-performance bushing and pairing it with a premium HNBR seal is one of the most effective ways to reduce comebacks and enhance your brand’s reputation for quality. It addresses a root cause of failure, adding value and reliability that customers recognize.

Q3: How critical is the press-fit tolerance really?

It is fundamental. An improper fit—too loose or too tight—compromises the entire assembly. A loose fit causes creep and wear; a fit that’s too tight can distort the housing or the bushing itself. Adhering to ISO hole-basis system standards (e.g., H7 housing with p6 bushing OD) ensures predictable, reliable performance.

Q4: Can MYWAY help if we have a problematic existing design?

Yes. Our engineering support often begins with application review. We can analyze failure modes, recommend material or tolerance adjustments, and provide custom-designed bushings to solve chronic issues like frequent seal leaks or noise problems.

Q5: What information do you need to provide a quotation or design suggestion?

Provide as much as possible: OEM part number (if replacing), a detailed drawing, material specifications, and most importantly, the application context (e.g., “main shaft bushing for a hydraulic power steering pump, currently experiencing seal leaks after 50k miles”).